Last Updated on February 14, 2026 by Maged kamel

List of Tension Member’s Posts-part 2.

The list of tension Member’s Posts-part 2 will start from post 7 to post 9D.

- List of Tension Member's Posts-part 2.

- A solved problem 3-6 for Design strength.

- A solved problem 4-2 for shear Lag factor U.

- Two solved problems for the effective net area.

- Practice problem 3- 32: Transverse weld of a WT section.

- Practice problem 3-34- A longitudinal weld of a plate section.

- Practice problem: longitudinal weld of a C-section.

- How do you determine the effective area for a staggered bolted angle?

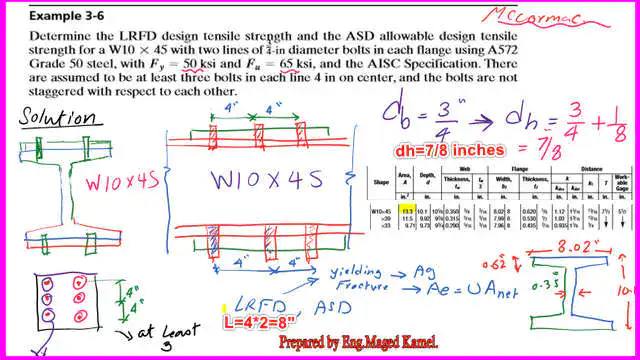

A solved problem 3-6 for Design strength.

This is the 7th post of the Tension Member’s Posts, including a solved problem 3.6 from Prof. McCormack’s book.

Determine the LRFD design tensile strength and the ASD allowable design tensile strength for two lines of -in diameter bolts in each flange using A572 Grade 50 steel, with the AISC Specification.

It is assumed that there are at least three bolts in each line 4 in the centre, and the bolts are not staggered with respect to each other.

This link is for post 7: A solved Problem for Design Strength.

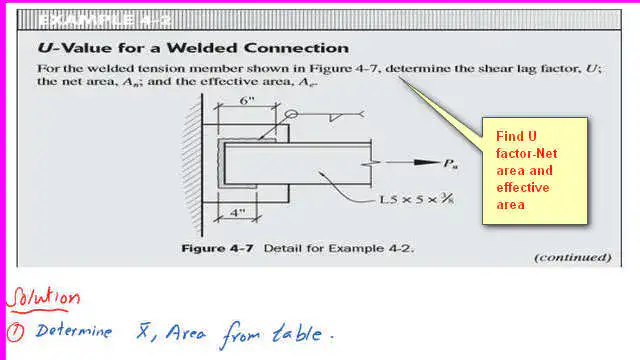

A solved problem 4-2 for shear Lag factor U.

This is the 8th post in the Tension Members’ Posts series, which includes a solved problem (4-2) from Prof. Abi O. Agaghayere’s book. The welded member is shown in Fig. 4.7. Determine the shear lag factor U, the net area Ant, and the effective area Ae.

This link to post 8: A Solved Problem 4-2 for shear Lag factor U.

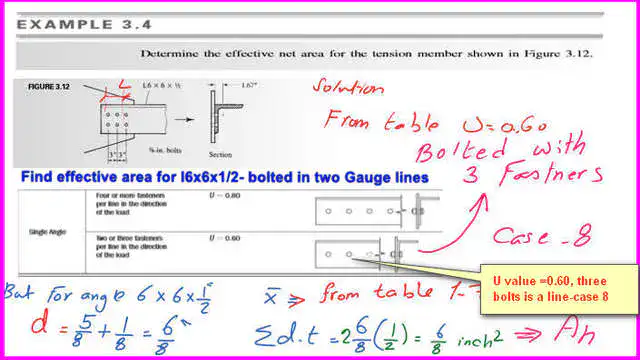

Two solved problems for the effective net area.

This is the 9th post in the Tension Member’s Posts series, including Solved Problem 3.4 from Prof. William T. Segui’s handbook. Determine the effective net area for the tension member shown in Figure 3.12.

A Solved problem 3.5, from Prof. William T Segui’s handbook.

Determine the effective area if the tension member of Example 3.4 is welded, as shown in Figure 3.13.

The link to post 9: Solved problems for the effective net area.

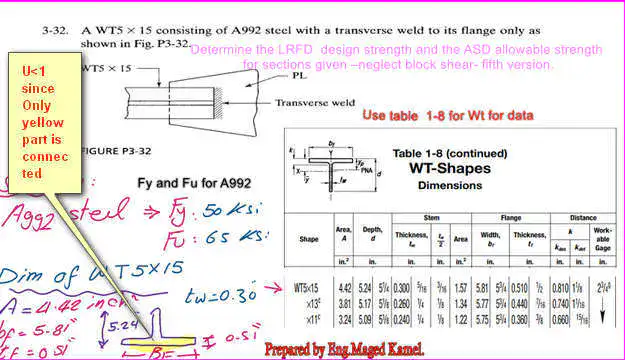

Practice problem 3- 32: Transverse weld of a WT section.

This is the 10th post of the Tension Member’s Posts, which includes a Practice problem for the Transverse weld of a WT section. This is case 3 for the shear lag factor table D3.1. A given WT5x15 section of A922 steel with a transverse weld to its flange, as shown in Figure P3-32, is required to find the LRFD and ASD values, neglecting the block shear.

This is the link to post 9a: Practice problem- transverse weld of a WT section.

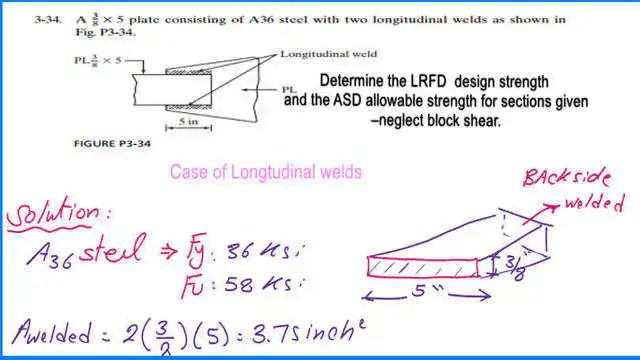

Practice problem 3-34- A longitudinal weld of a plate section.

This is the 11th post in the Tension Member’s Posts series. It includes a given WT5x15 section of A922 steel with a transverse weld to its flange, as shown in Figure P3-34, and requires finding the LRFD and ASD values, neglecting block shear. The problem was solved by using CM#14. The same problem was resolved by using CM#15.

This is the link to post 9b: Practice problem-longitudinal weld of a plate section.

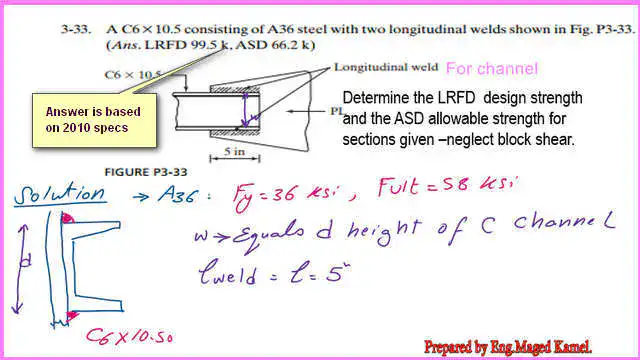

Practice problem: longitudinal weld of a C-section.

This is the 12th post in the Tension Members’ Posts series, which includes practice problems 3-33 from Prof. McCormac’s book. This Practice problem concerns the longitudinal weld of a C-section. It is case 2 for the shear lag factor table D3.1-CM-14. Based on CM-15 and the related specification-2016, it can also be considered case 4a.

This is the link to post 9c: Practice problem-longitudinal weld of a C-section.

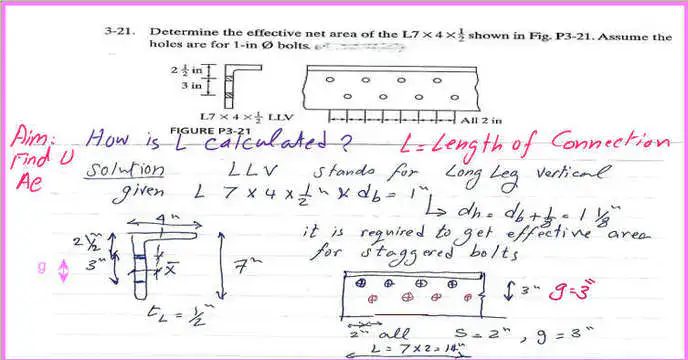

How do you determine the effective area for a staggered bolted angle?

This is the thirteenth post in the Tension Members’ Posts, which includes two solved problems. The first problem is determining the Effective Area for a Staggered Bolted Angle.

The second solved problem is determining the service load capacity of a particular bolted staggered angle. The following image represents the first solved problem.

This is the link to post 9d: How to determine the effective area for a staggered bolted angle?

This is a link to the list of tension members, part 1.

This is a link to the list of tension members ( part 1A).

This is a link to the list of tension members’ posts in part 3.

An external source for tension members from Prof. T. Bartlett Quimby’s site, which is the Tension Member Overview based on CM#15.