Introduction to Bolted Connections.

The content of PDF data.

These are the items to be discussed in this post: The first point, with god’s will, is the bolt types, there are two types the first type is Low carbon steel, the second type is high tensile steel bolts, which are the most used types of connections and can be classified to two types ASTM A325, A490.

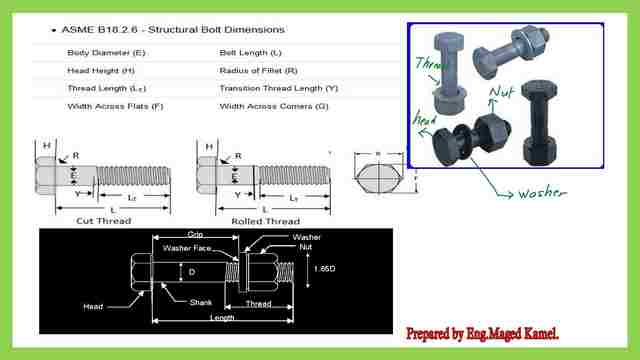

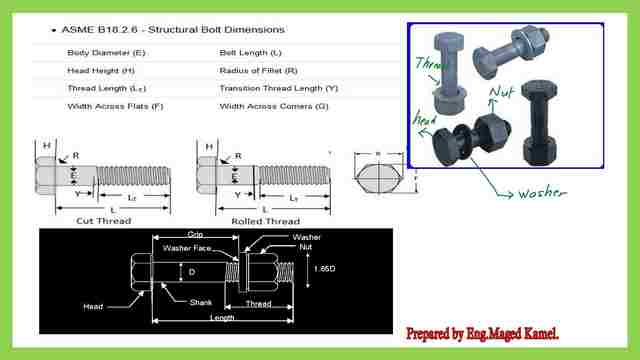

The second subject, is the structural bolt dimension, the length, and the names of the different components of the bolt.

The third subject is the related chapter in the AISC concerning connections.

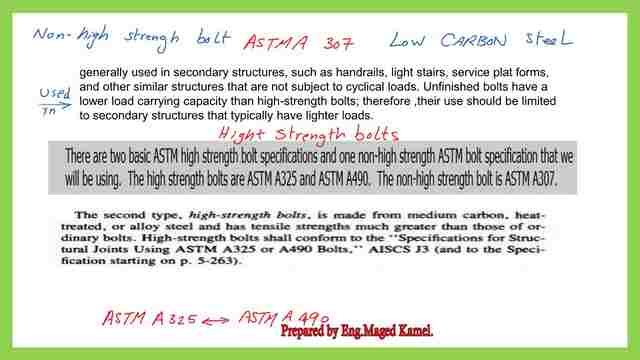

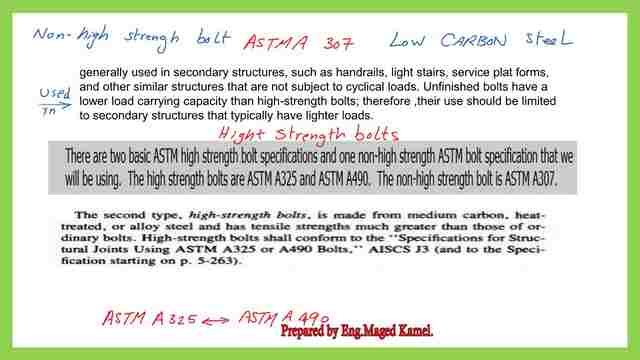

The first thing that, we have- ASTM- A -307, Low carbon steel, which was used in the secondary structures such as handrails, light stairs, service platforms, and other similar structures that are not subject to cyclic loads.

These structures have loads that do not change with time. Unfinished bolts have Lower load-carrying capacity than high-strength bolts, so bolts, due to lower capacity are used in secondary structures, which have a lower load capacity acted upon by lighter loads. The second subject is the High- strength bolts.

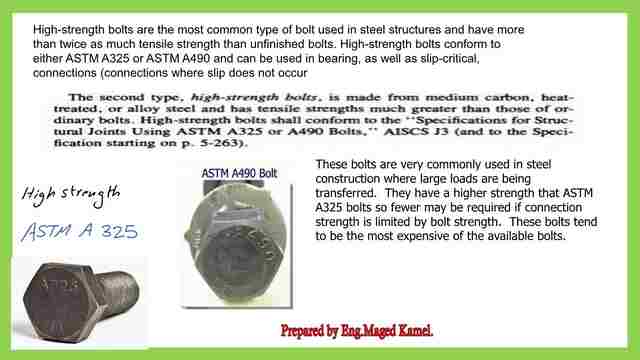

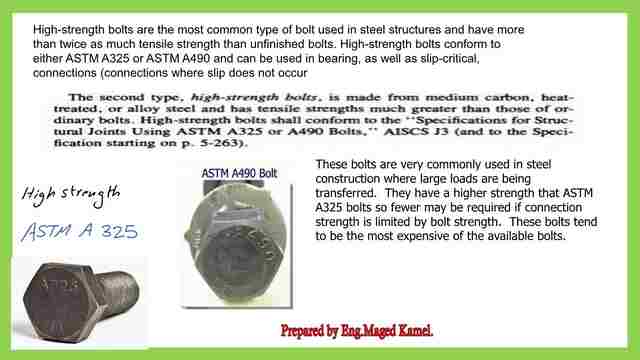

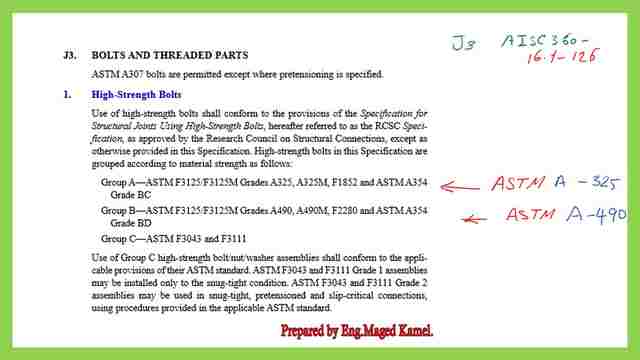

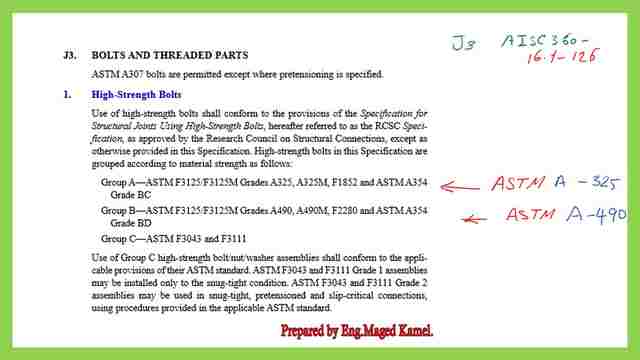

These bolts can be classified into two categories according to the ASTM specifications for high-strength bolts. We have ASTM A 325& ASTM A 490. The non-high strength bolt is ASTM A307, Which we discussed earlier.

The high-strength bolts are made from medium carbon, heat-treated, which has a tensile strength much greater than those of ordinary bolts. The strength of these bolts is much greater than ASTM A307 bolts.

The different components of High-strength bolts for bolted connection.

For the shape of bolts. I quote, that high-strength bolts are the most common type of bolt used in steel structures and have more than twice as much tensile strength as unfinished bolts.

This is a sample of ASTM A325 for one of the suppliers, it is written on the head and the symbol of U for unfinished.

The second bolt sample is for ASTM A 490 bolt. Again, it is written on the head and the symbol of ASTHMA 490.

I quote, these bolts, ASTMA490 bolts, are very commonly used in steel construction where large loads are being transferred. they have higher strength than ASTM A325 bolts so fewer may be required if connection strength is limited by bolt strength. This is the advantage of using a higher strength bolt, to minimize the number of bolts used for the connection.

This is the part that deals with the types of bolts and their components for bolted connections. This is the head of the bolt with a shank, which is the smooth part of a fastener above the threads followed by a thread.

This is the washer shown in these two sections. The next part is the nut. Here again, is shown. When we use the washer and nut in the threaded portion.

The bolt length can be divided into two parts, the first part is the head the shank, and part of the thread till the washer.

This is called grip. The threaded part is shown in the sketch, The total length of the bolt is the shank + the threaded length. The diameter of the washer is specified as 1.65D. it is written, body diameter E as in the cut thread picture. The bolt length L. E is the round portion. H is the head height. The thread length is Lt. The transition thread length Y. as shown here in the picture. G is the width across corners.

Classification of the High-tensile bolts according to section J3 for bolted connection.

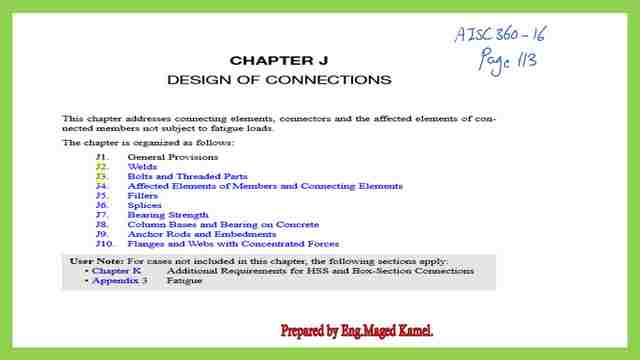

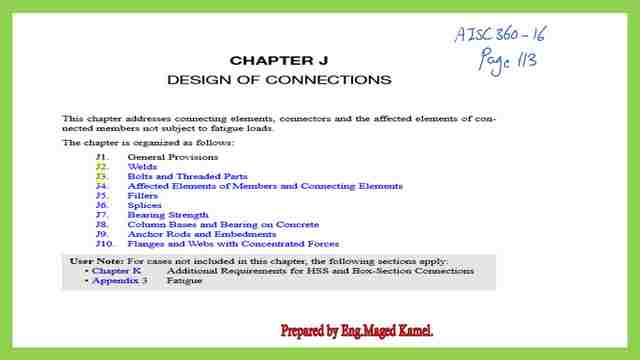

What about the chapter that deals with the design of connection in the AISC? it is chapter J. If we need to check the welded connection, the relevant section is J2.

High-strength bolts for bolted connection.

In chapter j- part j3, Bolts and threaded parts at item 1, the code describes the high-strength bolt and classifies the bolts into Group A and Group B.

When dealing with bolt A325 it is included in group A.

If in a given problem, it is mentioned that the bolt is of group A. then, it is the ASTM A325 bolt. If he wishes to include bolt ASTM A 490, then it is in the group. Also, there are two categories, whether threaded included or excluded for bolted connection. This other classification will be discussed in God’s will next time. What about the snug tight and fit?

The snug tight bolts for bolted connection.

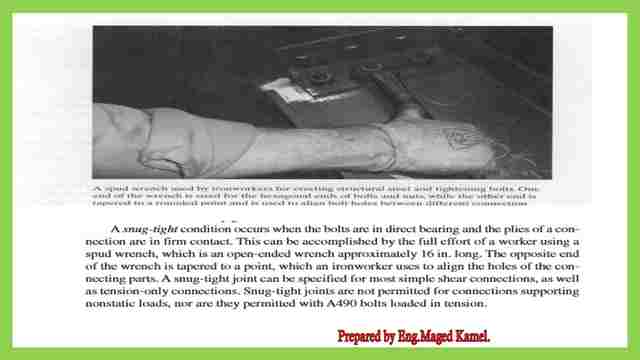

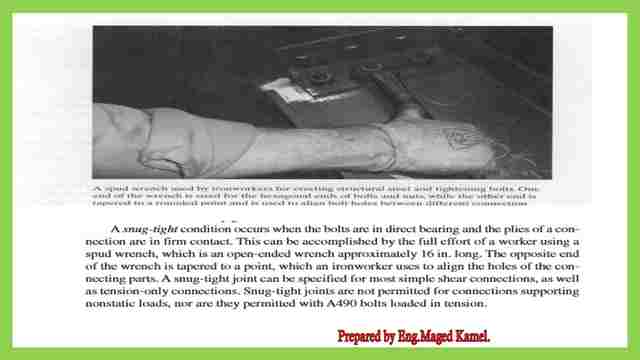

As we can see in the picture, the bolts in the base plate are placed and need to be tightened in the picture, there is an intersection of two angles. This is a Structural part, maybe a pedestal, not clear.

then tightenings by spanner which is a spud wrench which is an open-ended wrench approximately 16″ long. So by torque produced by the spud, the bolts are tightened There is another way which is called pre-tensioning. This type of connection is called a shear connection. I quote, The snug-tight can be specified as a shear connection, as well as tension-only..connections.

The snug-tight is not permitted for connections supporting non-elastic loads nor are they permitted with ASTM A 490 loaded in tension.

For a useful external resource, Chapter 4 for bolted connection.-A Beginner’s Guide to the Steel Construction Manual, 14th ed.

The next post is Bearing Type connections -part -1- discussion includes -types of bearing bolts.-Types of failure for the bolted joint.