Last Updated on February 25, 2026 by Maged kamel

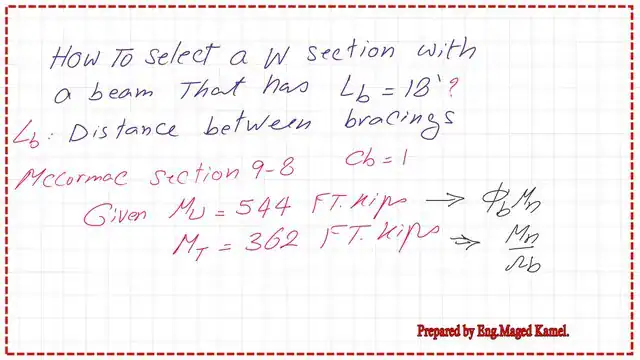

How to design a beam using design chart with a given lr?

It is required to design a beam section for cb=1, Fy =50 ksi, under Ultimate moment Mult= 544.0 ft kips, Ma=362 ft-kips, and given bracing length Lbr=18′.

Discussion of Table 3-10, design chart.

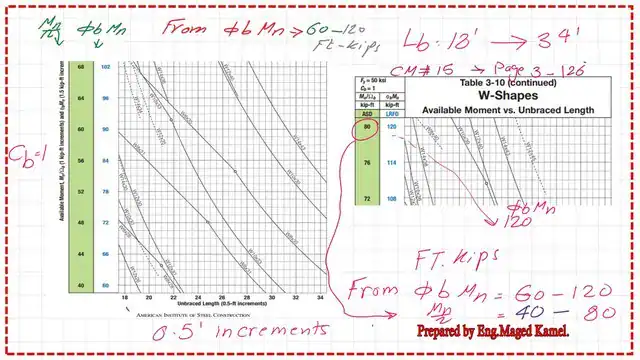

Table 3-10, design chart, from the construction manual-15. Table 3-10 is the graphical representation of Table 3-2, in which all W sections are sorted based on Zx.

The start page for W sections is on page 3-92, for Cm#15. The final page for Table 3-10 is page 3-127. Page 3-128 includes a table for the W-shape. On the next slide, in the left-hand (Y-axis) column, we can see the values for both factored φb*Mn for the LRFD design and Mn/Ωb for the ASD design. As for the X axis, it includes the bracing length, lb, which starts from 0 ft to 18′ as shown in the next slide.

The value of φb*Mn ranges from 0 to 60 ft-kips & for Mn/Ωb, it ranges from 0 to 40 Ft-kips; accordingly, since φb*Ωb = 1.50.

The next slide image shows another page of Table 3-10, where the horizontal axis is from 18 feet to 34 feet. The value of φb*Mn ranges from 60 to 120 ft-kips & for Mn/Ωb, it ranges from 40 to 80 Ft-kips; accordingly, since φb*Ωb = 1.50.

This is the first page of Table 3-10 on page 3-92 from CM#15. For the design of W-sections, the value of φb*Mn ranges from 7,500 to 12,000 ft-kips & for Mn/Ωb, it ranges from 5,000 to 8,000 Ft-kips; accordingly, since φb*Ωb = 1.50.

How do you determine the proper section for a beam using the design chart in AISC Table 3-10?

For A given Mult=544.0 ft-kips and cb=1, lb, the bracing length=18′, the appropriate page is page No.3-155, from which φb*Mn starts from 450 to 600 ft-kips & for Mn/Ωb it starts from 300 to 450 Ft-kips, lb from 0 feet to 20′.

The following steps are shown in the next two slides: draw a horizontal line for the value of Mult or φb*Mn=544 ft-kips between φb*Mn =450-600 ft-kips. Step 2: Draw a vertical line from lb=18′. Select the first solid line on the right side at the intersection of these two lines. Do not select any dotted lines, as they represent an uneconomic solution.

Check the first solid section, which will be W24x88. If the factored moment is 544 Ft.kips, the section will give a value.

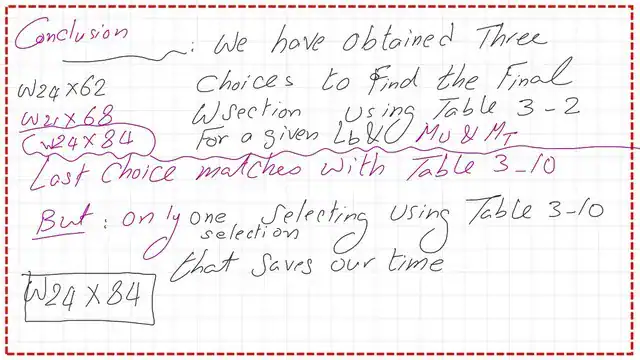

Comparison between using Table 3-10 and Table 3-2.

Suppose we will design the steel beam as a W-section using Table 3-2. As the selection for W sections is based on Z-sections, what will be our procedures?

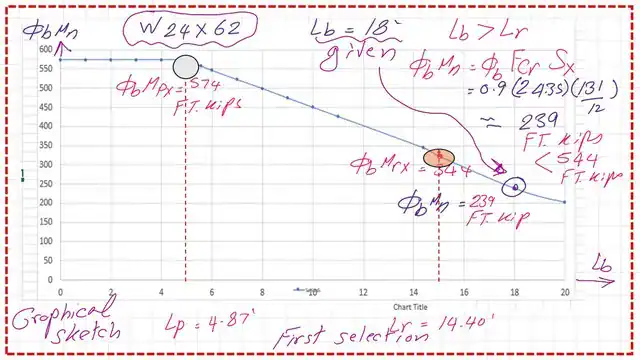

The first choice for the design of a steel beam.

1- Get the Z value of the section based on the relation Zx=Mult/Φb*Fy, which, as per the given data, will be 145.0 inch3.

2- Proceed to Table 3-2 to select a higher value of Zx,>145.0 inch3.

Our first choice will be W24x62, which has a plastic section modulus value of Zx = 153.0 in³.

Our Lp=4.87′ and Lr=14.40′, with a given Φb*Mn=570.0 ft-kips for Lp=4.87′, and Φb*Mr for Lr=344 Ft-kips.

Please refer to the next slide for more details.

Please refer to Table 3-2 for the relevant data for section W24x62.

3-Since our bracing length lb =18′, which is > Lr, the section carrying capacity is <344 ft-kips, but our given Mult is 544 ft-kips, so the section cannot have the given Mult, so this option is not satisfactory.

I have included a graph of Φb*Mn vs. Lb for W24x62, the first choice; it is clear that the moment strength is less than Φb*Mr.

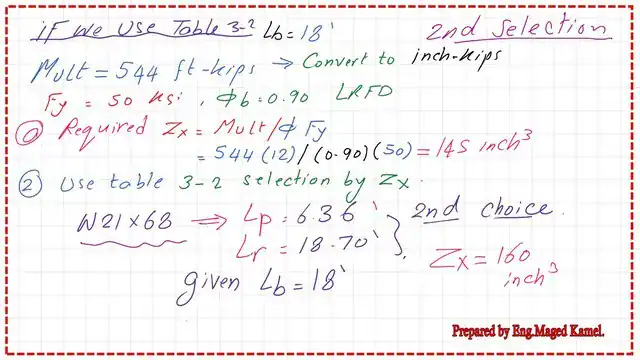

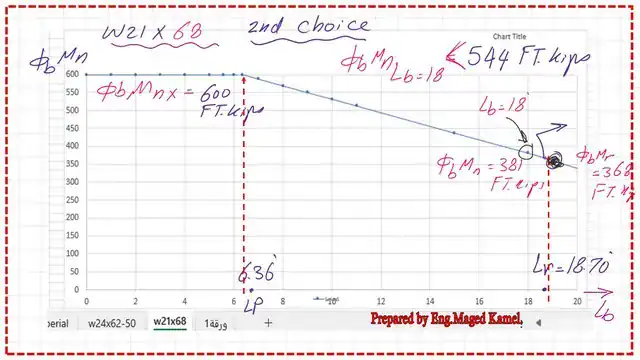

The second choice for the design of a steel beam.

1- For the second option, we proceed to W21x68 with Zx=160.0 inch3, we can find that Lp=6.36′ and Lr=18.70′, with a given Φb*Mn=600.0 ft- kips Lp=6.36′, and Φb*Mn for Lr=368 Ft-kips.

2- Since our lb =18′, then the Φb*Mn is between 600 and 368 Ft-kips, exactly =369.0 ft-kips, which is <Mult=544.0 Ft-kips, so again, the section can not carry the given Mult, then this option is not satisfactory.

Please refer to Table 3-2 for the relevant data for section W21x68.

I have included a graph of Φb*Mn vs. Lb for W24x62, the second choice; it is clear that the moment strength is less than Φb*Mr.

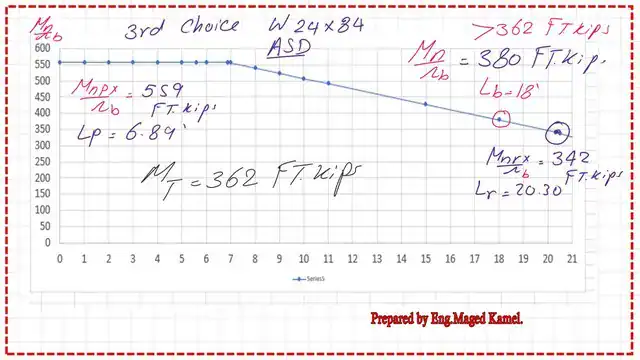

The third choice for the steel beam design complies with Table 3-10.

This is the relevant data for the third choice, W24x84, with Lp = 6.89′ and lr = 20.30′. The good news is that Lb is between the LP and Lr values. The Zx value is 224 inch3.

Please refer to Table 3-2 for the Lp and Lr data for the W24x84 section. The given factored Φb*Mpx=840 ft- kips for Lp=6.36′, and Φb*Mn for Lr=515 Ft-kips.

LRFD design data for W24x84.

I have included a graph of Φb*Mn vs. Lb for W24x84, the third choice; it is clear that the moment strength is less than Φb*Mr.

ASD design data for W24x84

Select W24x84 for cb=1. This is the check for the ASD; the selected section has a carrying capacity of Mn/Ω = 380 ft-kips, which exceeds 362.0 Ft-kips as given. Mp/Ω=559 ft. kips and Mrx/Ω=342.0 ft.kips

Please refer to the next graph for more details.

The last slide includes the advantage of using Table 3-10 over using Table 3-2. Table 3-10 has facilitated the final choice of w24x84 to match the given requirements.

The PDF file used for post 15’s content is available for viewing and download.

As an external resource –A Beginner’s Guide to Structural Engineering–Chapter 8 – Bending Members-14 ths edition.

As an external resource –A Beginner’s Guide to Structural Engineering–Chapter 8 – Bending Members-15 ths edition.

As an external resource –A Beginner’s Guide to Structural Engineering–Chapter 8 – Bending Members-16 ths edition.

For the next post, A Solved problem 4-7 designusing Table 3-10 when Lb>Lr.