Last Updated on February 18, 2026 by Maged kamel

Introduction to Plastic Theory for Beams.

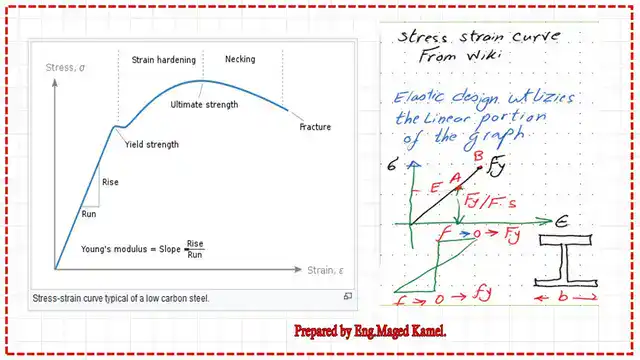

The topics for our discussion are shown on the next slide. The regions show the relationship between stress and strain for mild steel under tension.

The elastic design utilises the linear portion of the graph; the upper and lower fibres of the section will have f = Fy.

Allowable working stress design (AWSD ): quick revision.

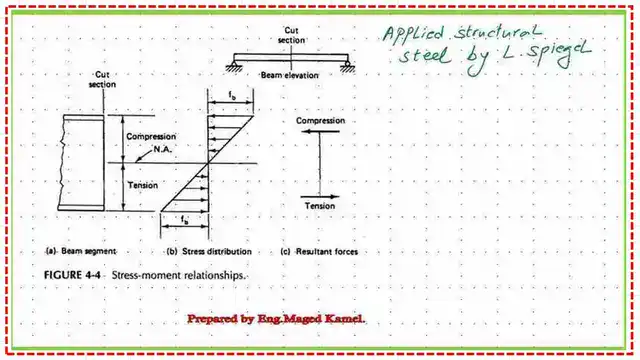

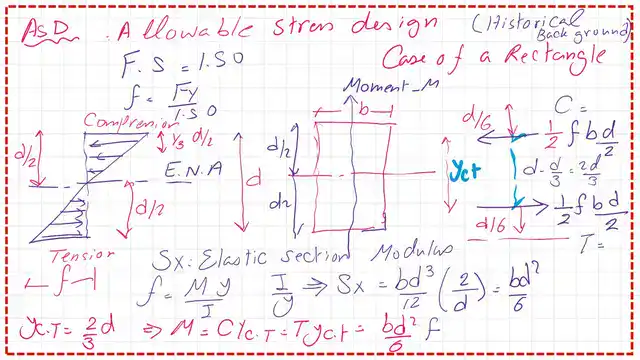

We will start to review the allowable working stress design method in which the compression force acts at a distance of (1/3)*d/2 = d/6 from the upper fibre of the section, while the Tension force acts at a distance of d/6 from the lower fibre.

The lever arm of C or T =((d-2*(1/6))=2/3d, which is the distance between the points of application between the compressive force C and the tensile force T, and sometimes called Yct, is the compression and tension, Yct =2/3d.

The Moment value =f(*b*d^2/6), the value of (b*d^2/6) is called the elastic section modulus and denoted by the symbol S. So the moment can be expressed as the product of f*S.

The stress distribution diagram for a section is shown when the design is based on the working stress, with a maximum value at the extreme upper fibre, fb. The distribution shown is linear, and the stress is zero at the neutral axis.

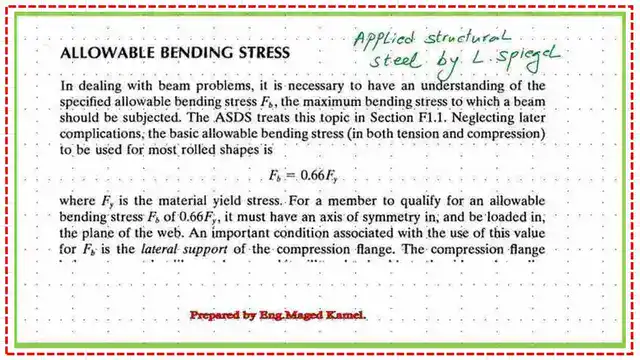

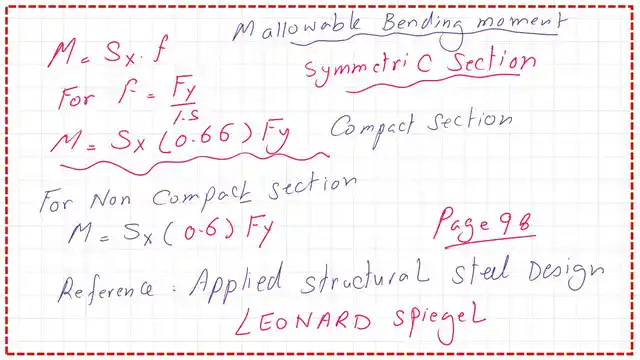

The moment of resistance of the section can be estimated from the value of Fb and the section modulus S, which is the inertia/(h/2) for a rectangular section, where h is the overall height of the section.

Again, the moment is MR= Fb*S. The maximum stress in the compact section was assumed to be 0.66Fy.

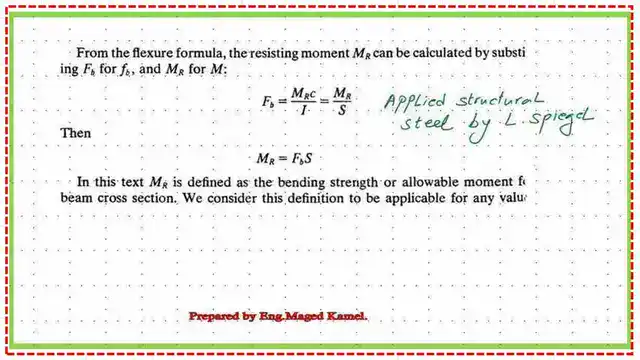

The relation between the applied moment and the stress at the upper fibre.

This provides more detail on the relationship between Moment and working stress, and on how to derive the expression.

The triangular stress was converted into two equal forces acting at (2/3 )of (d/2) from the neutral axis, creating a moment equal to the product of T*Yct or c*yct, where yct is the distance between the points of application of C&T forces.

We can derive the final expression by considering the elastic section modulus x as the value of (I/y).

The Plastic Theory.

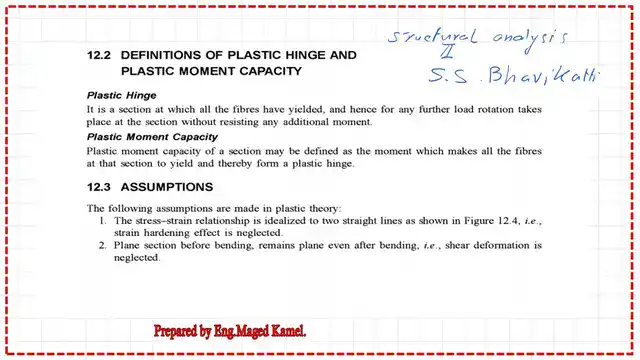

The plastic theory holds that at points of maximum moment, the section can be regarded as carrying stresses equal to the yield stress, leading to the formation of plastic hinges. At these hinges, there is no longer any capacity to carry further load, and collapse will occur.

The following assumptions are made:

1-The stress-strain relationship is idealized into two straight lines, as shown in the figure.

2- The plane section before bending remains the plane even after bending.

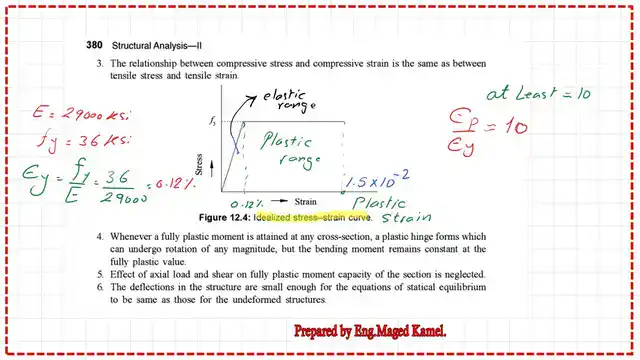

3-The relationship between compressive stress and compressive strain is the same as between tensile stress and tensile strain.

4-Whenever a moment is attained -at any cross-section, plastic hinge forms, which can undergo rotation of any magnitude, but the bending moment remains constant at the fully plastic value.

5- The effect of axial load and shear on the full moment capacity of the section is neglected.

6-The deflections in structures are small enough for the equations of statical equilibrium to be the same as those for the undeformed structures.

The strain value at the plastic stage/strain at the yield stage is approximately 10. The strain at the stage can be set to 1.50*1/100, as shown in the next picture.

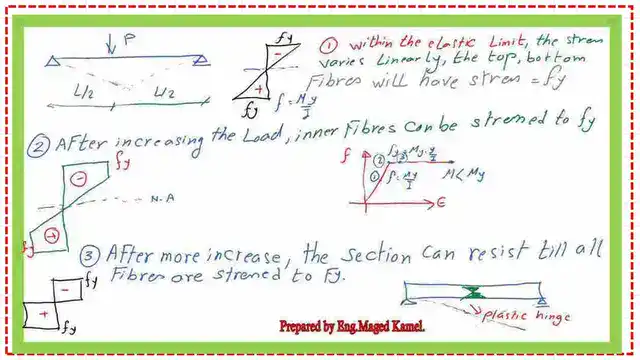

The next slide shows the stages for a rectangular section under applied loads. The elastic stage is where the extreme upper and lower fibers have reached Fy.

Next, under increasing loads, the stresses at the extreme fibers cannot exceed Fy. The lower fibers then develop stresses equal to Fy, but some fibers have not reached Fy; this stage is called elastic-plastic.

After a further increase in loads, all the rectangular-section fibers have been stressed to Fy at the plastic stage. Please refer to the next picture so the section can carry the moment.

The PDF file for this post can be viewed or downloaded from the following link.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 16th ed.

This is a link to Post 3a: Elastic and plastic section moduli for a rectangle.