Last Updated on February 11, 2026 by Maged kamel

How do you determine the effective area for a staggered bolted angle?

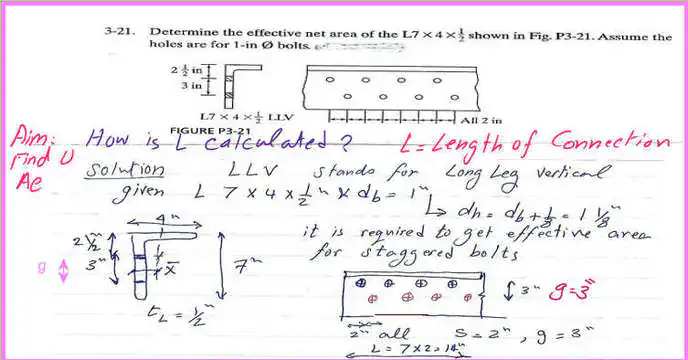

In this post, I’ll discuss a solved problem involving the effective area of a staggered bolted angle. Problem 3-21: Determine the effective area of L7x4x1/2, as shown in Figure P3-21. Assume the holes are for 1-inch bolts.

The angle is called LLV, which stands for Long Leg Vertical. We have two lines of bolts in the long leg. The first line of bolts is 2 1/2 inches from the edge, and the gap between the two lines of bolts is 3 inches.

There is a concept of connection length; how do we measure it?

The first solved problem is determining the effective area of a staggered bolted angle.

In this problem, we have an equal number of bolts distributed in two rows. These bolts are staggered, and the connection length is to be from the first bolt in the first row to the last bolt in the second row.

The diameter of each bolt is one inch. We need to add 1/8 inch to the bolt hole diameter, which will be 1 1/8 inches.

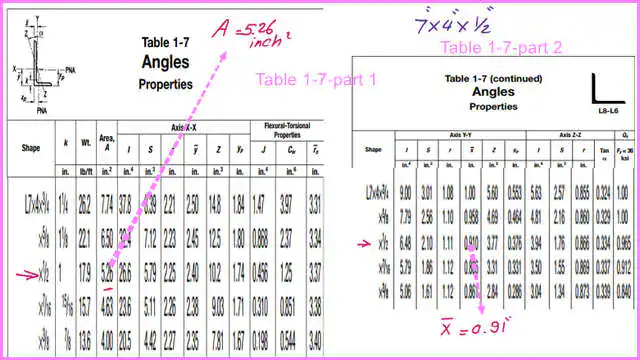

We can get the area for L7x4x1/2 from the table; it equals 5.26 in^2. The length of the connection will be (7*2=14 inches). The X bar distance is 0.91″.

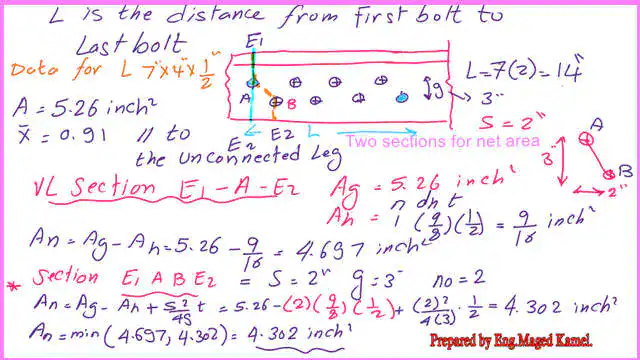

Estimation of the net area.

We will check the minimum net area for the given angle by inspecting the first route line, EAE, which is a vertical line passing by one hole.

The net area is the gross area minus the area of holes. In this case, the net area is 4.697 in^2.

We have staggered bolts. We will check another route, E ABE’, which passes by two staggered bolts. The distance g is 3 inches, which is the vertical distance between the bolt lines, while the spacing s is the distance between bolts in the direction of the load. S equals 2 inches.

For the second route, we will add the area of the staggered path and subtract the area of the holes, or the area of the two holes, from the gross area of the angle.

The final net area for the second route is 4.302 in^2, which is less than the net area estimated for the first route.

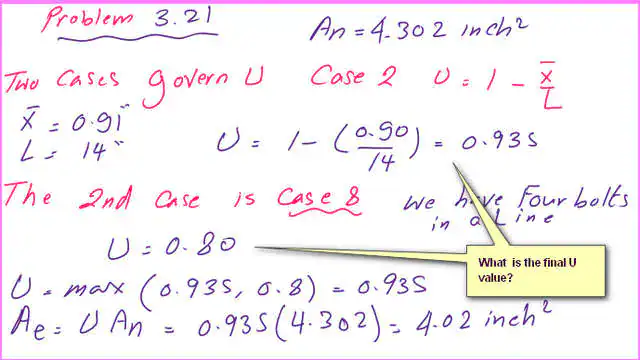

The final net area is the minimum of the two estimated values, 4.302 inch2.

Estimation of the effective area.

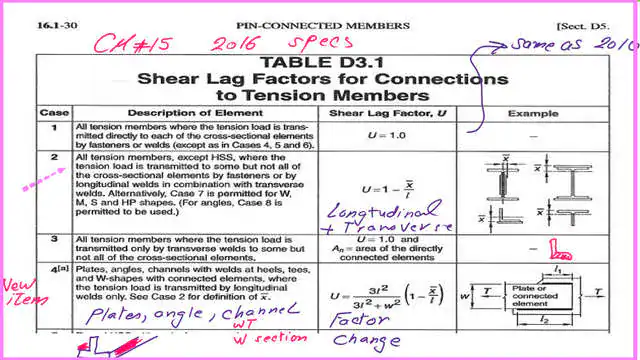

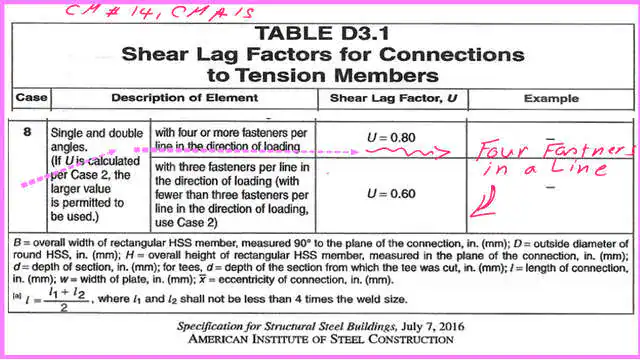

We have two cases: case 2, where the shear lag factor is U = 1 – x̅ / L. The value of U is equal to (1-x̅/L)= (1-(0.91/14)=0.935.

The second case is case 8b. When we have four or more bolts in one line, the U value is 0.80.

We will select the bigger U value, which is 0.935. Multiply U by the net area; the final effective area is 4.02 inch2.

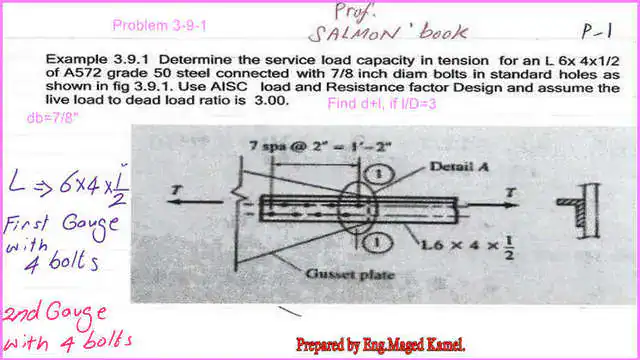

The second solved problem is determining the service load capacity for a staggered bolted angle.

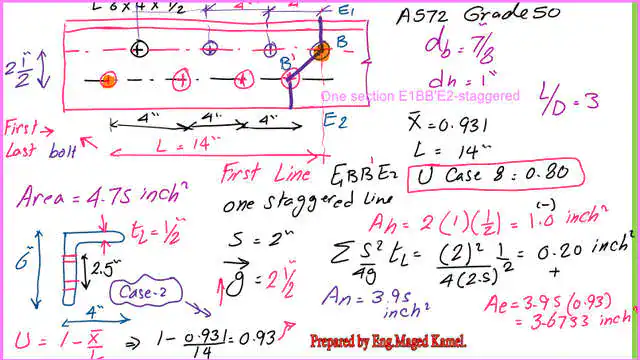

In this problem, we have an equal number of bolts distributed in two rows. These bolts are staggered, and the connection length is to be from the first bolt in the first row to the last bolt in the second row.

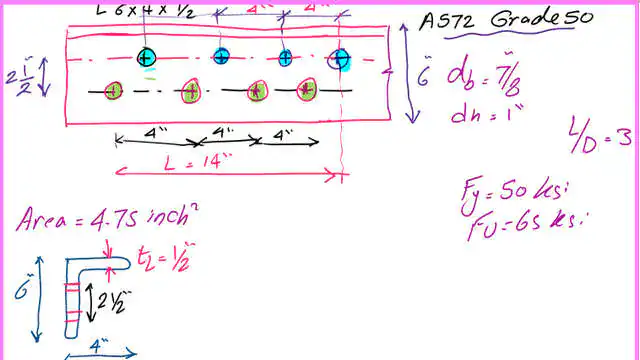

The next slide image shows the bolt arrangement for the specified angle. We add 1/8 inch for the bolt diameter to get the hole diameter.

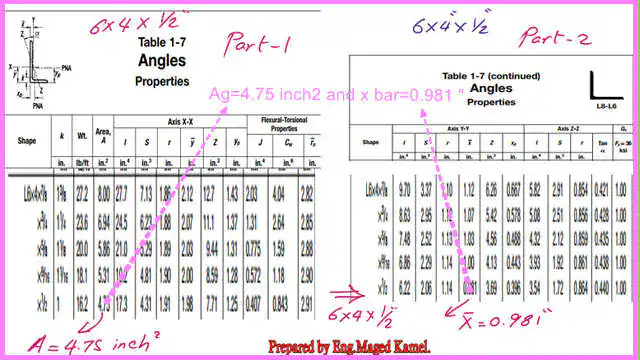

We can get the area for L6x4x1/2 from the table: 4.75 in^2. The length of the connection will be (7*2=14 inches). The x-bar value is 0.981 inches.

We have two cases to consider for the connection: case 2 and case 8.

Estimation of the net area.

We will check the route E1BB’E2. That route passes by two staggered bolts, and the distance g is 2 1/2 inches, which is the vertical distance between the bolt lines. The spacing s is the distance between bolts in the direction of the load; S equals 0.5*4=2 inches.

The first route area will pass by one bolt for which the net area equals (4.75-1*1/2*1)=4.25 inch2.

The final net area for the route is 3.95 in^2, which is less than the net area estimated for the first route.

The final net area value is the minimum of the two estimated values, 3.95 inch2.

Estimation of the effective area.

We have two cases, case 2, where the shear lag factor U=1- x̅/ L, we will estimate the value of U as equals (1-(0.981/14)=0.930.

The second case is case 8b. When we have four or more bolts in one line, the U value is 0.80. We will select the bigger U value, which is 0.93. Multiply U by the net area; the final effective area is 3.677 inch2.

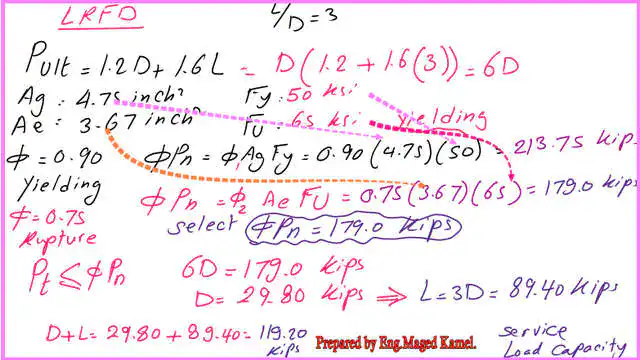

Service load capacity and the value of Dead and live loads.

We will find the nominal load due to yielding, which equals the product of gross area by the yield stress. We have ASTM A-592, grade 50, with a yield stress of 50 ksi and an ultimate stress of 65 ksi.

The nominal load for yielding will be (4.75* 50)=237.50 kips, and the LRFD value will be (0.9* 237.50)=213.75 kips.

The nominal load due to rupture equals the product of the effective area by the ultimate stress. The nominal load for rupture will be equal to (3.673*65)=238.76 kips, and the LRFD value is equal to (0.75*238.76)=179 kips.

The minimum LRFD value is 179 kips, which is the service load capacity.

We shall equate the ultimate load. Because the live load is three times the dead load, we can calculate that the dead load is 29.80 kips and the live load is 89.40 kips.

The PDF file for this post can be viewed or downloaded from the following link.

The next post is post #10, about the Introduction to block shear.

For a more detailed illustration of block shear, there is a very useful external link to the Tension Members chapter 3. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Chapter 3 – Tension Members– A Beginner’s Guide to Structural Engineering is a great external resource.A Beginner’s Guide to the Steel Construction Manual, 15th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 16th ed.