Introduction To Block Shear Resistance.

This is the content of the lecture.

Slenderness ratio as recommended by Aisc.

The first part includes the recommendation of the slenderness ratio L/r from the code that is preferred to be =300 due to handling and controlling vibration effects.

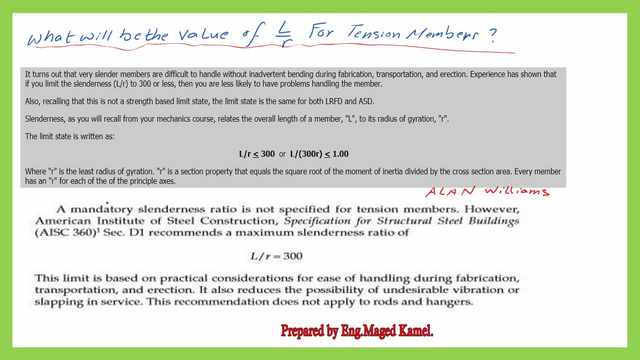

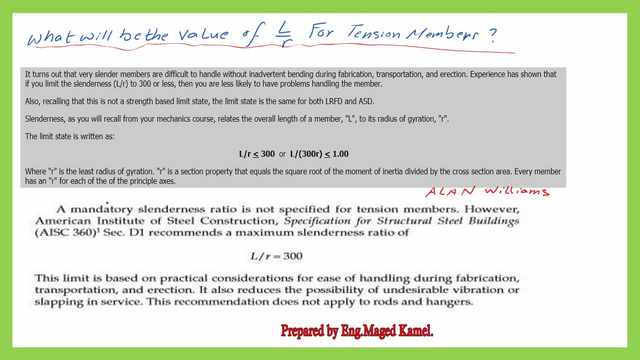

For very slender sections, there is a problem with the handling of these sections, the main requirement while handling is to make handling without inadvertent bending.

While lifting a slender section by crane, it might buckle or be distorted due to transportation and erection, experience has shown that if you limit the slenderness L/r to 300.

You are less likely to have problems handling the member with the experience if we deal with a slenderness ratio L/r at a value of 300.

The problems that will occur during handling can be minimized, there is not a strength limit state, the limit state is the same for both LRFD and ASD, L/r is not related to LRFD or ASD parameters

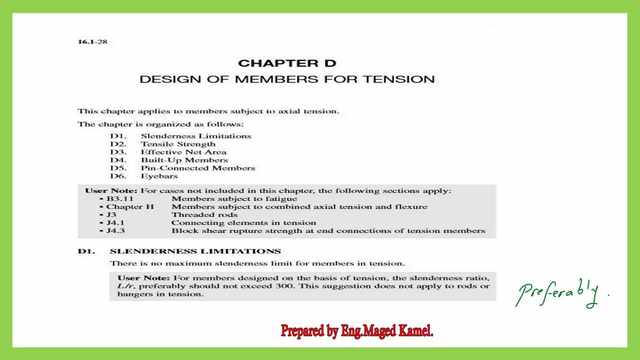

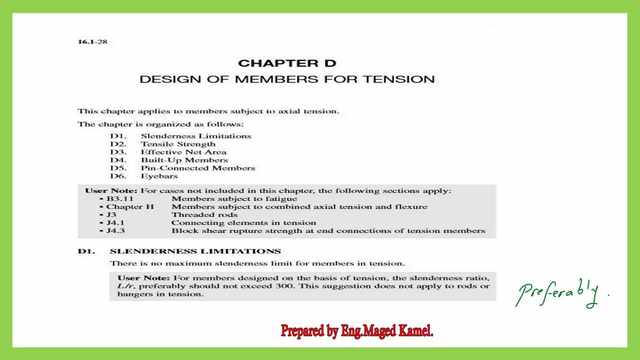

The recommendation in code is in chapter D. Design of Members for tension, specification 16.1- page 28, AISC 360 In chapter D1 for members designed based on tension. The slenderness ratio L/r preferably should not exceed 300, This suggestion does not apply to rods or hangers in tension.

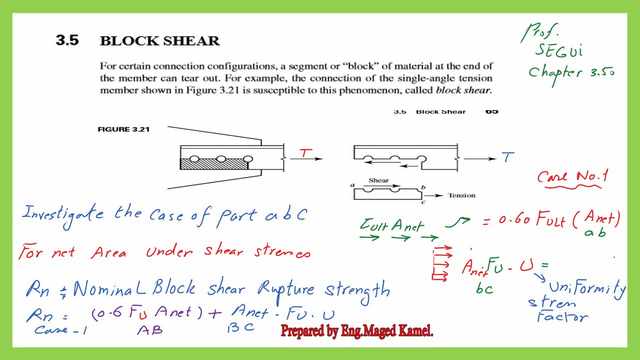

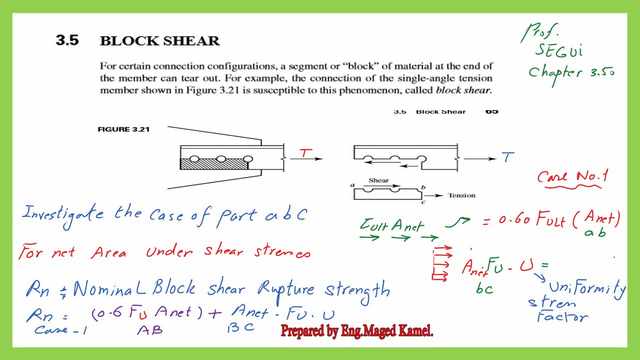

How do we derive the equation for b-shear for tension members?

If bolts join two pieces, they are subjected to two equal and opposing tensile forces.

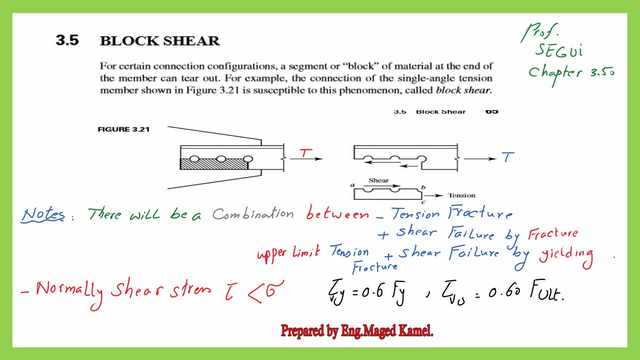

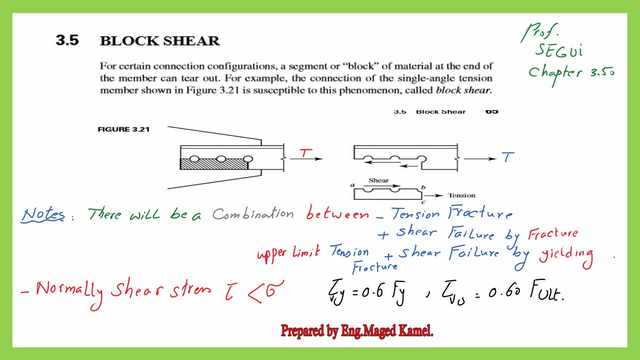

After studying one section, we will discover that the tensile force may be divided into two components: one component is perpendicular to part bc, as shown in the illustration. In contrast, the other component generates shear in part ab. There will be two types of fracture: yielding and rupture for both tension and shear stresses.

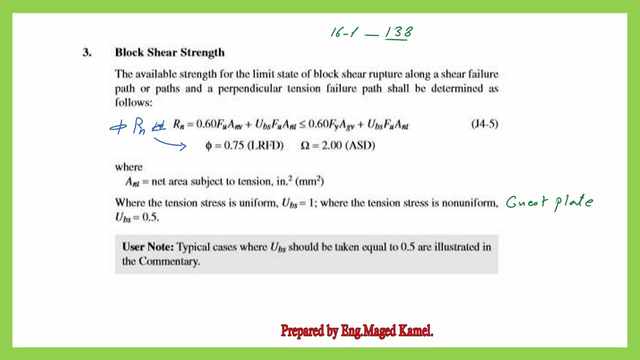

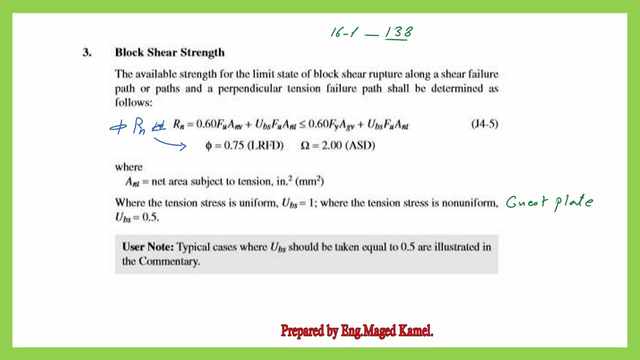

Block shear Formula.

This is the nominal value Rn calculated using the formula, which has two parts: one for shear and one for tension. Area Agv is the gross area with a shear component, and we do not deduct the bolt area. Ant is the net area with a tensile component, from which we deduct the bolt area.

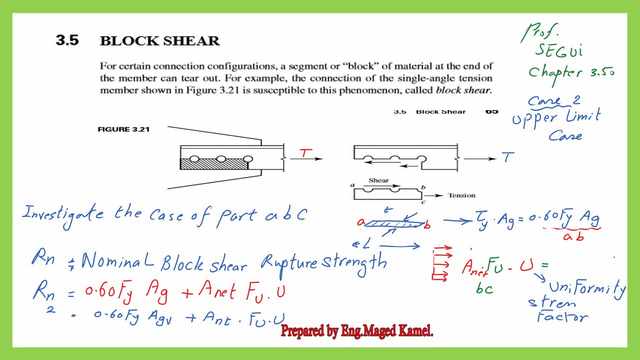

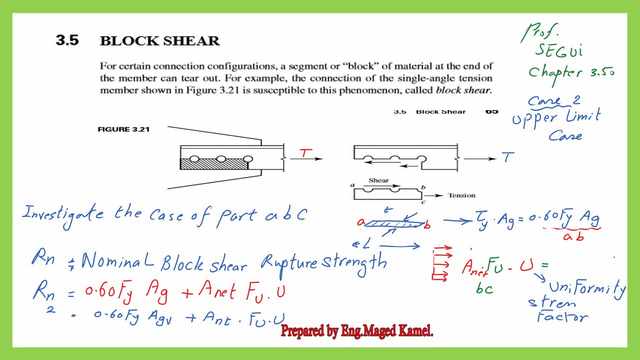

The difference between the upper limit and lower limit.

The difference between the upper limit of fracture, and the other limit of failure, will be considered as follows, the upper limit of fracture, has a combination of Tension failure by rupture and shear failure by yielding.

UBS values vary based on the uniformity of stress distribution for angles & guest plates. Case 1 which is the case that tension stress is uniform. The second case is the case where Ubs=0.50 for nonuniform stress distribution. The UBS values are shown in the next slide image.

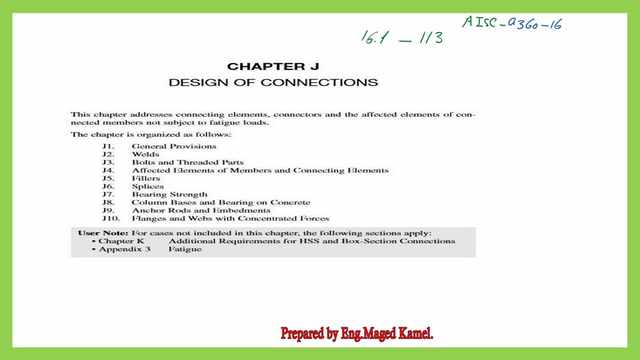

The next slide is the reference in the specs for the chapter relating to the connections which is Chapter J. The provision of steel connections in the specification.

In the next slide, the equation for the block shear strength is J4.5.

This is the PDF file used in the illustration of this post.

There is a very useful external link-Block Shear Rupture–

The next post is a Solved problem 4-4, How to get Pult without block shear.