Last Updated on February 9, 2026 by Maged kamel

How to estimate the nominal and design strength of a bolted plate under tension force?

Solved problem 3-1 for nominal strength.

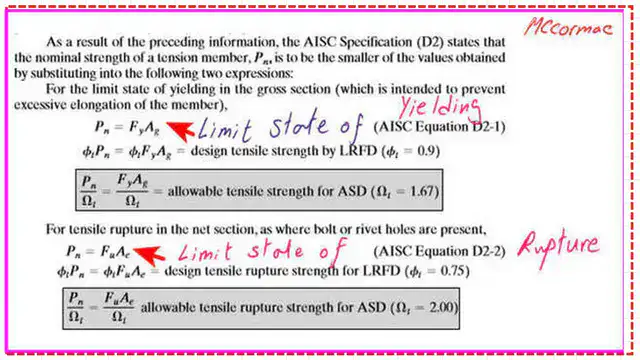

Brief description of the tensile strength and yielding formulas for tension members.

The next slide contains the same known information used as a reference for tensile yielding: the parameter φt = 0.90, to be multiplied by Pn. So, φt * Pn=φt*fy*Ag=0.90 Fy*Ag was for the LRFD nominal tensile strength.

For ASD, use the equation Pn/Ωt = Ag*Fy/Ωt.

When dealing with the net area, we can estimate it using the vertical section or the zigzag line. The selected net area is the smaller of the net areas considered for all possible sections, nominal load Pn = fult*Aeff.

Where Ae=Anet. when U=1 as in the case of the plate. Our φt will be reduced will be=0.75*φt*Pn= φt*Fult*Aeff, LRFD. While for ASD, Pn/Ωt = fult*Aeff /Ωt, where Ωt=2.0. These are the equations used to limit the states of yielding and rupture.

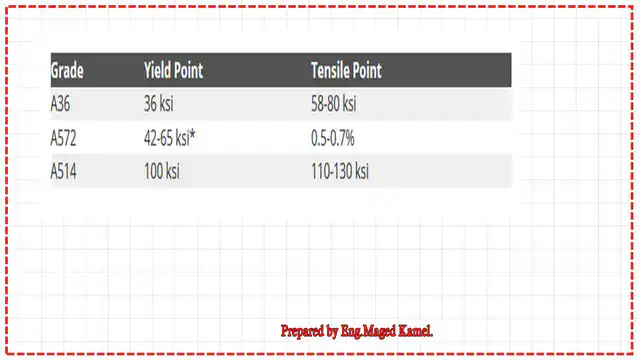

These are the corresponding yield and tensile stresses for different types of ASTM standards.

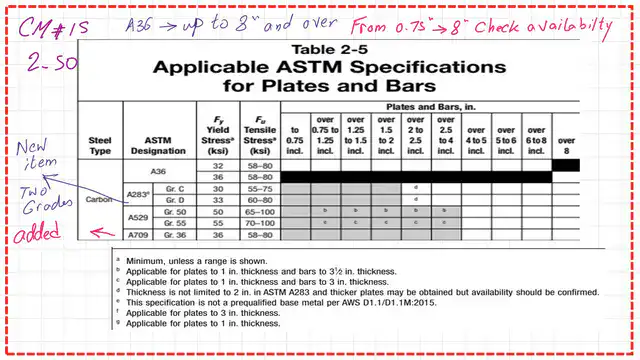

This is Table 2-5, which lists the applicable ASTM specifications for plates and bars.

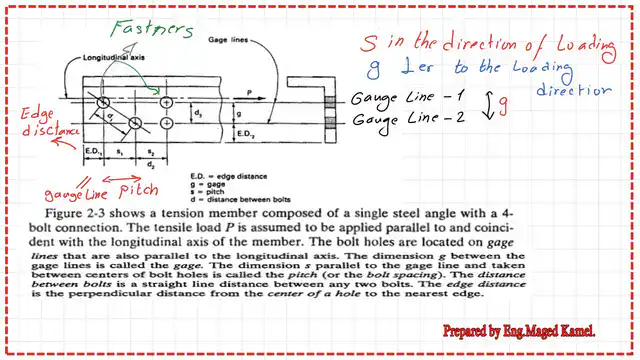

This explains the definitions of the pitch distance S and g, the gauge line distance.

A solved problem 3-1.

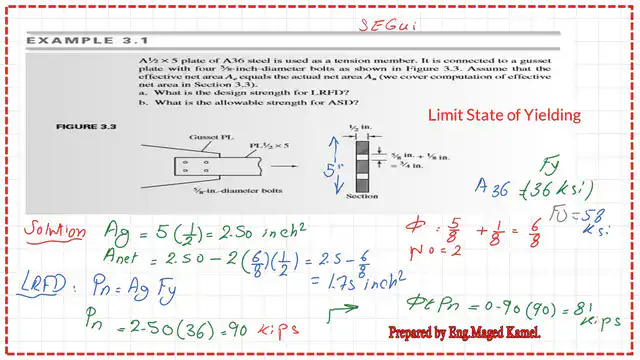

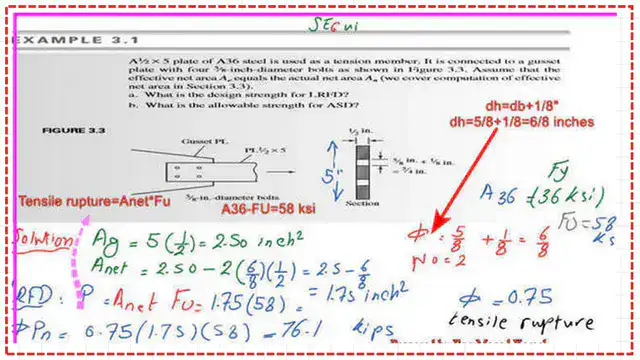

This is the solved problem 3-1; we have a plate of 1/2 inch and a width of 5 inches, made of A36, which is used as a tension member, as part of a truss, for example, as a bottom chord subjected to a tension force. It is connected to a gusset plate with four 5/8-inch fasteners, as shown in Fig. 3-3.

Assume that the effective net area-Aeff = the actual Anet, and the computation of the effective net area will be dealt with later.

It is required to find the following:

1- What is the design strength of LRFD?

2- What is the allowable strength for ASD?

LRFD calculation for design strength.

The steps for the solution of the problem 3-1 are as follows:

1-Check the value Fy, whether 36 ksi or less, we will check Table 2-5, for plates, the width of the plate does not exceed 8″, so it is preferred to consider Fy as =36 ksi and fult=58.0 ksi.

2- Estimate the gross area, we have a width=5″ and thickness of 1/2″ Gross area= Ag=5*1/2=2.50 inch2.

3- Add 1/8″ to the bolt diameter to account for punching and damage, so the diameter of the hole=5/8+1/8=6/8″.

4- for Anet calculation, it is =Agross-sum(d)*t=2.50-2*(6/8*1/2)=1.75 inch2.

5-For failure due to yielding, we can estimate the Nominal tensile strength=AgFy=2.536=90.0 kips. 6-LRFD tensile strength as φtAgfy = 0.902.5036= 81.0 kips, strength due to yielding.

6- The tensile strength due to rupture=AnFult=1.7558=101.50 kips.

7-LRFD tensile strength as φtAgfy = 0.75*101.5=76.125 kips, strength due to rupture.

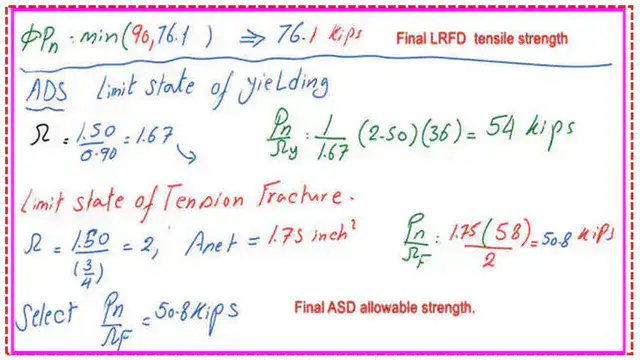

8- select the minimum value for the final LRFD value= min(90,76)=76.0 kips, this value will be the strength design.

ASD calculation for design strength.

Two cases to be considered. The first one is a failure due to yield, with Ωt = 1.67. The second case failure is due to a fracture where Ωt=2.00.

Always φt*Ωt=1.50.

First case failure due to yielding.

We can estimate the ASD tensile strength as (1/ωt)*Ag*fy = (1/1.67)*2.50*36 = 60 kips for yielding.

First case failure due to yielding.

We can estimate the ASD tensile strength as (1/Ω)t*An*fult = (1/2)*(1.75)*58= 50.80 kips for rupture.

For the minimum value of ASD, we will take the minimum of (60, 50.80) = 50.80 kips, which is the final solution for problem 3-1. The allowable service load is the smaller of the two values.

The next post is post 4- Workable Gauge Lines distances for an angle.

The PDF file for this post can be viewed or downloaded from the following link.

For a more detailed illustration of block shear, there is a very useful external link to the Tension Members chapter 3. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Chapter 3 – Tension Members– A Beginner’s Guide to Structural Engineering is a great external resource.A Beginner’s Guide to the Steel Construction Manual, 15th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 16th ed.