Last Updated on January 26, 2026 by Maged kamel

- Case 2 for the block Shear-Coped Beam Problem.

- What are the gross sections for the given beam?

- The value of shear yielding.

- Gross and net area for tension-UBs=1/2 and tension rupture.

- Estimate the shear rupture and tension rupture.

- Estimate the LRFD value of the block shear force, Case 2, for the block Shear-Coped Beam Problem.

- Estimate the ASD value of the block shear force, Case 2, for the block Shear-Coped Beam Problem.

Case 2 for the block Shear-Coped Beam Problem.

In this post, I will include a solved problem for Case 2 for block Shear-Coped Beam problem where the UBS=1/2. The solved problem number #10.8 from the Unified Design of Steel Handbook.

It is required to determine the resistance to block shear of the coped beam W16x40, grade A992, which is the same coped beam from the first solved problem in the previous post, but with a different steel grade, ASTM A992.

The horizontal distance between the beam edge and the centre line of the first line of bolts is 1.25 inches, and the vertical distance between the edge of the beam and the first line of bolts is 2 inches. While the vertical spacing between bolts is 3 inches.

There are two vertical lines of bolts; the horizontal edge distance to the first line of bolts is 1 1/4″. The horizontal spacing between bolt lines is 3 inches. Please refer to the next slide image for more details. The bolt diameter is 5/8 inches. Because we have more than one line of bolts, this is case 2, where the UBS value is 1/2.

What are the gross sections for the given beam?

For W16x40, the web width is 0.305 inches, the flange breadth is 7 inches, and the flange width is 0.505 inches. The yield stress for A992 is 50 ksi, while the ultimate stress is 65 ksi.

For the hole diameter, we add 1/8 inch to the bolt diameter, so the hole diameter is 6/8 inches.

2-There is one section that is subjected to shear, and that is the vertical section through bolts. There is also one section under tension, and that is the lower section.

The value of shear yielding.

3-We estimate the gross area for the vertical section subjected to shear, which can be found equal to (11×0.305)=3.355 inch2. We can estimate the shear yielding value, which is the product of the gross area by (0.6*Fy), where Fy=50 ksi. The shear-yielding value is equal to 100.65 kips.

Gross and net area for tension-UBs=1/2 and tension rupture.

4-We estimate the gross area for the horizontal section subjected to tension, which can be found equal to (4.25×0.305)=1.296 inch2.

To get the net area for tension or Ant, we deduct the area of one and a half bolt holes; the net area Ant equals 0.9531 inch2. This is case 2 for the block Shear-Coped Beam Problem. For the tension rupture force multiply (ubs*Ant*Fu), which is (1/2*0.9351*65)=30.976 kips.

Estimate the shear rupture and tension rupture.

We can get the value of shear yielding and tension rupture. To estimate the shear rupture, we need to find the net area for shear, which is the gross area for shear minus (3.5 holes area). The bolt hole diameter is 6/8 inches, the web thickness is 0.305 inches, and the height is 11 inches. The net area for shear is 2.554 in². Multiply by (0.6*Fy) to get the shear rupture force value, which is 99.60 kips. For the tension rupture, we estimated earlier as equal to 30.976 kips.

Estimate the LRFD value of the block shear force, Case 2, for the block Shear-Coped Beam Problem.

We list all the data which we have obtained we group into two groups. The first group is shear yielding and tension rupture. The second group will be the Shear rupture and tension rupture. We can find that the failure is controlled by shear rupture and tension rupture since their sum is less than the shear yielding and tension rupture.

We select the minimum 130.576 kips, we multiply by phi which is equal to 0.75 we get the LRFD value which is 98 kips, please refer to the next slide image for more details.

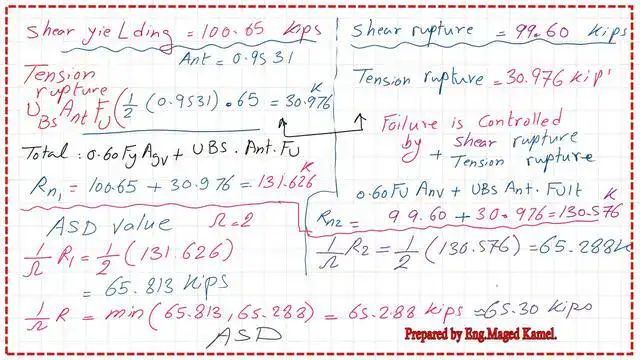

Estimate the ASD value of the block shear force, Case 2, for the block Shear-Coped Beam Problem.

We list all the data we have obtained and group them into two groups. The first group is shear yielding and tension rupture. The second group will be the Shear rupture and tension rupture. We can find that the failure is controlled by shear rupture and tension rupture since their sum is less than the shear yielding and tension rupture.

We select the minimum 130.576 kips, we divide by omega which is equal to 2 we get the ASD value which is 65.30 kips, please refer to the next slide image for more details.

I have reached the end of Case 2 for the block Shear-Coped Beam Problem. Thanks a lot.

The PDF file for this post can be viewed or downloaded from the following Document.

For more details on block shear, please refer to the post “Quickstart to the introduction to block shear resistance.”

For an introduction to coped beams, please refer to the previous posts, post 13-The relation between Block shear and coped beams.

Post-19-Solutions for Block Shear-Coped Beam Problem.

Post-20-Aisc Tables 9-3a,b, and C for Block shear-coped beam.

For a more detailed illustration of block shear, there is a very useful external link- Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 14th ed.