Last Updated on February 20, 2026 by Maged kamel

How to make an analysis of steel beams? Solved problems.

The difference between the analysis and design of a steel beam.

The difference between analysis and design problems is that in analysis, the section is given and a stress check is needed, whereas in design, the loads are provided and the section must be found.

Analysis of the steel beam at zone-1.

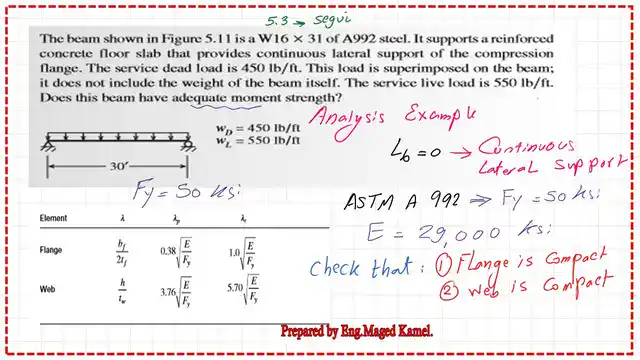

The solved example is 5-3 from Prof. Segui’s handbook. The beam shown in Figure 5.11 is W16x31 of A992 steel, for which 16″is the overall height or nominal depth, while 31 is the weight in lbs per linear ft of A992 steel, where Fy=50 ksi. It supports a reinforced concrete floor slab that provides continuous lateral support of the compression flange.

Here, the compression flange is described as continuously supported, indicating we are dealing with a plastic range or zone -1.

Our λ lies between 0 and λp, and Mn = Mp = Fy*Zx.

The beam shown in Figure 5.11 is W16x31 of A992 steel. W16x31, 16″ is the overall height, while 31 is the weight in lbs per linear ft of A992 steel, where Fy=50 ksi.

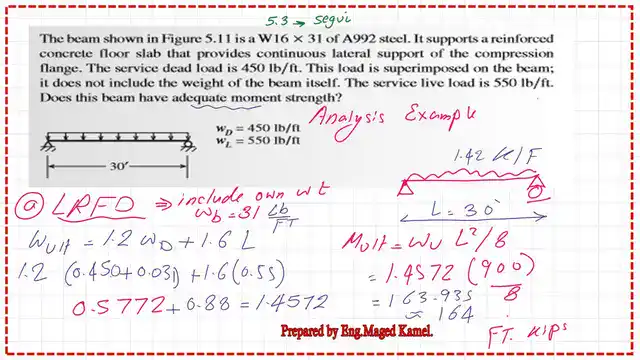

How do we estimate the Ultimate load and Ultimate Moment?

The weight of the beam, which equals 31 lb/ft, is added to the given uniform dead load; The ultimate load equals 1.2*Wd+1.6*wl=1.2*(0.45+0.031)+1.6*(0.55)=1.4572 k/Ft. We estimate the ultimate moment as equal to Wu*L^2/8.The span length equals 30 feet. The final value of the Ultimate moment equals 164 Ft.kips.Please refer to the Next slide image.

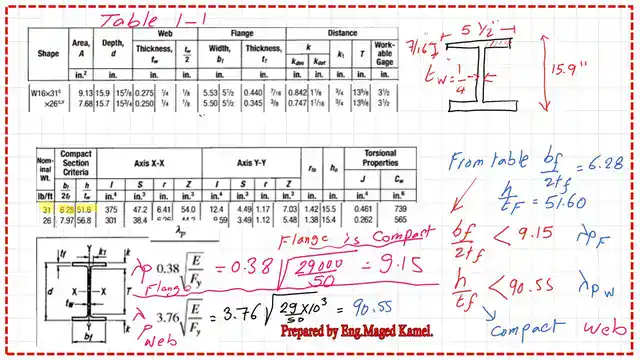

How to check the compactness of the flange and the web of a beam?

We use Table 1 as the first step in analyzing the steel beam. For W16x31 A=9.13 inch2, the overall depth=15.90 inch, the web thickness =0.275 inches, bf =5.53 inch.

The thickness of the t-flange is 7/16 inch.

The controlling factor for the web is 3.76*sqrt(E/Fy), equaling 90.55. The λF, which is 6.28 for the flange, is < λp, which is 9.15; therefore, the section will be in the compact zone for the flange, while λw, which is 51.60, is also < 90.55. The section will be in the compact zone for the web, the first zone.

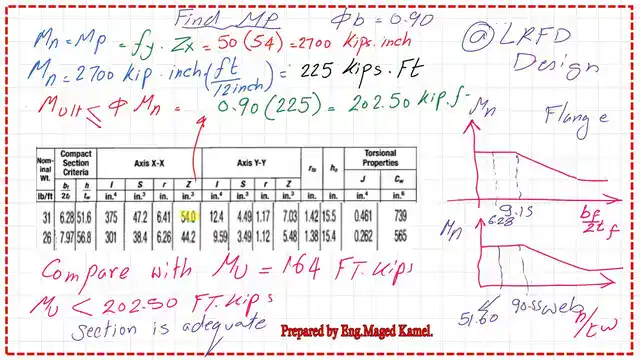

The first step in the steel beam analysis is to obtain the nominal moment Mn = Mp = Fy*Zx. From Table 1-1, we can obtain the Zx value: Zx = 54.0 in³.

To get the Mn=Mp=50*54=2700 inch kips. To convert to ft-kips, we will divide by 12.

LRFD Design-Beam Moment capacity.

Mp=225.0 kips ft. For LRFD, our phi is Φb = 0.90; then Φb*Mn = 0.90*225.0 = 202.50 ft. Kips.

The Ultimate moment, acting on the section, should be <= Φb*Mn.

As estimated earlier, the section can carry 202.50 Ft.kips. This section is adequate for analyzing the steel beam for the LRFD design. This is the end of the analysis of the steel beam.

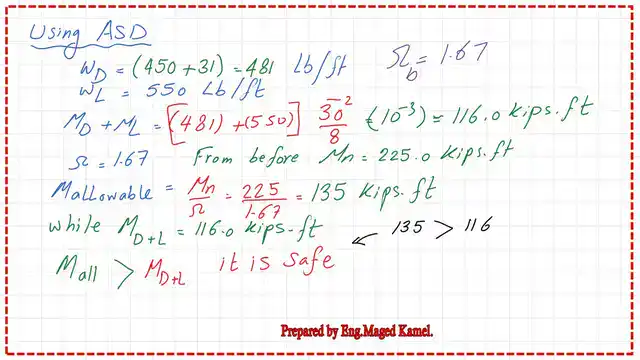

ASD design.

For the ASD Design, Wd = uniform load + own weight = 450 + 31, Wd = 481 lb/ft, and WL = 550 lb/ft. Adding these together for Wt, Mt = (480 + 550) *30^2/8/1000 = 116.0 ft-kips.

This is the total Moment. For Mn =225.0 ft. kips, divide by the omega Ωb, 1.67. M all =225/1.67=1350.0 ft.kips. The section can carry 135.0 ft-kips and is only subjected to 116.0 ft-kips; it is safe.

This section is adequate for analyzing steel beamsfor the ASD design. The idea of the example is that the section of the beam carries a slab with studs to provide continuous bracing; then a section was selected: Bf/2tf, λF was < λp for the flange, and λw was < λp for the web.

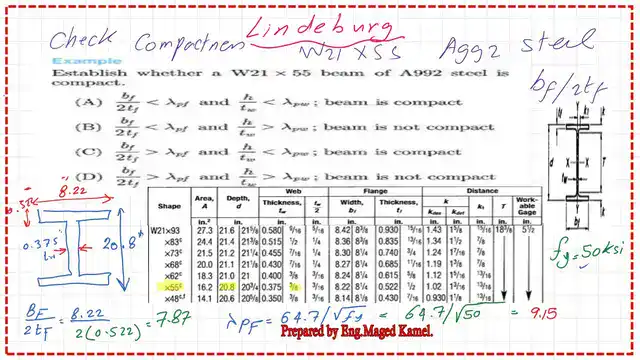

A second problem is to check the compactness of a given section.

This is an example from Lindeburg. Establish whether a W21x55 beam of A992 steel is compact or non-compact. An analysis of steel beams is required.

There are four options. First is the A992 steel with Fy = 50 ksi.

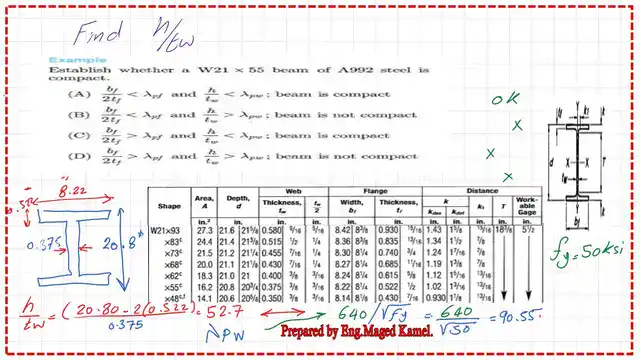

For W21x55, the overall depth is 20.80″, which is highlighted. The web has a Thickness of 3/8″ or 0.375″ t-web. I draw the section, Bf=8.22″, and its thickness =0.522″.

To estimate the controlling lambda, first we need to find the value of Tf/2Tf for the flange, which is 8.22/2*0.22=7.87, and λp for the flange is 64.70/sqrt(50)=9.15. Then, λf<λp for the flange.

For the second part, we will correct the web thickness as 0.375″, h, as estimate =(20.80-2*0.522)/0.375, where tweb=0.375. If we divide 20.80-2*0.522 by the calculator, we get hw, hw=19.756″/0.375 = 52.68.

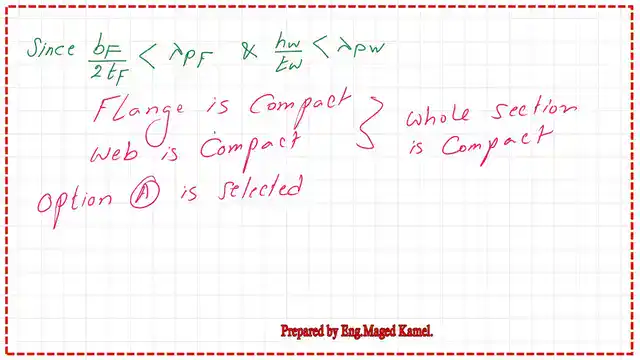

Check against λp, which is 640/sqrt(50)=90.55, then 52.55 is <90.55; since bf/2tf< λp f and hw/tw is< λp t, then option A is correct. This is the end of the analysis of the steel beam. Option A is the proper selection.

The PDF for the data of this post can be reviewed or downloaded.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 16th ed.

For the next post, A Solved problem-4-7-1, how to design a steel beam.