Last Updated on February 14, 2026 by Maged kamel

- Review of AISC Table 2-5 for plates.

- Review of AISC table 2-5 for plates-Construction manual-CM#14.

- A solved problem for ASTM A514 plate-CM#14.

- Review of AISC table 2-5 for plates-Construction manual-CM#15.

- Carbon steel-AISC table 2-5 for plates-CM#15.

- High-strength low-alloy-AISC table 2-5 for plates-CM#15.

- Corrosion-resistant high-strength low alloy-AISC table 2-5 for plates-CM#15.

- Quenched and tempered alloy-AISC Table 2-5 for plates-CM#15.

- Corrosion-resistant and Quenched and tempered low-alloy AISC table 2-5 for plates-CM#15.

- A solved problem for ASTM A514 plate-CM#15.

- Table A 3.1 lists materials based on the new specification 360- 22.

- Table 1-7A-Workable gauges for angles-CM#14.

- Table 1-7A-Workable gauges for angles-CM#15.

- Table 1-7A-Workable gauges for angles-CM#16.

Review of AISC Table 2-5 for plates.

In this post, we will review AISC table 2-5 for plates and explore the differences between the construction manuals CM#14 and CM #15 listed. Later, we will discuss Table 1-7a for both construction manuals CM#14 and CM #15 listed.

Review of AISC table 2-5 for plates-Construction manual-CM#14.

In the next slide, we have AISC Table 2-5, with the heading ‘Applicable ASTM Specifications for Plates and Bars.’

Carbon steel-AISC table 2-5 for plates-CM#14.

According to the construction manual CM#14, there are two groups of carbon steel: ASTM A36 and ASTM A529. The specified Fy for ASTM A36 is available in two grades. The first grade is grade 32, with a yield stress of 32 ksi. Its ultimate stress range is 58 to 80 ksi. This grade is preferred for plates over 8 inches.

The second grade is grade 36, with a yield stress of 36 ksi and an ultimate stress range of 58 to 80 ksi. Grade 36 is preferred for thicknesses ranging from 0.75 to 6 to 8 inches.

ASTM A529 has two grades. The first grade is grade 50, with a yield stress of 50 ksi, and it has an ultimate stress range of 70 to 100 ksi.

The marked “b” with grey color for bars with a thickness above 1 inch.

High-strength low-alloy steel-AISC table 2-5 for plates-CM#14.

We have one category for high-strength low alloys: ASTM A572. It has five grades, with grade 42, for which the yield stress equals 42 ksi, and the ultimate stress, Fu, equals 60 ksi.

The second grade is grade 50, for which the yield stress equals 50 ksi and the ultimate stress Fu equals 65 ksi.

The third grade is grade 55, for which the yield stress equals 55 ksi and the ultimate stress Fu equals 70 ksi.

The fourth grade is grade 60, with a yield stress of 60 ksi and an ultimate stress, Fu, of 75 ksi.

The last grade is grade 65, for which the yield stress is 65 ksi and the ultimate stress Fu is 80 ksi.

Corrosion-resistant high-strength low alloy-AISC table 2-5 for plates-CM#14.

According to CM #14, there are two groups of corrosion-resistant, high-strength, low-alloy steels: ASTM A242 and ASTM A588. ASTM A242 has three values: yield stress, 42, 46, and 50 ksi, and ultimate stress, 63, 67, and 70 ksi.

ASTM A 588 has three values of yield stress, 42, 46, and 50 ksi, and ultimate stress, 63, 67, and 70 ksi.

What is quenched and tempered steel?

Quenching and tempering strengthen materials like steel and other iron-based alloys. These processes heat the material while cooling it in water, oil, forced air, or nitrogen gas.

Quenched and tempered alloy-AISC table 2-5 for plates-CM#14.

We have ASTM A514 c for quenched and tempered alloy, which has two values: yield stress of 90 and 100 ksi and ultimate stress of 100-130 and 110-130 ksi.. The symbol c indicates that it is available only as a plate.

The first yield stress Fy value equals 90 ksi, and the ultimate stress of 100-130 ksi is Gray from over 2.5 to 4.00 inches to over 5 to 6 inches.

The second yield stress, Fy, equals 100 ksi, and the ultimate stress, ranging from 110 to 130 ksi, is marked in Grey from 0.75 to 2.5 inches.

For quenched-and-tempered low-alloy, we have ASTM A825C, which has a yield strength of 70 ksi and an ultimate stress of 90-110 ksi.

A solved problem for ASTM A514 plate-CM#14.

A plate PL3x8 of A514 steel will be used as a tension member in a truss. What values are for the yield stress Fy and ultimate stress Fu to be used in the member’s design?

For CM#14, given the plate thickness of 3 inches according to ASTM A 514, we find that the grey square is available for plates ranging from 2.5 inches to 4 inches, with a yield stress of 90 ksi and a tensile strength of 110-130 ksi. Our Fy will be 90 ksi, and Fu will be 110 ksi.

Review of AISC table 2-5 for plates-Construction manual-CM#15.

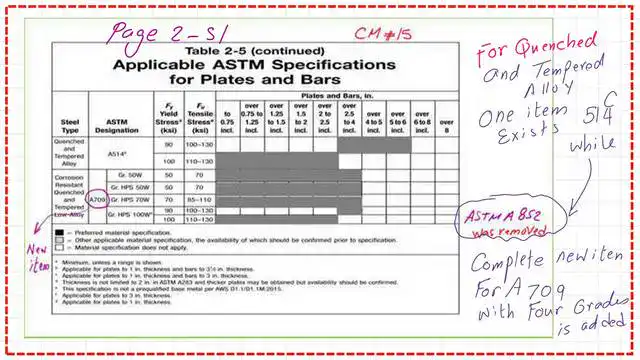

On the next slide, we have AISC table 2-5 for plates, with the heading “Applicable ASTM specifications for plates and bars for CM#15.”

Carbon steel-AISC table 2-5 for plates-CM#15.

For carbon steel, we have four groups: ASTM A36, a new ASTM A283, ASTM A529, and a new ASTM A709. The relevant values for yield stress and ultimate stress are included in the table.

High-strength low-alloy-AISC table 2-5 for plates-CM#15.

We have four categories for high-strength, low-alloy steel. Three additional categories are ASTM A709, Grade 50, and ASTM A1043, which has two grades: Grade 36 and Grade 50.

The third ASTM A1066 has five grades. The relevant values for yield stress and ultimate stress are included in the table.

Corrosion-resistant high-strength low alloy-AISC table 2-5 for plates-CM#15.

According to CM #15, there are two groups of corrosion-resistant, high-strength, low-alloy steels: ASTM A242 and ASTM A588.

Quenched and tempered alloy-AISC Table 2-5 for plates-CM#15.

We have ASTM A514c for quenched-and-tempered alloy steel. It has two yield stress values: the first value is Fy=90 ksi, and the ultimate stress is 100-130 ksi.

The second value is Fy = 100 ksi, and the ultimate stress ranges from 110 to 130 ksi. The symbol C indicates that it is available as a plate only.

ASTM A852c was removed from the quenched-and-tempered alloy in CM #15. We have a new ASTM 709 with four grades: GR. 50W, GR for quenched-and-tempered low-alloy, Hps 50W, GR.HPs 70W and Gr HPS 100W marked e.

Corrosion-resistant and Quenched and tempered low-alloy AISC table 2-5 for plates-CM#15.

A new category, corrosion-resistant and Quenched and Tempered low-alloy, has been added. It has a new ASTM 709 with four grades—GR. 50W, GR. HPS 50W, Gr.HPS 70W and Gr HPS 100W marked e.

A solved problem for ASTM A514 plate-CM#15.

A plate Pl3x8 of A514 steel will be used as a tension member in a truss. What values are the yield stress Fy and ultimate stress Fu for use?

Based on CM#15, for the given plate thickness of 3 inches from ASTM A 514, we find that the grey square is available for plates from 2.5 to 4 inches, but only for a yield stress of 90 ksi and a Fu range of 110-130 ksi. Our Fy will be 90 ksi, and Fu will be 110 ksi. There are no changes between CM#14 and CM #15 for A514 steel.

Refer to Specification 2016 in Chapter General Provisions, Section A3, for the materials section.

Table A 3.1 lists materials based on the new specification 360- 22.

Table A3.1 shows the new specification AISC-360-22 for the used ASTM A. The ASTMA list was tabulated, and the corresponding yield stress in both imperial and metric units was included.

The first table lists the plates with the different ASTMA grades.

The second table lists the plates, bars, and sheets with the different ASTM A grades.

Table 1-7A-Workable gauges for angles-CM#14.

Table 1-7A is for the workable gages in angle legs in inches, if we have an unequal angle, for the short leg. The horizontal distance is shown as g, from the edge to the center to the first fastener line. Table 1-7A includes angles with legs from 1 inch to 8 inches.

For the other, long leg, we have gauge distances g1 and g2. The distances for each leg are shown. Starting from 8 inches descending to 1-inch length, descending to 1-inch length, and g from 5/8 for a 1-inch angle to 4.5 inches, and the values for long leg with two gauge lines for g1 from 3 to 2 inches.

An angle with a 4″ leg can carry only one line of bolts. For a leg angle of 5 inches, it is possible to have two lines of fasteners. Please check the next slide for more details.

Table 1-7A-Workable gauges for angles-CM#15.

Table 1-7A-Workable gauges for angles for tension members based on CM#15 have sizes of legs added that were not included in the previous construction manual, CM#14, for sizes 10 and 8 inches. Gauges g3 and gauge g4 were added, meaning an angle with a 12-inch leg can carry four gauge lines of bolts.

Table 1-7A-Workable gauges for angles-CM#16.

Table 1-7A-Workable gauges for angles for tension members based on CM#16 are the same as Table A71.7A for CM#15. The following slide image shows the details.

The PDF data for this post can be downloaded and reviewed. Please refer to the following PDF document. The PDF contains a copy of Table 2.5 for CM#16.

Post 1C includes data about Table 2-4 and the difference between CM#14 and CM#15

The following post contains solved problems for net area estimation.

See Chapter 3, Tension Members, and Bartlett Quimby for a valid external link.