Last Updated on February 15, 2026 by Maged kamel

The relation between Block shear and coped beams.

Topics included in our discussion are shown in the next slides.

Block shear definition.

We continue discussing the Block shear path graph; the second subject we will discuss is the coped beam and the UBS value condition.

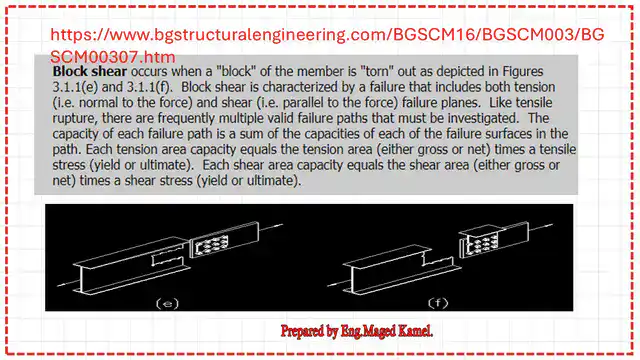

From the site Beginner structural engineering .com / BGSCM16/BGSC. Prof. Thomas Bartlett (Bart) Quimby describes the block shear in the case of the W-section I beam.

There are two modes of failure; the first mode of failure, for which one part was separated, contains the part of the web, plate, and bolts.

The second failure mode involves a T-shaped section consisting of the flange, web, plate, and bolts.

Looking to block shear path no.1, the split section in the middle emerges with the bolts as the tension force acts to the right.

The applied force to the right creates internal forces on the left side: tension and shear.

Because of equilibrium, the tension generated is perpendicular to the left face and acts to the left, whereas the shear force produced is parallel to the force’s direction and acts to the left.

Let us look at block shear path 2. The separated component is in the shape of a T-section, representing the tension force, and its faces are parallel to the force direction. However, the shear force will affect only one face.

Unlike path 1, which has two shear faces, the lower line of bolts is not cut.

The last view is for block shear path no.3, where the cut consists of two lines. The first is vertically up and will create a tension force.

The second line, which passes through the bolts, will have a shear force; the sketch to the right depicts the forces in equilibrium. The side view depicts the T portion.

In the block shear strength equation, the nominal strength is 0.60FultAnv, where Anv is the net area for shear, and Ant is the net area for tension plus Ubs*Fult *Ant = <0.60FyAgv+ UBsFuAnt, which is the upper limit.

Using the LRFD, multiply by φ =0.75. To design using the ASD, divide by Ω = 2.00. The commentary contains two conditions: the first is for Ubs=1, and the second for Ubs=0.50.

What are the Coped beams?

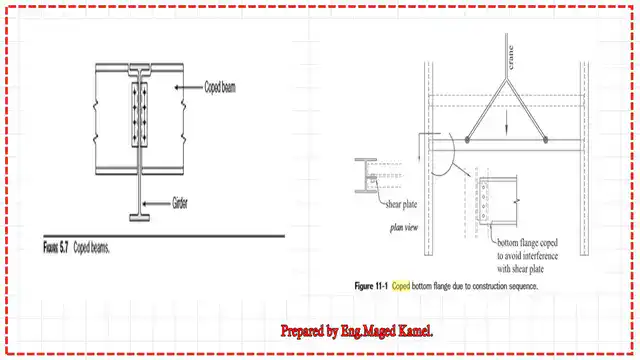

As illustrated in the sketch, the coped beam is a cut in the secondary beam, which is carried by the main beam.

For the two beams carried by the main beam, cuts are made in the flanges on the right and left of the secondary beams, and the connection is made using angles bolted to the main beam’s web.

In the second sketch from the right, the beam must be put between two columns using a crane. The cross-section includes both the column and the lateral coped beam.

We can see a shear plate. The bottom flange is designed to avoid interference with a shear plate. A cut is made to the bottom flange to facilitate crane handling of the beam.

On the next slide, in some cases, field conditions may require a cope; for example, Figure 11-1 shows a beam framing into the column web.

When erecting this beam to its final position, it is dropped down between the Column flanges.

This particular Beam would require a coped bottom flange to be placed without obstruction, so the bottom flange is cut.

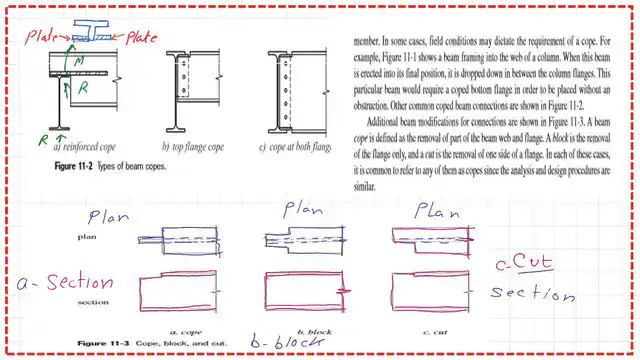

Other common coped beam connections are shown in Figure 11-2. In the first figure, a secondary beam rests on the main beam, and the reaction develops under load.

The cut is made to support the secondary beam on the top of the main beam flange, so both the web and the flange were cut.

Let us examine the forces that require reinforcement to increase the beam’s bending section modulus, Sx.

After cutting the section, it is reduced to a T section, as shown above, so the required reinforcement is provided by two plates on each side of the T-section web.

In the next section, in part b, the top flange cope, where the cut is made in the flange, includes an angle to connect the secondary beam to the main beam; the cut is made only in the top flange.

In the next sketch, part c, the cut is made for the upper and lower flanges of the secondary beam, and both flanges are coped. The beam section is large due to the reaction, so many bolts will be required.

The code specifies different shapes by name.

A beam cope is the portion of the beam web and flange removed; here, a cut is made in both the flange and the web.

In the second section, the name block is given because only a small portion of the flange was removed, so the web was not cut.

A cut is the removal of a side of the flange. All shapes can be considered as coped beams.

Cases where UBS=1

According to the AISC commentary, these are the cases for UBS value = 1.

The new case involves tension and shear due to the reaction that pushes, creating shear stress in the group of bolts oriented vertically.

Tension develops in the tensile area, and the shear area near the edge has a uniform stress distribution.

The second sketch is for the hanger connected to the gusset plate. Here, there is a diagonal member in a truss. The member is under tension, so one face has shear stress, another has shear stress, and the remaining faces have Tension stress.

The other section is for the same connection: an inclined member welded to a gusset plate.

The last case is the coped beam, which is welded. This sketch applies to single-row beam end conditions and to angle ends under tension. Here is a gusset plate.

In all these cases, UBS = 1.

Cases where UBS=0.50

For cases where UBS=0.50 for the coped beam.

In case b, Multiple-Row beam-end conditions, block shear occurs along two lines of bolts, and the tension area has a triangular stress distribution; these stresses are not uniformly distributed.

For part b of the middle section, the web is torn out in a coped beam; because we have only one line of bolts, the stress distribution is uniform.

In the case of C, we have a shear area and a tension area with a non-uniform stress distribution; these cases correspond to UBS = 0.50.

The PDF file for this post can be viewed or downloaded from the following link.

The related posts are included in the steel beams sections.

The next posts are- post 19- Solution for Block Shear-Coped Beam Problem.

The next posts are post 20—Aisc Tables 9-3a,b, and C for the Block shear-coped beam.

The next posts are- post 21- Case 2 for the block Shear-Coped Beam Problem.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 15th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 16th ed.

This is the next post 14: Solved problem 5-7 for block shear.