Last Updated on January 26, 2026 by Maged kamel

AISC Tables 9-3a,b, and C for the Block shear-coped beam.

In this post, we will verify the solution to problem #5.13 in Prof. Alan Williams’s handbook using AISC tables 9-3a, b, and C for the block shear-coped beam.

The solved problem was included in post 19, which required finding the block shear for the coped beam where UBS = 1.00, i.e., a uniform stress distribution for the tension force.

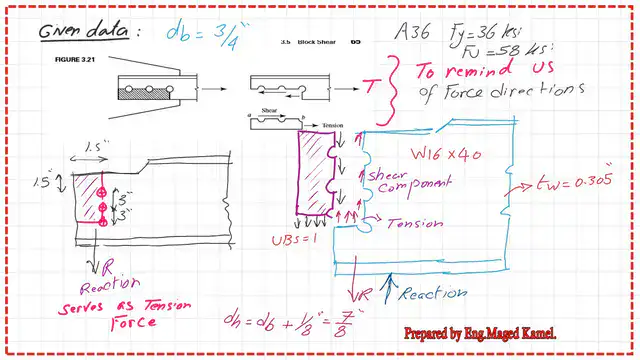

It is required to determine the resistance to block shear of the coped beam W16x40 grade A36.

The horizontal distance between the beam edge and the centre line of the first line of bolts is 1.50 inches, and the vertical distance between the edge of the beam and the first line of bolts is 1.5 inches. The vertical spacing between bolts is 3 inches, as shown in the next slide image. The bolt diameter is 3/4 inches.

This is an elevation section showing the beam, the number and arrangement of bolts, and the vertical and horizontal distances between the edge of the coped beam and the bolts.

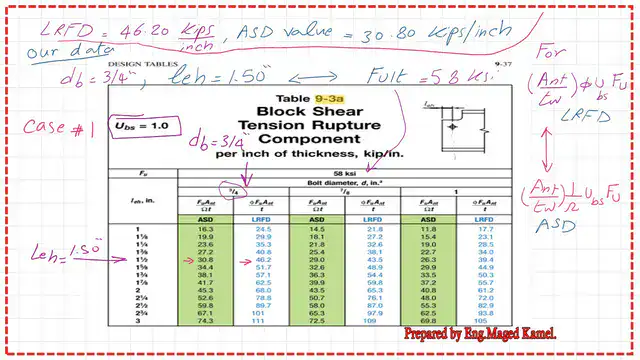

AISC Table 9-3a for tensile rupture for block shear.

We start with AISC Table 9-3a, the first of the three AISC tables used for block shear evaluation.

The coefficient for block shear UBS equals 1. AISC Table 9-3a determines both the LRFD and ASD value for the block shear tension rupture component of the block shear, but the estimated values are for kips per unit inch.

We have Ultimate stress equals 58 ksi. Log in with the first column of Leh values and select the Leh value of 1.50 inches, where Leh is the horizontal distance from the edge to the first line of bolts.

The bolt diameter is 3/4 inches, and the intersection between the horizontal line from Leh equals 1.50″ line, and the two vertical lines from the bolt column of 3/4 inches will give us both the LRFD value and the ASD value for tensile rupture.

As shown, the LRFD value for tensile rupture is 46.20 kips/inch, while the ASD value is 30.80 kips/inch.

AISC Table 9-3b for shear yielding component.

Here is the second of the three AISC tables, Table 9-3b, used to estimate the shear-yielding component of block shear. The yield stress is 36 ksi.

The first column is for Lev, the vertical distance from the edge to the first line of bolts. We also need the S value, which is the spacing between bolts.

Column n specifies the number of bolts; in our example, n equals 3.

The horizontal line from Lev=1.50 inches and n=3 is drawn and intersects with the lines from Fy=36 ksi, which will give the two values for LRFD and ASD of the shear-yielding components for block shear.

As we can see, the LRFD value of the shear-yielding component is 121 kips/inch, while the ASD value for tensile rupture is 81.1 kips/inch.

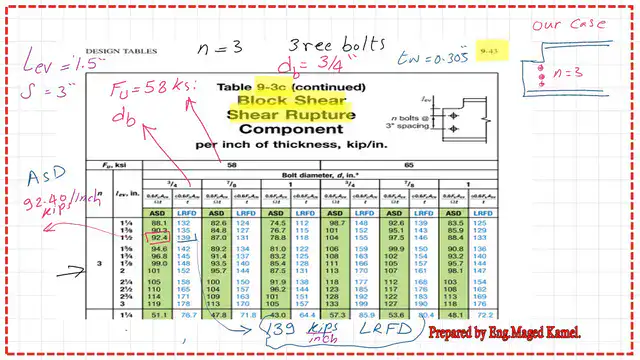

AISC Table 9-3C for shear rupture component.

This is the third AISC table, the last of which is Table 9-3C, used to estimate the shear rupture component of block shear. The ultimate stress is 58/ ksi.

The first column is for n, the number of bolts, which is 3.

The second column is the lev column. We draw a line with n = 3 and lev equal to 1.50 inches. We draw two vertical lines from the bolt column at the point where db = 3/4 inches. We will get two values for LRFD and ASD for the shear rupture component. The LRFD value equals 139 kips /inch, and the ASD value equals 92.40 kips/inch.

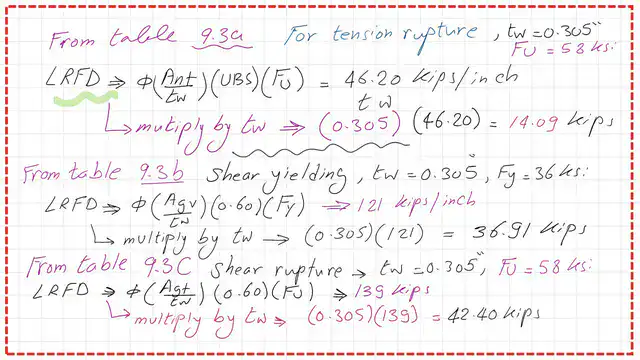

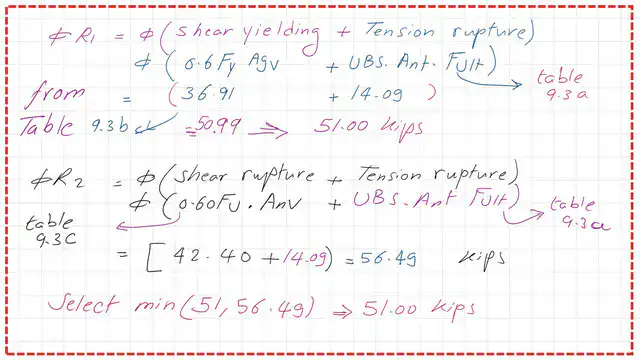

We can see the results for The LRFD values for tension rupture, shear yielding, and shear rupture from AISC tables 9-3a, 9.-3b, and 9-3c. We multiply each value by the web thickness tw, which is 0.305 inches.

We have two values for the LRFD from two cases. The first case is shear yielding and tension rupture, for which the sum of the two values is approximately 51.0 kips.

The second case is shear rupture and tension rupture, for which the sum of the two values is approximately 56.49 kips. We will select the smaller value, which is 51.00 kips.

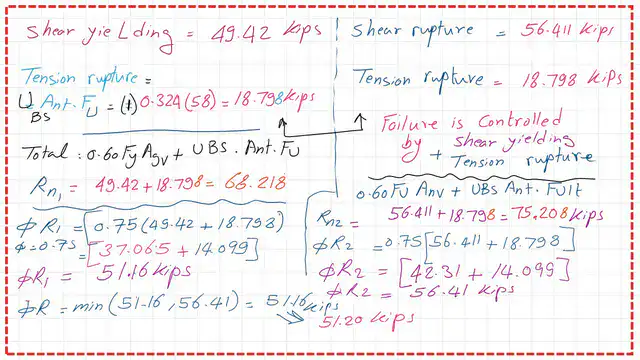

This is a reminder of the previously estimated LRFD value for block shear based on the calculation. Please refer to the previous post for more detailed information. There is a match between this estimation and the LRFD value obtained from tables.

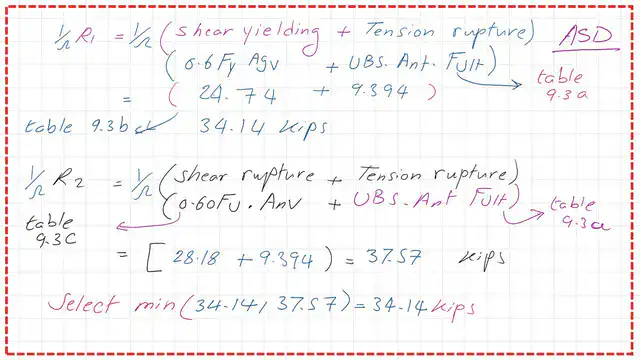

We can see the results for the ASD values for tension rupture, shear yielding, and shear rupture from AISC tables 9-3a, 9.-b, and 9-3c. We multiply each value by the web thickness tw, which is 0.305 inches.

We have two ASD values from two cases. The first case is shear yielding and tension rupture, for which the sum of the two values is approximately 34.14 kips. The second case is shear rupture and tension rupture, for which the sum of the two values is approximately 37.57 kips. We will select the smaller value, which is 34.14 kips.

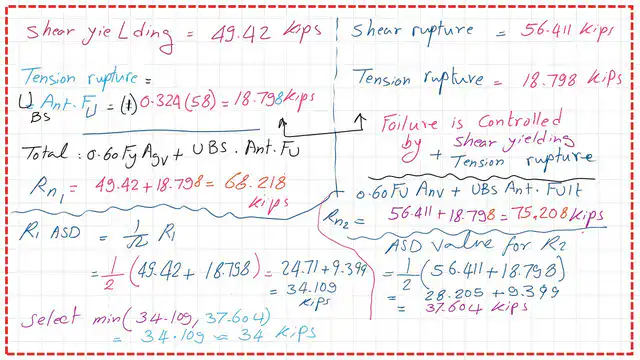

This is a reminder of the previously estimated ASD value for block shear based on the calculation. Please refer to the previous post for more detailed information. There is a match between this estimation and the LRFD value obtained from tables.

The PDF file for this post can be viewed or downloaded from the following Document.

The previous post link: Post-19-Solutions for Block Shear-Coped Beam Problem.

The next post: Post 21-Case 2 for the block Shear-Coped Beam Problem.

For a more detailed illustration of block shear, there is a very useful external link yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 14th ed.