Last Updated on February 8, 2026 by Maged kamel

Problem 3-4-3 for MC section-LRFD and ASD value-2/2.

We are dealing with the second part of problem 3-4-3 for the MC section, LRFD, and ASD value-2/2. We will check the fourth failure line. Decide the least value of the net area. We will estimate the effective area by multiplying it by the factor U, as obtained in case 2.

We can estimate the design strength due to yielding and rupture for the LRFD and ASD designs.

Problem 3-4-3 for MC section-route line-E1-A-d-e-E2.

We will examine the last route and determine the final net area for the different routes.

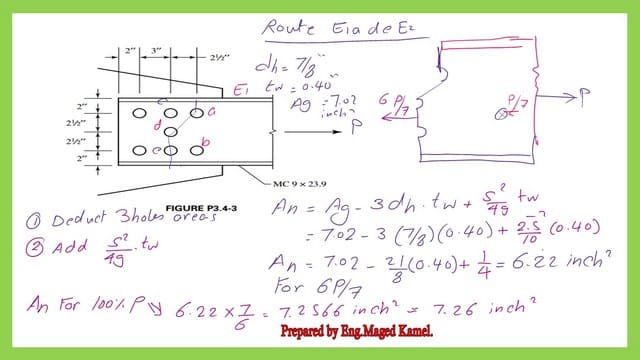

We check the route line E1-A-d-e-E2; please refer to the next image for more details. Each bolt transfers the applied force by a ratio of force value by the bolt’s number, equal to P/7. Again, we will estimate the sum of deductions due to holes and additions due to staggered bolts.

The spacing between bolts s is 2 1/2 inches in the direction of the force P, and the vertical distance, g, is perpendicular to the force P, is 21/2 inches. The gross area is 7.02 inches2.

The whole area can be estimated as the product of the number of bolts by the web thickness by the hole diameter, equal to (3*7/8*0.40)=1.05 inch2.

Due to staggered lines, the added area is s^2*tw/4g, which is (2.5^2*0.40/(4*2.50)) = 0.25 in^2. The net area equals 6.22 inch2.

Section E1-A-d-e-E2 excludes one bolt that transfers P/7 to the Gusset plate. Check the left side of the section; we have 6 bolts. The section is fit for only 6/7P, and the remaining force is due to the sum of forces. The modified area will be (6.22*7/6) = 7.26 in^2.

Problem 3-4-3 for the MC section, the final net area.

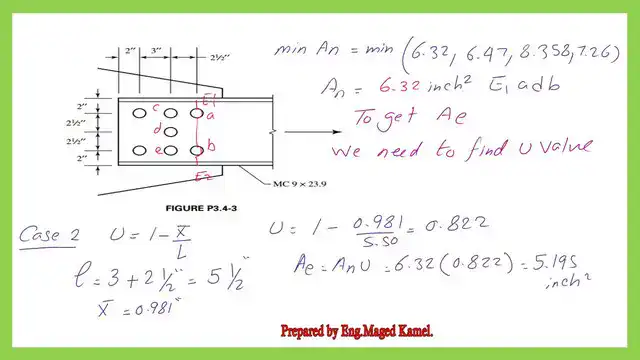

I have listed all the net areas for the 100% p section. The final net area is 6.32 in^2 from E1adb to E2.

The next step is to determine the U value, or the shear lag factor. This is case 2: a tension member is partially connected, and the U value is less than 1. The U value = 1-xbar/L. The x-bar value equals 0.981 inches. The length of the connection equals 5.50 inches.

The U is 0.822. The effective area is the product of U and the net area and equals 5.195 in^2.

How do we find strength for the MC section?-LRFD and ASD values.

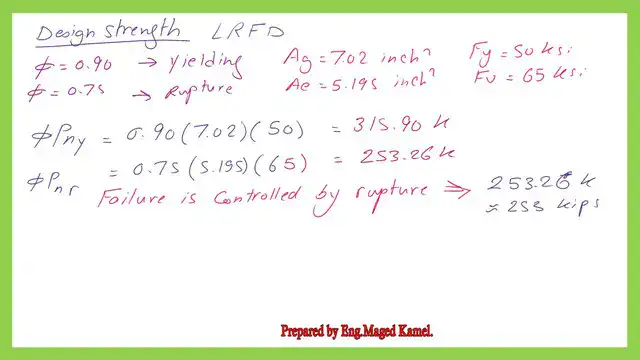

We will estimate the LRFD strength due to yielding and rupture, assuming phi = 0.90 for yielding and 0.75 for rupture. The gross area is 7.02 in^2, and the effective area is 5.195 in^2.

Yielding design strength equals 315.90 kips. The Rupture design strength equals 253.26 kips. Select the min value, which is 253.0 kips.

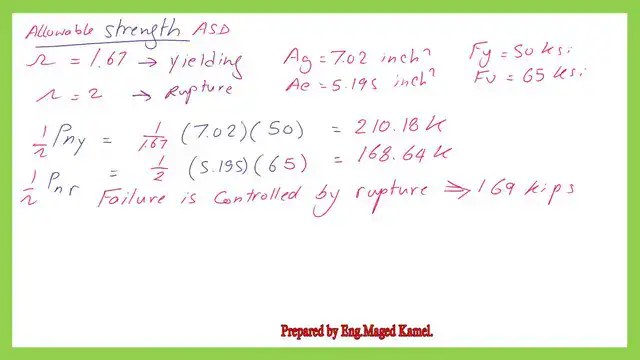

We will estimate the ASD strength due to yielding and rupture, assuming omega values of 1.67 for yielding and 2 for rupture. The gross area is 7.02 in^2, and the effective area is 5.195 in^2.

The yielding design strength is 210 kips, and the rupture design strength is 168.80 kips. Select the minimum value, which is 168.80 kips.

This is the final part of Problem 3-4-3 for the MC section, LRFD, and ASD value. We can get the LRFD and ASD values based on the yielding and rupture conditions.

Thanks a lot, and see you in another post.

Please refer to the first part of this post, Problem 3-4-3 for staggered bolts-tension members-1/2.

The PDF file for this post and the previous one can be viewed or downloaded from the following link.

The next post will include the Effective Area for a Built-Up Section.

For a more detailed illustration of block shear, there is a very useful external link to the Tension Members chapter 3. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 15th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 16th ed.