Last Updated on February 16, 2026 by Maged kamel

Practice problem 5-5-8-Compute Mn for W18x71 with lb=9 feet.

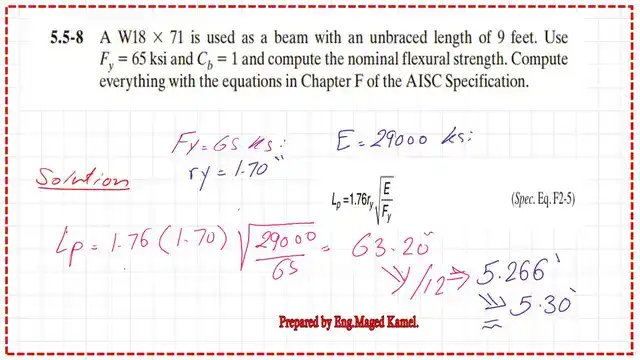

Practice problem 5-5-8 A W18 x 71 is used as a beam with an unbraced length of 9 feet. Use Fy=65 ksi and Cb = 1 and compute the nominal flexural strength. Compute everything with the equations in Chapter F of the AISC Specification. Practice problem 5-5-8 is from the Steel Design Handbook.

How do we estimate Lp for W18x71 with Fy=65 ksi?

In the absence of design aids, Table 3-3, where W sections are sorted by their plastic section modulus Zx and with a different Fy (Fy = 65 ksi), we need to estimate Lp and lr using the equations given in the specifications.

The following slide shows the detailed estimate of the Lp value. Lp is the unbraced length at which the plastic hinge should develop, given by equation F2-5 as 1.76*rysqrt(E/Fy).

From Table 1-1, we will get the radius of gyration, ry, for W18x71. The ry value is 1.70 inches, based on the data that Fy = 65 ksi. The E value is 29000 ksi. The value of Lp is 63.20 inches, which can be rounded to 5.30 feet.

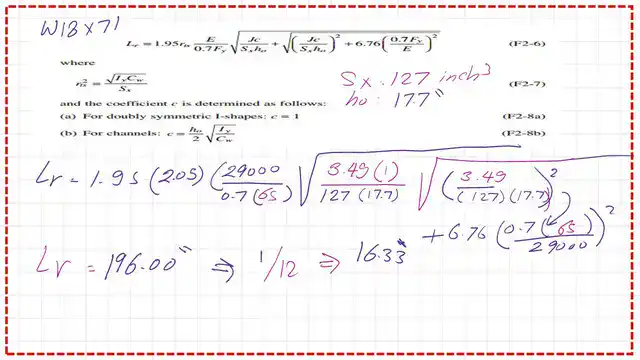

How do we estimate Lr for W18x71 with Fy=65 ksi?

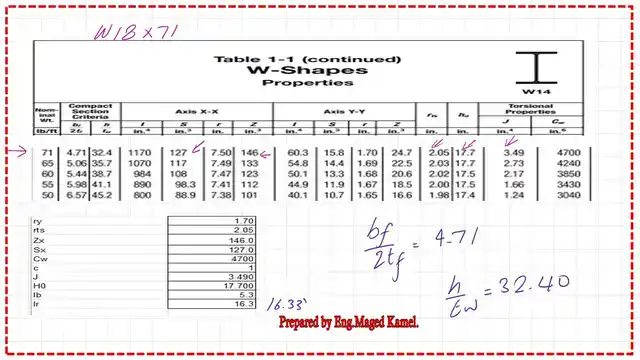

We use Table 1-1 for the W18x71 W section to obtain the data needed to estimate Lr. Lr represents the unbraced length at which lateral-torsional buckling transitions from the inelastic range to the elastic range. These items are: ry, rts, Zx, SX, Cw, C, J, H0. The Sx value equals 127 in^3, while Zx = 146 in^3.

We can get the value of bf/2tf and h/tw. Please refer to the next slide image for details.

What is the value of lr?

We use the equation F2-6 provided by the AISC specification. The value of lr for W18x71 equals 196 inches and is rounded to 16.33 feet. Please refer to the next slide image for more details.

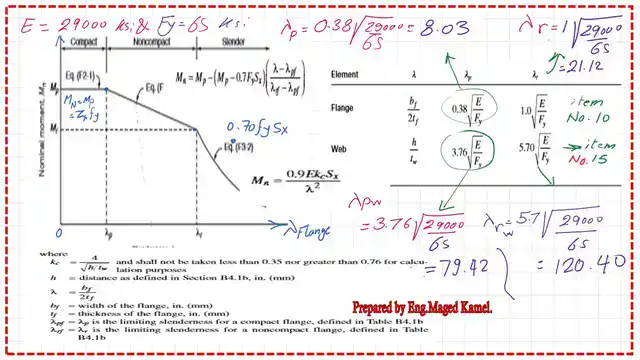

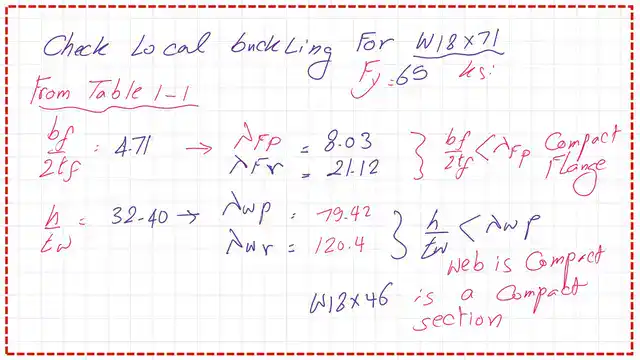

Check the buckling parameters for W18x71 with Fy = 65 ksi.

We will determine the local buckling parameters for the flange and web, with Fy = 65 ksi. Based on item 10 in Table B4.1b, the flange λFp=0.38*sqrt(E/Fy), since we have E29000 ksi and the given Fy=65 ksi, then λFp=0.38*sqrt(29000/65)=8.03. λFr=1.0*sqrt(E/Fy)=1*sqrt(29000/65)=21.12.

For the web compactness ratio, the flange λwp = 3.76*sqrt (E/Fy), and λWp = 3.76*sqrt (29000/65) = 79.42. λwr=5.70*sqrt(E/Fy)=5.70*sqrt(29000/65)=120.4. Please refer to the next slide image for the detailed estimate of compactness ratios.

Check whether W18x71 is compact or non-compact.

On the next slide, we show the bf/2tf and h/tw values of W18x71 against the required local buckling parameters for Fy = 65 ksi. We will find that the flange and web are compact, so the entire W18x71 section is compact.

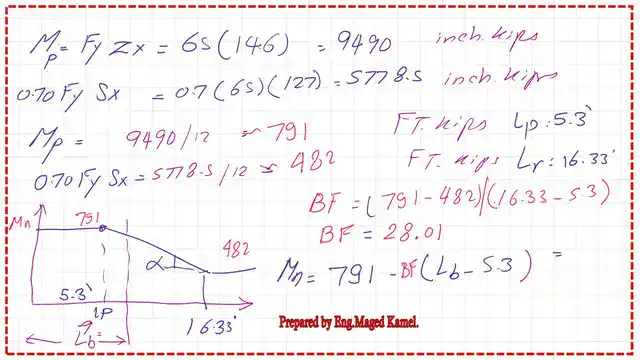

Find the equation of Mn-based on Fy=65 ksi.

The Plastic moment value equals Zx*Fy, which is equal to 65×146 = 9490 inches. Kips. The term (0.7*Fy*Sx) value equals 0.7*65*127=5778.50 Inch. Kips. The first term corresponds to bracing length Lp=5.30 ft; the second corresponds to lr=16.33 feet. We have a given bracing length of lb = 9 ft.

We get the values of Mp and 0.70*Fy Sx in ft·kip using the conversion factor 1 ft = 12 in. Mp value equals 791 ft-kips, while 0.70*Fy Sx = 482. We could round these values to the nearest.

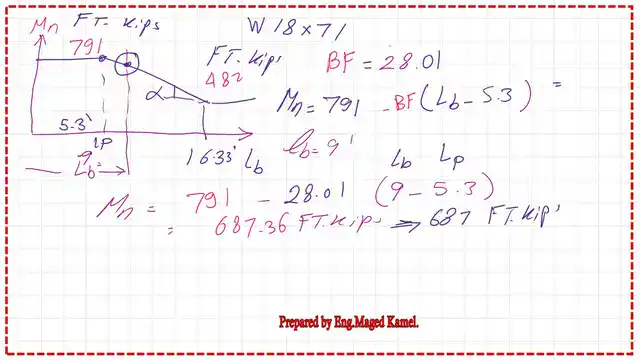

There is a linear relationship among the required Mn and Mp, as well as (0.7*Fy*Sx), and between Lp and Lr. The BF factor is the slope value, which equals (Mp-0.7*Fy*Sx)/(Lr-Lp)=28.01.

What is the value of Mn for W18x71 at lb=9 feet?

The relation of 791-28.01*(Lb-Lp) represents the nominal moment value. The Lb value equals 9 feet, and the Lp value equals 5.30 feet. The Final value for Mn equals 687 Ft. kips.

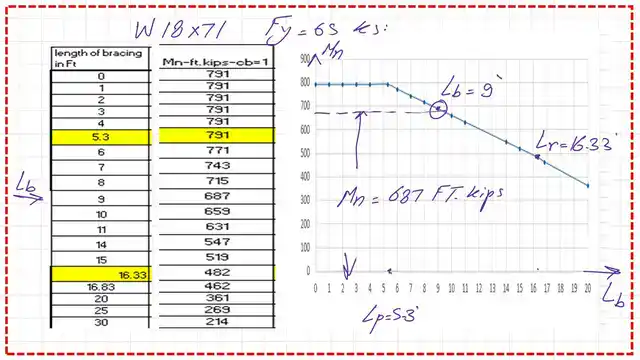

We could use an Excel spreadsheet to plot the relationship between Lb and the Flexural design strength, Mn, in ft·kips, for W18x71 with Fy = 65 ksi. We can see the linear portion, and the Value of Mn at 9 feet is 687 ft-kips. Thanks a lot.

The PDF file for this post can be viewed or downloaded from the following link.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 16th ed.

For other previous posts with practice problems, we have 9b-Practice problem 5-4-1-Check compactness for Fy=60 ksi.

And we have 9c-Practice problem 5-5-6: Compute Lp, Lr, and φb*Mn.

This links to the next post, 10-lateral-torsional buckling for steel beams.

A new post has been added: 41-Practice problem 5-6-1: find the total service load for W12x65. The section is non-compact.