Last Updated on February 17, 2026 by Maged kamel

Solved problem-7-4-1-part 2.

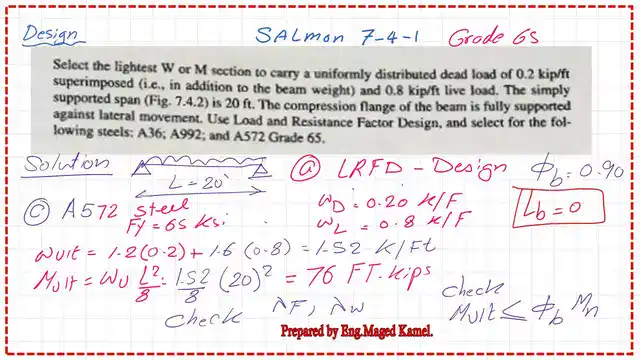

This is the second part of problem 7-4-1, where we are required to design a W-section for a beam with a span of 20 Feet. The steel is A572, with Fy = 65 ksi.

For Case 3, design a steel beam with Fy = 65 ksi. Solve the problem: 7-4-1-part 2.

Find the Ultimate Moment for the given beam.

The following slide shows the value of the ultimate load without considering the beam’s weight; this will be added after selecting the section. The ultimate load is 1.52 kips/ft, and the ultimate moment is 76 ft. kips. The beam’s flange is fully supported against lateral movement.

We will equate the ultimate moment with the φb*Mn or φb*Fy*Zx.the Fy=65 ksi, φb=0.90, Mu=76 Ft.kips.

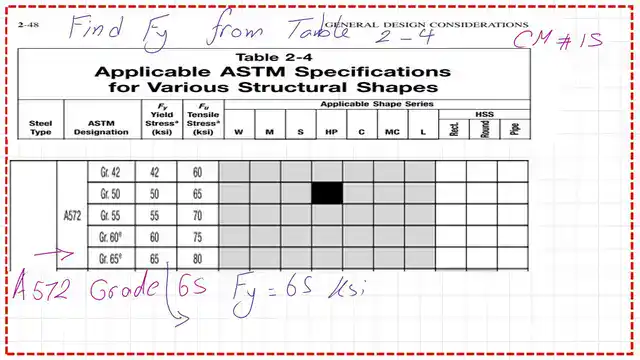

A reminder of Fy for A572 Grade 65 from Table 2-4.

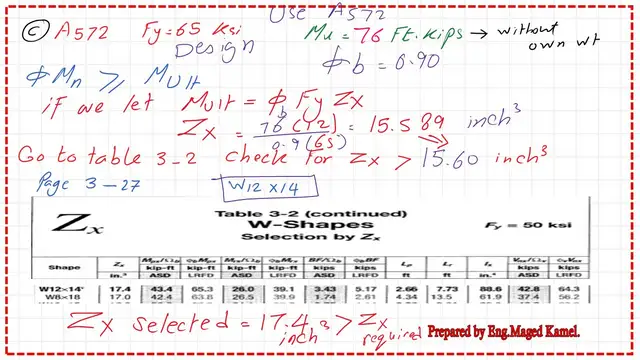

Determine the required Zx-select a section.

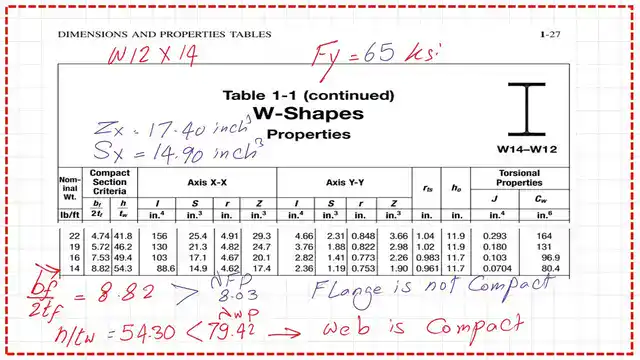

The required Zx value is 15.589 inch3. Using Table 3-2 for W sections sorted by Zx, we will select a W12x14 with a Zx value of 17.40 in^3; Zx selected > Zx required. Please refer to the next slide image for more details.

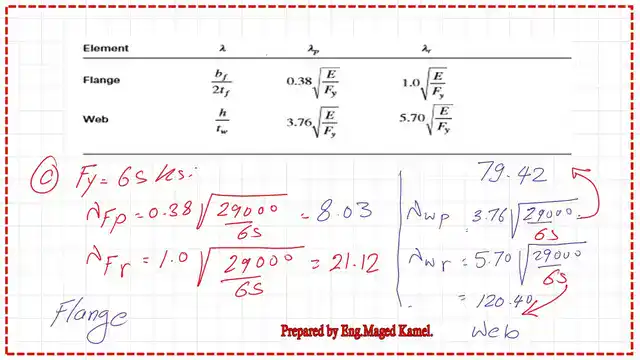

We need to check whether W12x14 meets the local buckling parameter requirements. The next slide shows the controlling parameters for the flange and web.

What are the local buckling parameters based on Fy=65 ksi?

Based on Fy = 65 ksi, the lambda for the flange at the plastic stage is λFp = 8.03. The lambda for flange at elastic stage λFr=21.12. The lambda for web at the plastic stage is λwp = 79.42. The lambda for the flange at the elastic stage λwr=120.40. The next slide shows the detailed estimate and the corresponding values for Flange λ and Web λ, assuming Fy = 65 ksi.

Check flange λ and web λ against local buckling parameters.

In the second part, we use Table 1-1 for W12x14 to find the value bf/2tf, which equals 8.82, while h/tw equals 54.30. If we check, we will find that bf/2tf is greater than λFp but less than λFr, which means the flange is non-compact. For λw < λwp, meaning the web is compact. So the entire W section will be considered as non-compact.

The Nominal Moment for W12x14 is between the value of (Fy*Zx) and (0.7*Fy*Sx). The elastic section modulus Sx=14.90 inch3, while the plastic section modulus Zx equals 17.40 inch3.

Find the Nominal moment of W12x14.

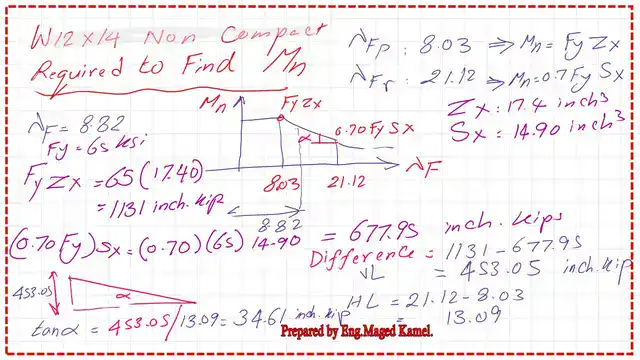

For the next slide, the flange lambda value is λF = 8.82; Fy = 65 ksi.

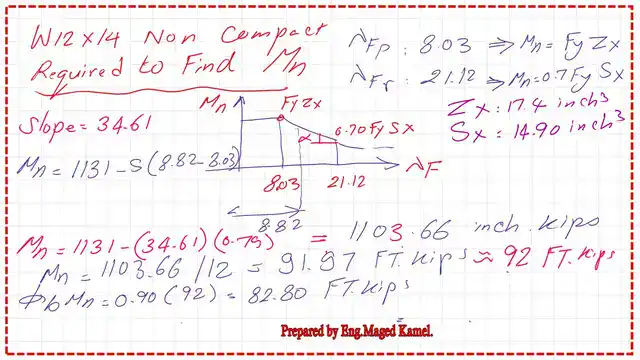

Our λf = 8.80 is between λf-p and λf-r. It is required to get the Mn value.From Equation F3-1, Mn=(Mp-(Mp-0.70Fy*Sx)/(λfr-λfp)). This is the final step in designing a steel beam for Fy = 65 ksi.

Mn is the same as the equation for a straight line y=m*x. We will estimate the Mn for the upper Point, which equals Mp = Fy* Zx = 65* 17.40 = 1131 in. Kips. The second point Mn=0.70*Fy*Sx, Sx for the section=14.90 inch2.

0.70*Fy*Sx=0.70*65*14.90= 677.95 inch. Kips.

What about lateral torsional buckling?

For lateral torsional buckling, the compression flange is fully supported against lateral movement. The section is safe against lateral Torsional buckling. The subject of lateral torsional buckling will be discussed in post 10.

Find the slope of the Linear portion.

We can find the slope of the linear portion, which equals (Fy*Zx-0.70Fy*Sx)/λfr-λfp). The next slide shows the slope’s value as 34.61 inches. Kips.

Now, we can find the Nominal moment equal to Mp-S*(λf-λp)=1103.66 inch. Kips. We can find the value in feet-kips to be 92.0 ft-kips. The Φb value is 0.90. the factored Mn=82.80 Ft.kips.

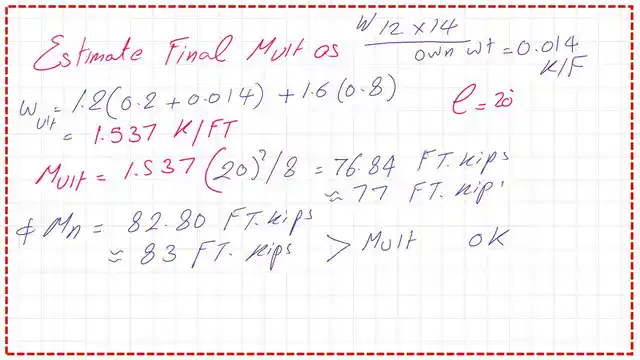

We will finalise the ultimate moment value by adding the weight moment of the W section. The final Mu value is 77.0 feet. KIPS. The Φb*Mn=83.00 feet. Kips. The section is safe since Φb*Mn>Mult. This is the end of the post. Thanks a lot.

For the first part of this post, please refer to post 9: How to design a steel beam? Solved problem-7-4-1.

The PDF file for this post can be viewed or downloaded from the following link.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8: Bending Members. A Beginner’s Guide to the Steel Construction Manual, 16th ed.

This links to the next post, 9b-Practice problem 5-4-1-Check compactness for Fy=60 ksi.