Last Updated on February 8, 2026 by Maged kamel

A solved problem 4-2 for shear Lag factor U for a welded connection.

We continue together with the shear lag factor; how do we evaluate it? We will look at the solved problem-4-2, from Abi Aghayre, from the structural steel design version-3; the solved problem concerns the weld for one leg of an angle.

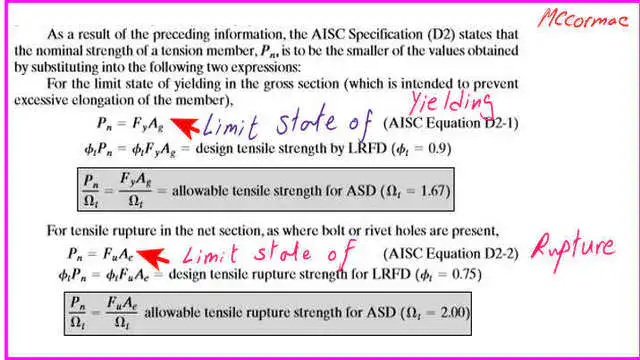

Next are the cases for tensile yielding and tensile Ruptures and how we get the LRFD and ASD tensile design strength.

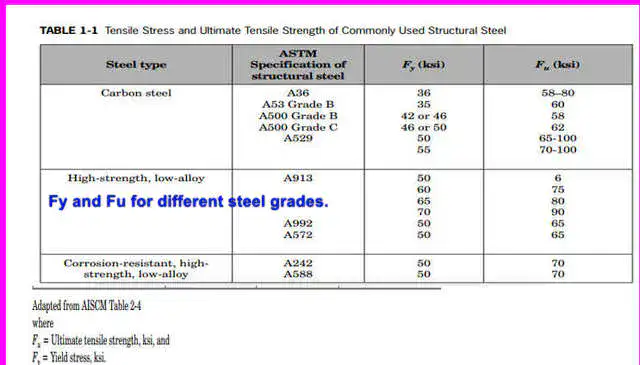

This is the Grade of steel and the corresponding Fy, Fult values for A36, fy=36 ksi, fult=58-80 ksi, A572 grade,fy=50 ksi, A572 grade, the value of tensile point=65 ksi.

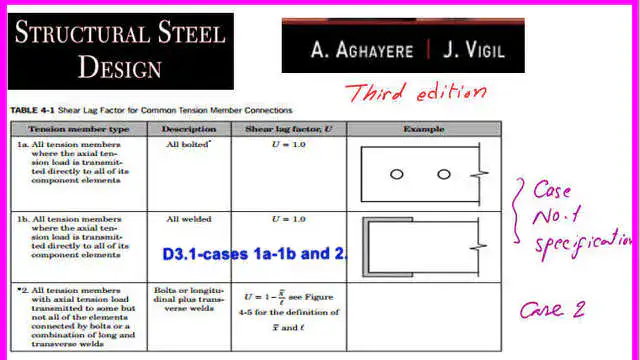

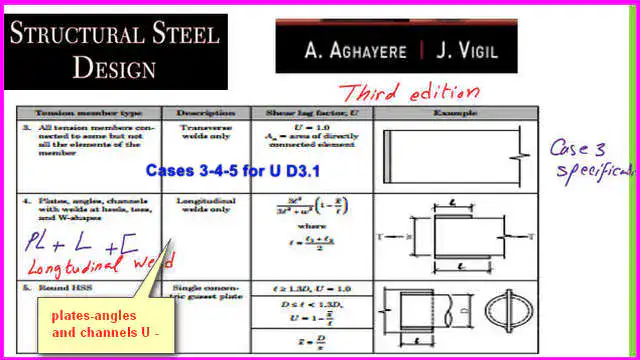

These are the tables as per the latest revision of AISC-360-16, which we are using to estimate the values of the shear lag factor U, In the first table for plates, the three cases of the plates were explained.

Case No. 3 is the case of any tension member welded to another element by a transverse weld, for which the U value is 1.00.

Case No.4a: In this case, plate, angle, C channel, and angle are welded in the longitudinal direction only with tension to another element, for which an equation gives the U value to estimate the U value.

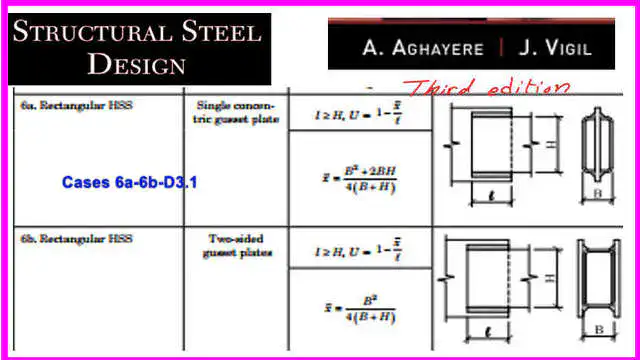

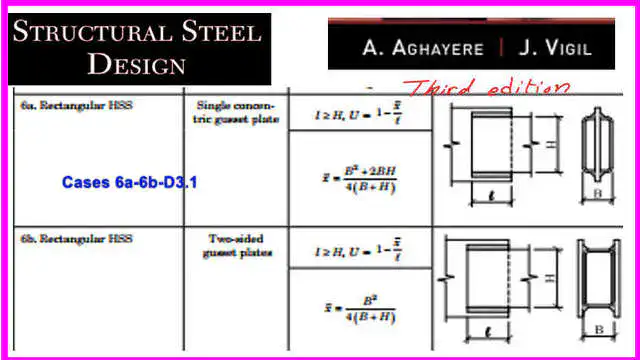

These are the various cases of rectangular connections to a single plate or to two plates, along with the corresponding values for each case.

The next slide image shows the U value for a rectangular HSS in the case of a connection to a single gusset plate and to two gusset plates.

Cases 7 and 8 for the W section and angles, with different connection types and their U values.

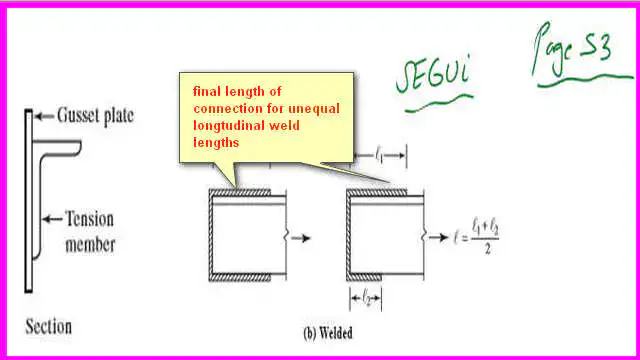

How do we estimate the weld length when weld lengths are unequal?

On page 53 from Prof. Segui’s book, if you have a Tension member that is welded in one leg with a plate in the vertical direction as shown as well as welded at the longitudinal top and bottom edges for the other leg, whether it has an equal weld distance for both upper and lower portion or with a different top and bottom sides distances for which L1 is the weld length for the upper part of the leg with the plate and L 2 is the length of the weld for the lower portion of the leg.

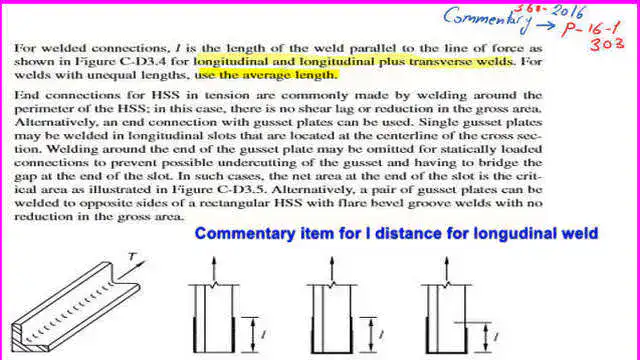

From commentary 16-1, page 303, for a welded connection, L is the length of the weld parallel to the line of force. Here, as shown, the different weld lengths are in the direction of the force. In Fig CD-3.4 for longitudinal and longitudinal plus transverse welds, L is the length parallel to the force.

For different lengths, use the average length, which is now our concern in problem 4-2 on shear lag.

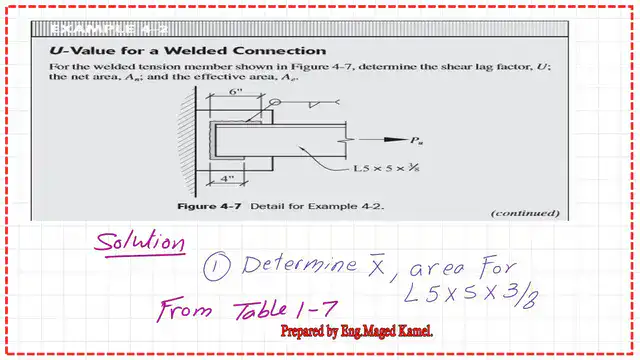

The Solved problem 4-2 for shear Lag factor U.

Evaluate the U value for the welded connection angle L 5x5x3/8 on three sides. Since one leg is not connected, the U value is less than 1. The lower weld length is 4″, and the upper weld length is 6″. The upper leg is welded at the edge with a length equal to the angle height. It is not connected to the backplate.

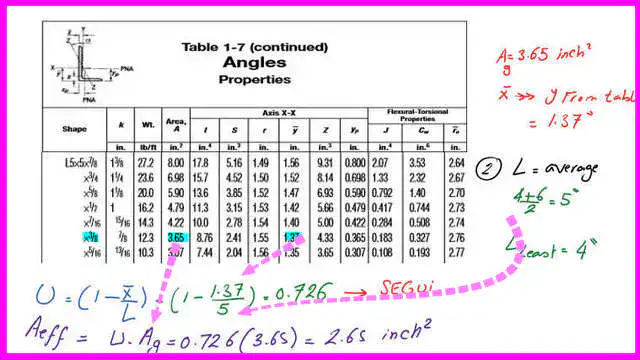

The steps to follow are: first, determine x̅ and the area of the angle. We have an angle of 5x5x3/8″, for which the area is =3.65 inch2. he x̅, which is y̅ value from the table=1.37″

The length of the connection, L, is taken as the average weld length: upper weld length = 6″ and lower weld length = 4″.

L=0.50*(4+6)=5″. The U value equals(1- x̅/L=(1-1.37/5)=0.726.The net area equals the gross area since no bolts are used. The effective area is (0.726*3.65)=2.65 inch2.

The following post will contain two solved problems for the effective net area.

The PDf file for this post can be viewed or downloaded from the following document.

For a more detailed illustration of block shear, there is a very useful external link to the Tension Members chapter 3. A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Chapter 3 – Tension Members– A Beginner’s Guide to Structural Engineering is a great external resource.A Beginner’s Guide to the Steel Construction Manual, 15th ed.

A useful external link –Tensile yielding and tensile rupture. A Beginner’s Guide to the Steel Construction Manual, 16th ed.