Last Updated on February 20, 2026 by Maged kamel

Solved Problem 5-2 For the plastic moment value for W10x60.

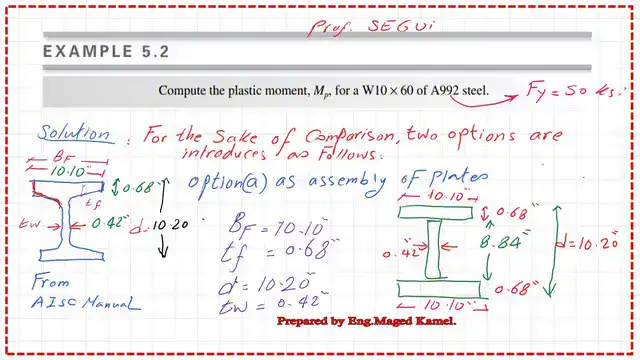

Estimating the plastic moment Mp for the given section, W10x60 of A992, is required.

Using the first option by considering the W section as a group of plates.

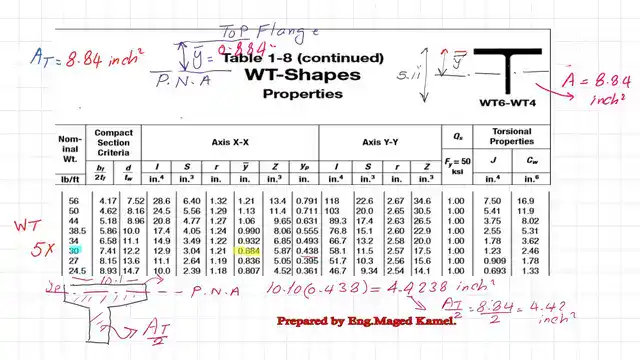

As a first option, I have considered the W section to consist of three plates, for comparison, after evaluating the Zx and Mp. For the first option, as an assembly of plates for the solved problem 5-2. The upper and lower plate dimensions are (10.10″)0.68″, while the intermediate plate dimensions are 8.84″0.42″.

The following pictures show the sequence for that calculation in detail.

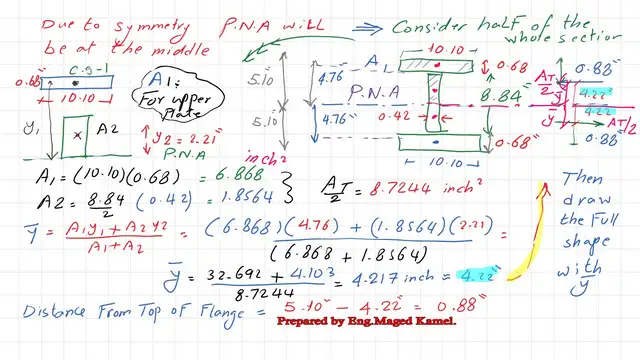

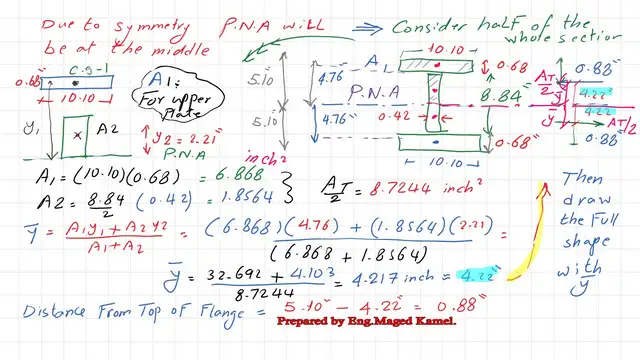

Due to the section’s symmetry, the P.N.A will be in the middle. For A1+A2 areas, where A1 is the upper plate area, its value is 6.868 inch2, while A2 is the area of half of the web. Adding them together will give AT/2, where AT is the total area. The value of AT/2 is 8.7244 inch2.

The next step is to estimate the Cg distance for A1+A2 from the first moment of areas about the P.N.A. The next step is to estimate the Cg distance for A1+A2 from the first moment of areas about the P.N.A.

When we consider the formula AT/2y bar=A1y1+A2y2, we have = Ybar= (6.8684.76+1.8564*2.21)/8.7244, which will be Y bar =4.22″, as we can see from the next slide.

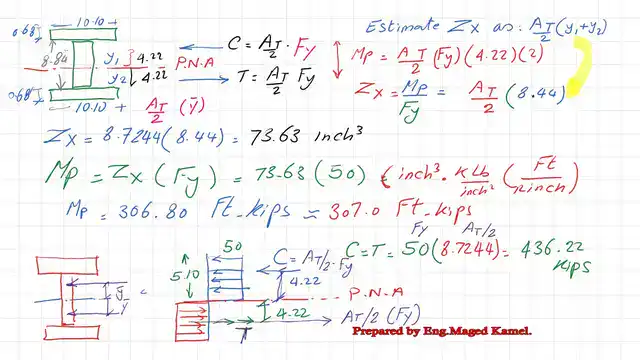

Zx can be estimated as Zx=AT/2(Y1bar+Y2 bar), the AT/2=8.7244 inch2, while Y1 bar=y2 bar=4.22″, then Zx=8.7244(2*4.22)=73.63 inch3.

For the formula Mp = Zx* Fy, the Plastic moment can be calculated as Mp = 73.63* 50 = 3,681.50 in-kips. To convert that value to Ft-kips, just divide by 12. Ultimately, the plastic moment value MP=307.0 Ft- kips for the solved problem 5-2 as an option—a).

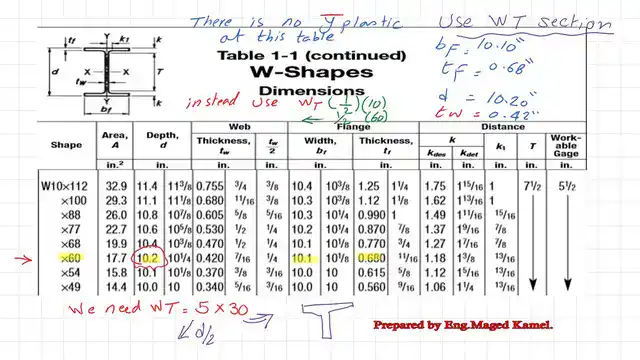

Can we use Table 1.1 to get Zx and Mp?

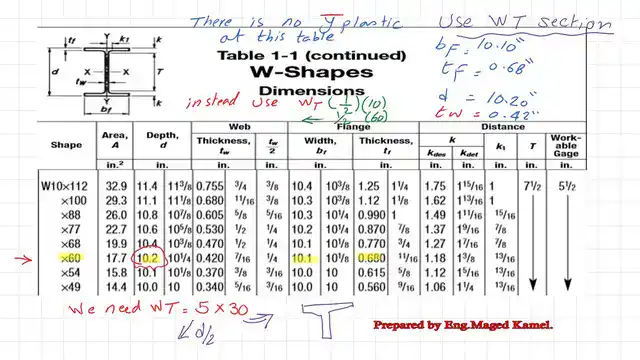

Using Table 1-1 to determine the plastic moment gives us only the Zx value and the section dimensions, such as the W10x60 section in AISC Table 1-1.

The flange width is 10.10″, the tf is 0.68″, the overall depth is 10.20″, and the web thickness is 0.42″. The Zx value is 74.60 inch3. We need the Y plastic to estimate the Mp value, but we cannot find it in that table.

The only solution is to consider W10x60 composed of two Wt sections, each 5×30. We need to proceed to another table.

The plastic section modulus (Z value) of w10x60 is listed in Table 1-1. The Z value =74.60 inch3.

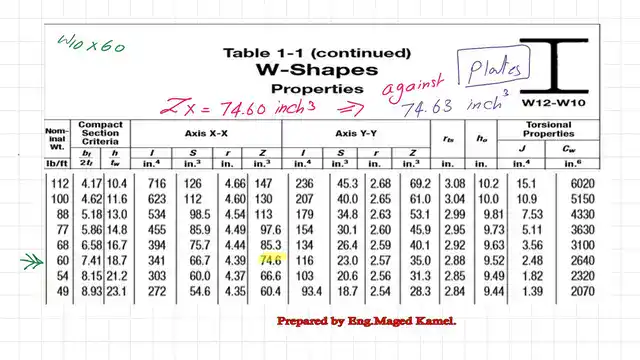

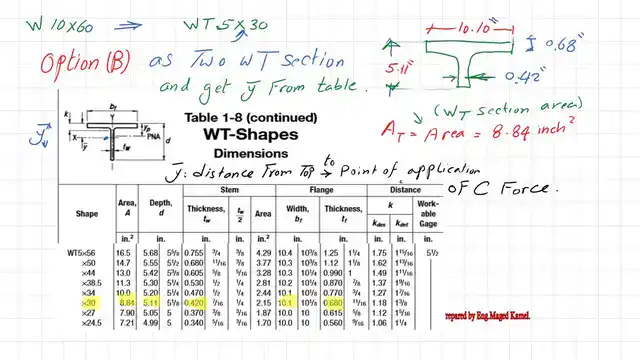

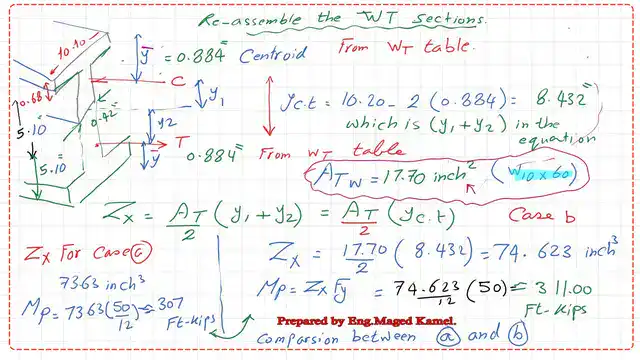

Using the second option by considering the W section as two Wt sections.

The data for the required Wt section of WT5x30 are in Table 1-8. We can get the Y bar from the section property of WT5x30, the value Y bar=0.884″, which is the distance from the plastic neutral axis to the upper top flange, as seen from the next slide.

The total area of the Wt 5×30 =8.84 inch2.

To get the plastic moment, we join the two Wt 5×30 to create W10x60. The compression force C acts at the plastic Neutral axis of Wt, which is 0.884″, as shown in the previous data for WT5x30. The acting Tensile force T, due to symmetry, acts at the plastic neutral axis but at a distance of 0.844″ from the bottom.

The distance between C and T, which we call Yct, is the whole depth(-) 2*yp. the overall depth we can get from table1-1 fr W10x60, which is=10.20″. The compression force C=T=At/2*Fy=(17.70/2)*50==442.50 kips, yct=10.20″-2*0.884=8.432″.

The plastic moment = 442.50*8.432/12 = 310.93 ft-kips, which can be approximated to 311.0 Ft-Kips.

Another way is to consider Mp = Zx* Fy = At/2* yct, which gives the same result as Mp = 311.0 ft · kips.

The following calculation, accompanied by a sketch from the next slide, shows the value of Zx and Mp. For the sake of comparison between options a and b, the values of Mp are written side by side.

The PDf for the data of this post can be reviewed or downloaded.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 16th ed.

For more solved problems, please refer to post 6A- Practice problem 5-2-2, Find y bar, Zx, and Zy.

This is another post: 6b-Practice problem 5-2-3-verify Zx for W18x50.

This is the link for the next post, 7-Local buckling parameters.