Last Updated on December 4, 2025 by Maged kamel

Solved problem-5-1-part 2.

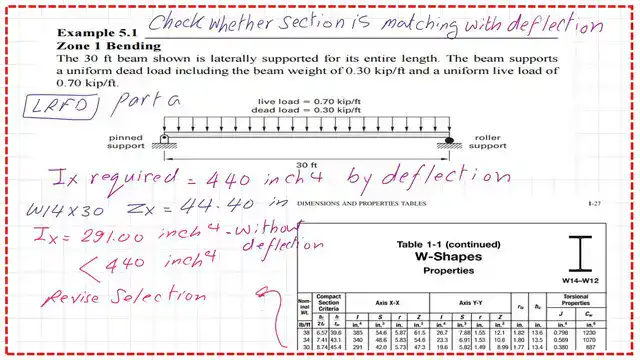

Solved problem-5-1-part 2. is the title of this post, in which we continue solving problem 5.1; we have obtained the required value of the moment of inertia, Ix, as equal to 440 inch4. We have selected W14x30 based on a Zx value of 44.40 inch3; we need to check its Ix value from Table 1-1. The Ix value equals 291.0 inch4, which is smaller than 440.0 inch4. So, we need to revise the selection.

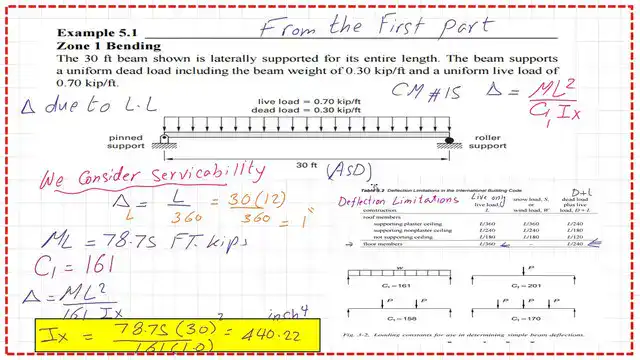

This is a reminder of the Moment of inertia of the required W section based on deflection due to live load, where we have used the factor C1 as equal to 161, and the total moment value Mt and the square value of the length of the steel beam.

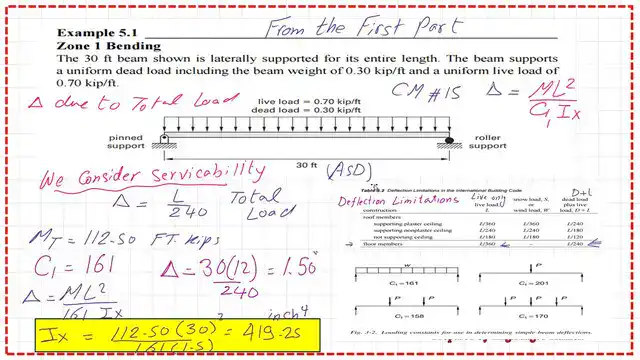

This is a reminder of the Moment of inertia of the required W section based on deflection due to the toL and the square value of the length of the steel beam.

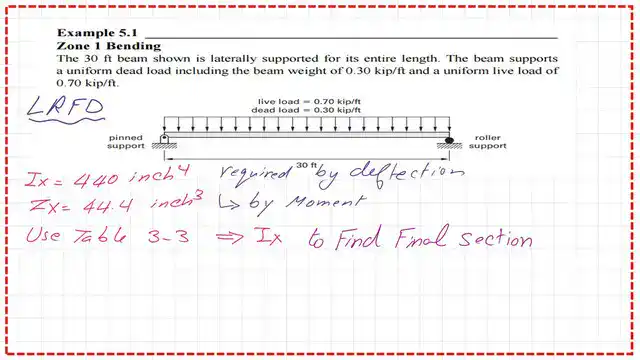

Use Table 3-3 to select a new W section with Ix>or equal to the required value by deflection criteria, which is 440 inch4.

Use Table 3-3 for the solved problem-5-1-LRFD design.

Use Table 3-3 to select a new W and use the bold W18x35. Table 3-3 gives a section Ix equal to 510 inch4, greater than 440 inch4.

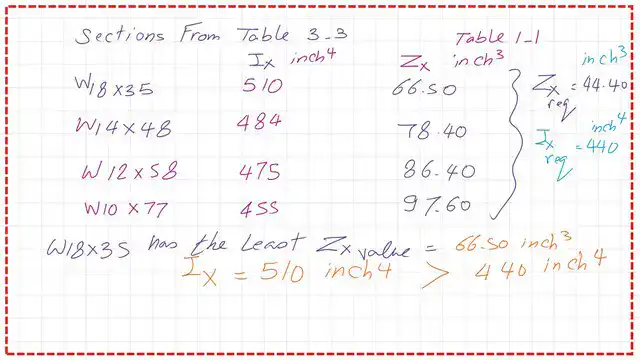

We have selected the first four W sections with Ix bigger than 440 inch4. We need to get the Zx values for these sections and select the final W section.

The next slide images show the data of the four sections and why we have selected W18x35.

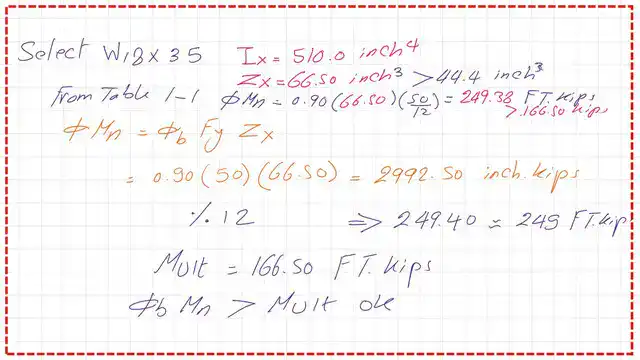

We will estimate the design strength for W18x35 based on the LRFD design. It will be equal 249 ft. Kips, that is bigger than the Ultimate moment, equals 166.50 ft. Kips. Section W18x35 is adequate for design since the available strength is bigger than the ultimate moment.

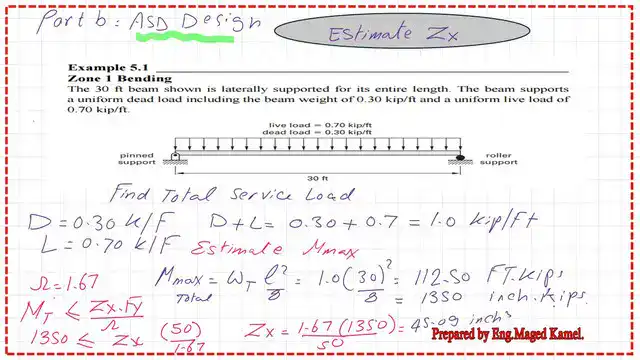

Find the required Zx based on the ASD design.

We need to estimate the required plastic section modulus Zx for the beam based on the ASD design. The total moment based on the data given equals 112.50 ft · kips, and the required Zx value equals 45.09 inch3, the necessary calculation is shown in the next slide image.

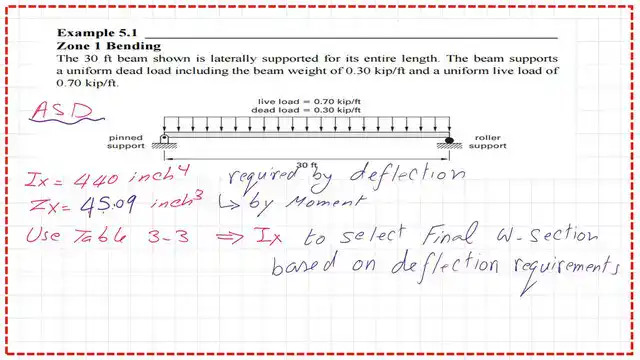

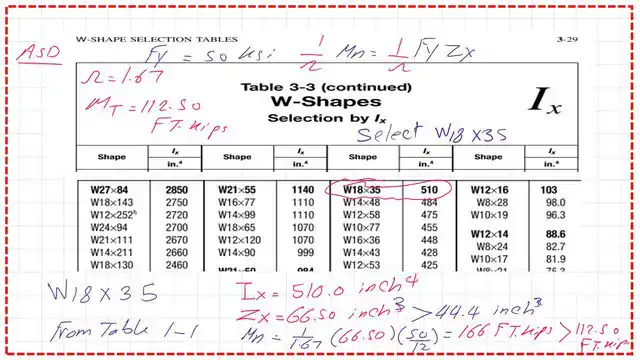

Due to the inertia requirement by deflection control estimation, the required value of inertia Ix is 440 inch4, and the required plastic section modulus Zx is 45.09 inches3; we need to use Table 3-3 based on Ix to find the proper section.

Use Table 3-3 for the solved problem-5-1-ASD design.

Use Table 3-3 to select a new W section and use the bold W18x35. This gives moment of inertia Ix equal to 510 inch4, which is greater than the required moment of inertia 440 inch4.

We have a total moment for the ASd design, equal to 112.50 Ft. kips. Check the allowable strength for W18x35, which is equal to (1/omega)*Mt/Zx*Fy, estimated to be equal to 166.0 Ft. kips. This value is bigger than the Total moment. The section is adequate for design based on the ASD design. Please refer to the following slide image for more information. Thanks a lot.

Test your understanding

This is a new quiz to check your understanding. There are two questions. Please sign in to get a verification of your answer via email.

#1. For the Given solved problem if we change the dead load Wd to 0.70 K/F.Select the required Ix value by total load and by Live load only. ? Ix required by total Load and live load.

![]()

![]()

#2. What is the selected W section?Choose from the following options.

As an external resource for the deflection Chapter 8 – Bending Members

For the next post, 25-part-1-4-solved-problem-9-9-6-1-4, how to find LL for a given slender section?