Last Updated on February 14, 2026 by Maged kamel

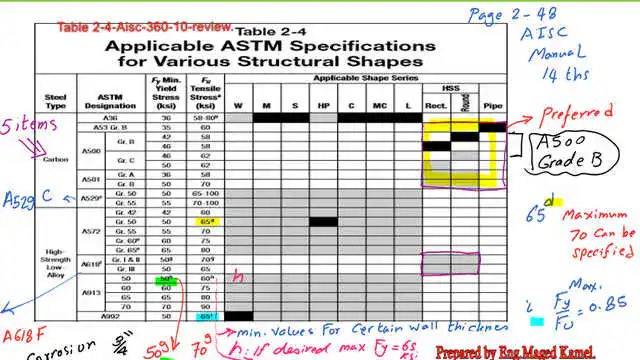

AISC Table 2-4 for various steel elements.

Carbon steel-AISC Table 2-4 for various structural shapes-CM#14.

Carbon steel is classified into five categories, beginning with ASTM A36, ASTM A53 Grade B, and ASTM A500, which includes two grades: B and C.

ASTM A501 has grades A and B, followed by ASTM A592C, which has grades 50 and 55.

What are the preferred material parameters based on the marked black square?

A36 with Fy=36 ksi and Fu=58-80 ksi is ideal for M, S, Mc, and L shapes.

The preferred ASTM A for pipe is ASTM A53 Grade B, with Fy = 35 ksi and ultimate stress Fu = 60 ksi.

For round HSS, the preferred ASTM A is ASTM A 500 grade B with Fy=42 ksi and ultimate stress Fu=58 ksi.

For rectangular HSS ASTM A 500 grade B, Fy=46 ksi and ultimate stress Fu=58 ksi.

The gray squares are for other potential grades and can be utilized if requested. This comprises ASTM A500 grade C and ASTM A501 grades A and B for HS sections.

The white square for the material specification is not applicable.

High-strength alloy steel- CM #14.

There are four groups, including ASTM A572, with five grades of high-strength alloy. Grade 50 is preferred for the HP section, with Fy = 50 ksi and Fu = 65 ksi. We have the symbol d, meaning a maximum tensile strength of 70 ksi can be specified.

Also, we have symbol e for grades 60 and 65, for which grade 60 has yield stress Fy = 60 ksi and ultimate stress Fu = 60 ksi.

While grade 65 has a yield stress of Fy = 65 ksi and an ultimate stress of Fu = 65 ksi, E applies to flange thicknesses of 2 inches or less.

ASTM A 618 f, with grade I and grade ii, with yield stress Fy=50 ksi and Fu=70 ksi, the symbol f stands for it can be specified as corrosion resistant.

ASTM A-913 comes in four grades; the first grade is 50 with Fy=50 ksi with symbol g, which indicates that the minimum Fy of 50 ksi is to be applied with walls nominally ¾ inches and Fu=60 with symbol h, which states that the ultimate stress can be raised to 65 ksi and a maximum yield to tensile stress strength ratio of 0.85 can be specified.

ASTM A 992, preferred for the W section, has yield stress Fy=50 ksi and ultimate stress Fu=65 ksi. Its symbol I stands for the maximum yield to tensile stress strength ratio of 0.85. The carbon equivalent formula is mandatory in ASTM A992.

Corrosion-resistant high-strength low-alloy for various structural shapes-CM#14.

There are three categories of corrosion-resistant, high-strength, low-alloy steels: ASTM A242, grades 42, 52, and 60, with ultimate stress (Fu) from 63 to 70 ksi.

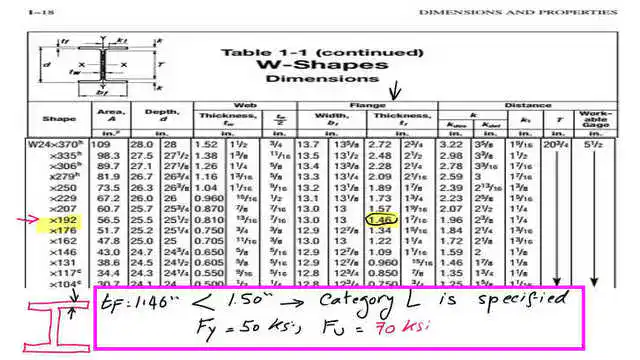

We have symbols J, K, and L. The symbols J, K, and L are related to shapes with flange thickness. J is for flanges with a thickness greater than 2 inches only. Please refer to the next slide.

The specified Fy equals 42 ksi, and the ultimate stress is 63 ksi. For K, the flange thickness is >1.5 inches and <2 inches only. The specified Fy equals 46 ksi, and the ultimate stress is 67 ksi.

L is for flanges with a thickness of less than or equal to 1.50 inches. The specified Fy equals 50 ksi, and the ultimate stress is 70 ksi. The second group is for ASTM A588, with Fy = 50 ksi and Fu = 70 ksi.

ASTM A572 contains five classes, ranging from 42 to 65; hence, the required grade must be given. The Fy and fu were chosen based on the flange thickness in the next slide.

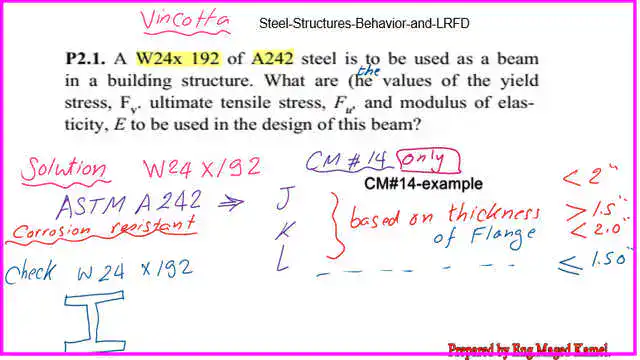

Solved problem for ASTM A242.

ASTM A 242 is specified for a beam with W24x192; it is required to find the yield stress Fy and Fu values for the beam and the modulus of elasticity; this practice problem is only given for CM#14. As a reminder, A242 was used as a corrosion-resistant material in tables 2-4 and later removed from CM#14 for corrosion resistance; it was available for the W section and was grey.

Now, it is used for plates. Based on the flange thickness, there are three yield stress grades: 42, 46, and 50 ksi, marked J, k, and l, respectively.

Based on Table 1-1, the flange thickness is 1.46 inches, which is less than 1.50 inches; we will select grade 50, category L, and the ultimate stress Fu is 70 ksi. The modulus of elasticity is 29×10^6 psi.

The second part of the solved problem is shown in the next slide.

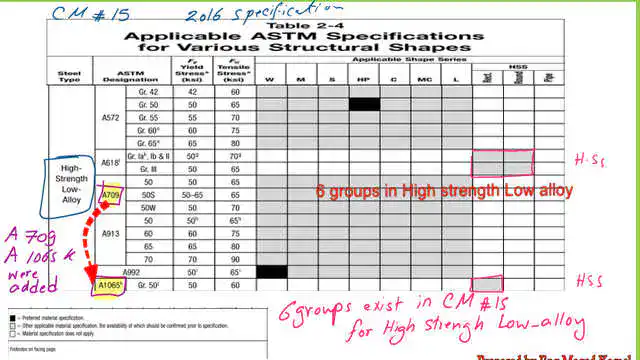

AISC Table 2-4 for various structural shapes-CM#15-CM#16.

I have included a snapshot of Table 2-4 to quickly review the main difference between CM #14 & CM #15. The carbon steel categories have increased to 8 items, and the HSS sections have also changed.

Two steel grades are added for High-strength, low-alloy: A709 and A1065.

ASTM A242 steel was removed from table 2-4-CM#15 for corrosion resistance, and ASTM A1065 steel was added.

The 2016 Specification for Steel, regarding materials, is shown on the next slide.

The latest AISC Specification AISC-360-22 for steel materials is shown on the next slide.

#1. Find the gross and net area for a plate of 8x 3/4″ with 7/8″ bolt.

#2. What is the preferred grade for W sections?

#3. What is preffered grade for HSS pipe section?

The PDF data for this post can be downloaded and reviewed. Please refer to the following PDF document.

Please refer to the previous two posts for an introduction to tension steel design.

1- A step-by-step introduction to tension members.

The previous post is a Review of AISC Tables 2-5 for plates.

For a useful external Chapter 3 – Tension Members– Bartlett Quimby