Last Updated on June 26, 2025 by Maged kamel

- Solved problem 5-part 1 for design shear strength.

- Solved problem 5-part 1 for design shear strength for sizes 5/8", 3/4", and 7/8 inches for A325-N type.

- Solved problem 5-part 1 for design shear strength for size 1" for A325-N type.

- Solved problem 5-part 1 for design shear strength for sizes 5/8", 3/4", 7/8 and 1 inch for A325-N type using Table 7-1.

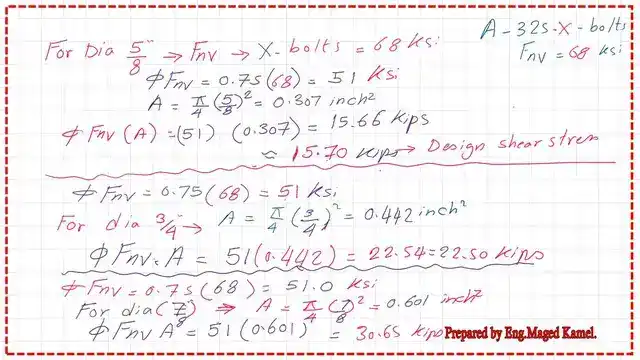

- Solved problem 5-part 1 for design shear strength for sizes 5/8", 3/4", and 7/8 inches for A325-X type.

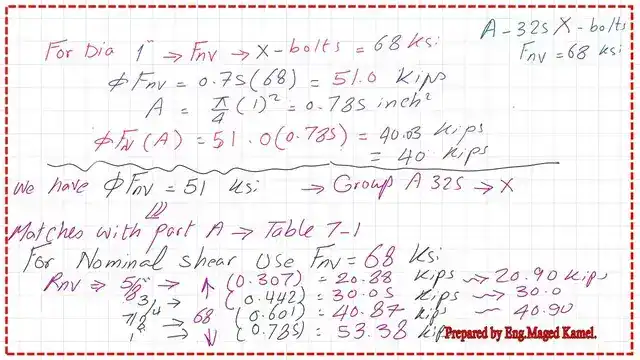

- Solved problem 5-part 1 for design shear strength for size 1" for A325-x type.

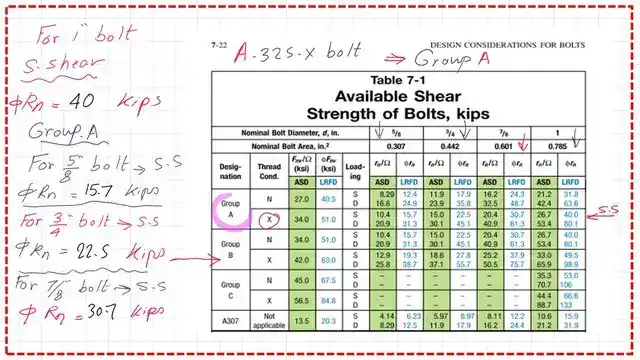

- Solved problem 5-part 1 for design shear strength for sizes 5/8", 3/4", 7/8 and 1 inch for A325-X type using table 7-1.

Solved problem 5-part 1 for design shear strength.

This post will introduce the solved problem 5-part 1 for design shear strength, quoted from the Unified Design of Steel Structures handbook, 3rd and 4th editions. To find the design shear strength for different types of bolts with different bolt diameters, develop a table showing the design shear strength or use the LRFD design for shear strength.

The following slide provides a summary of the post’s content and explains the content of Practice Problems 1 and 2 in the Unified Steel Design of Steel Structures.

The first type of bolt is type A 325-N, where N indicates that the threads are included in the shear plane of the bolt. Based on Table J3.2, the nominal shear strength is 54 ksi for a single shear plane. The limit state of the shear design is 0.75.

The following slide image is a reminder of the Fnv or the nominal shear value for Group A-325N and x bolts, and how we have derived the expression.

Solved problem 5-part 1 for design shear strength for sizes 5/8″, 3/4″, and 7/8 inches for A325-N type.

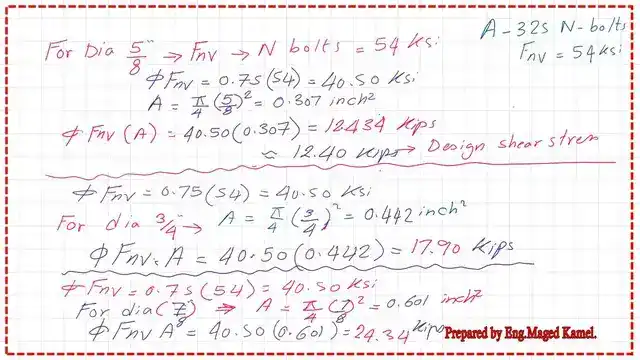

We start with a 5/8″ Type A-325 N diameter bolt with a nominal shear strength of 54 ksi. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which is equal to (0.75*54)=40.50 ksi

To get the shear strength for one bolt with a diameter of 5/8 inch, estimate the area of the bolt. The area is equal to 0.307 inch2. We get the design shear value by multiplying (Φ*Fnv*A)=(40.50* 0.307)=12.40 kips.

For the second bolt with a diameter of 3/4″, Type A-325 N with a nominal shear strength of 54 ksi. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which is equal to (0.75*54)=40.50 ksi

To get the shear strength for one bolt, estimate the area of the bolt with a diameter of 3/4 inch. The area is equal to 0.442 inch2. We get the design shear value for a 3/4-diameter bolt type -325 N by multiplying (Φ*Fnv*A)=(40.50*0.442)=17.90 kips.

The third bolt has a 7/8″ Type A-325 N diameter with a nominal shear strength of 54 ki. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which equals (0.75*54)=40.50 ksi.

To get the shear strength for one bolt, estimate the area of the bolt with a diameter of 7/8 inch. The area is equal to 0.601 inch2. We get the design shear value for a 7/8-inch diameter bolt type -325 N by multiplying (Φ*Fnv*A)=40.50*0.601=24.34 kips. Please refer to the next slide for more details.

Solved problem 5-part 1 for design shear strength for size 1″ for A325-N type.

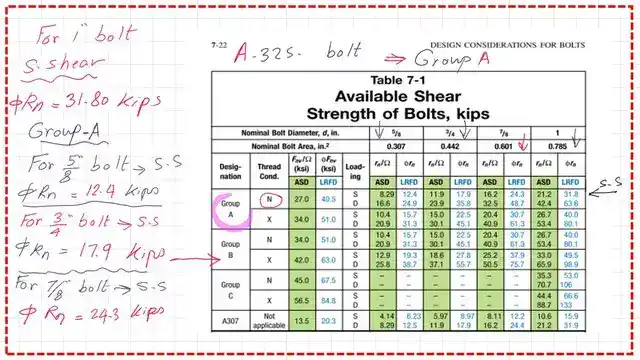

The last bolt has a diameter of 1 inch, Type A-325 N with a nominal shear strength of 54 ksi. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which equals (0.75*54)=40.50 ksi.

To get the shear strength for one bolt with a diameter of 1 inch, estimate the area of the bolt. The area is equal to 0.785 inch2. We get the design shear value for a 1-inch diameter bolt type -325 N by multiplying (Φ*Fnv*A)=40.50*0.785=31.80 kips.

Please refer to the next slide for more details. I have added the Nominal shear strength values for Problems 1 and 2 of the Unified Design of Steel Structures handbook, 3rd and 4th editions.

Solved problem 5-part 1 for design shear strength for sizes 5/8″, 3/4″, 7/8 and 1 inch for A325-N type using Table 7-1.

We can use Table 7-1 for the available shear strength for bolts to verify our estimations. We refer to Group A as N-type. We use the diameter of 5/8 inch with a single shear termed S. We can find that the design shear strength for the bolt is equal to 12.40 kips

We use the diameter of 5/8 inch with a single shear termed S. We can find that the design shear strength for the bolt is equal to 17.90 kips

We use a diameter of 7/8 inch with a single shear termed S. We can find that the design shear strength for the bolt is equal to 24.30 kips

for the last diameter of 1 inch with a single shear termed S. We can find that the design shear strength for the bolt is equal to 31.80 kips. The previous values match our calculations. Please refer to the next slide image.

Solved problem 5-part 1 for design shear strength for sizes 5/8″, 3/4″, and 7/8 inches for A325-X type.

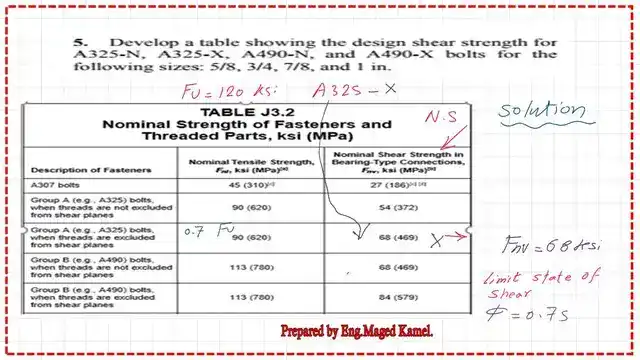

The second type of bolt is type A 325-X, where X indicates that the threads are not in the bolt’s shear plane.

Based on Table J3.2, the nominal shear strength equals 68 ksi for a single shear plane. The limit state of the shear design is 0.75.

We start with a bolt with a diameter of 5/8″ Type A-325X with a nominal shear strength of 68 ksi. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which is equal to (0.75*68)=51 ksi

To get the shear strength for one bolt with a diameter of 5/8 inch, estimate the area of the bolt. The area is equal to 0.307 inch2. We get the design shear value by multiplying (Φ*Fnv*A)=(51* 0.307)=15.70 kips.

For the second bolt with a diameter of 3/4″ Type A- to get the shear strength for one bolt estimate the area of the bolt with dia 3/4 inch, the area is equal to 0.442 inch2.

We get the design shear value for a 3/4-diameter bolt type -325 X by multiplying (Φ*Fnv*A) = 51* 0.442 = 22.50 kips.

To get the shear strength for one bolt, estimate the area of the bolt with a diameter of 7/8 inch. The area is equal to 0.601 inch2. We get the design shear value for a 7/8-diameter bolt type -325 X by multiplying (Φ*Fnv*A)=(51*0.601)=30.65 kips.

Solved problem 5-part 1 for design shear strength for size 1″ for A325-x type.

The last bolt has a diameter of 1 inch Type A-325 X with a nominal shear strength of 68 ksi. We estimate the design shear strength per inch^2 by multiplying Φ*Fnv, which equals (0.75*68=51.0 ksi.

To get the shear strength for one bolt with a diameter of 1 inch, estimate the area of the bolt. The area is equal to 0.785 inch2. We get the design shear value for a 1-inch diameter bolt type -325 X by multiplying (Φ*Fnv*A)=51*0.785=40 kips. Please refer to the next slide for more details.

Please refer to the next slide for more details. I have added the Nominal shear strength values for Problem 2 of the Unified Design of Steel Structures handbook, 3rd and 4th editions.

Solved problem 5-part 1 for design shear strength for sizes 5/8″, 3/4″, 7/8 and 1 inch for A325-X type using table 7-1.

To verify our estimations, we can use Table 7-1 for the available shear strength for bolts. We refer to group A with X-type, and we use the diameter of 5/8 inch with single shear termed S. We can find that the design shear strength for the bolt is equal to 15.70 kips.

We repeat the same steps for the other diameters: 3/4″,7/8″, and 1″. All the values match our previous calculations.

Thank you very much, and I look forward to seeing you in the next post.

This is the link to the following post, part two. The second part will include the design shear strength for A490-N and A490x bolts.

This link is for the previous post, ‘A Solved Problem 12-1 Part 2 for Bearing Connections.

This is a very useful source for designing various Steel elements: A Beginner’s Guide to the Steel Construction Manual, 15th ed, Chapter 4—Bolted Connections.