Last Updated on February 19, 2026 by Maged kamel

How can we estimate Y bar, Zx, and Zx for an I shape that is symmetric about the Y axis only? That is the Topic of this post.

- Practice problem 5-2-2: Find y bar, Zx, and Zy for the unsymmetric section.

- Practice Problem-5-2-2 from the steel design handbook.

- The distance Y bar from the top of the shape to the P.N.axis.

- The distance C1 from the compression force to the P.N axis.

- The distance T1 from the Tension force to the P.N axis.

- The Plastic Moment about P.N axis-part b.

- The value of a section modulus about the minor axis y.

Practice problem 5-2-2: Find y bar, Zx, and Zy for the unsymmetric section.

Practice Problem-5-2-2 from the steel design handbook.

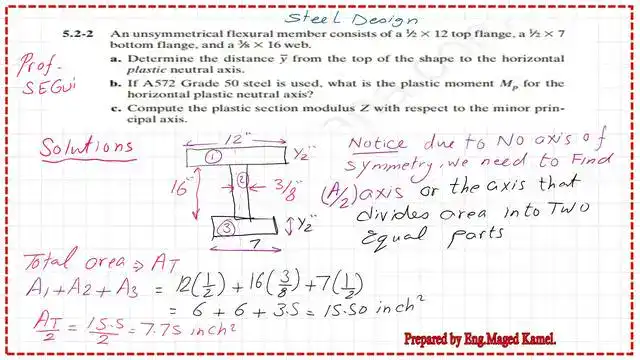

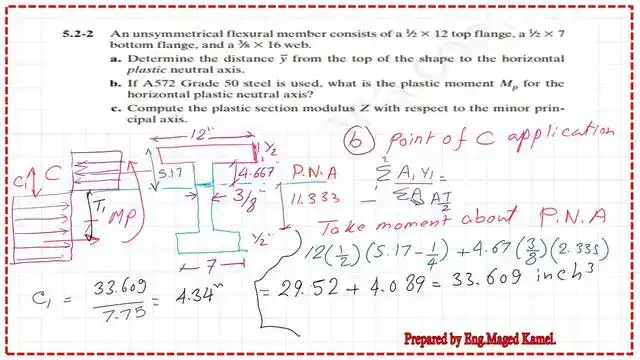

There is an unsymmetric flexural member consisting of three parts. The upper flange is 12×0.50 inches, the web part is 3/8”x 16”, and the lower flange is 7×1/2”. There are three requirements: a), b), and c).

For Part a), determine the y-bar or the distance from the top of the upper flange to the plastic neutral axis.

First, we estimate the total area of the three parts: the upper flange has an area of 12 x 1/2, the web has an area of 16 x 3/8, and the lower flange has an area of 7 x 1/2. The total area is 15.50 in^2.

First, we estimate the total area of the three parts: the upper flange has an area of 12 x 1/2, the web has an area of 16 x 3/8, and the lower flange has an area of 7 x 1/2. The total area is 15.50 in^2.

The distance Y bar from the top of the shape to the P.N.axis.

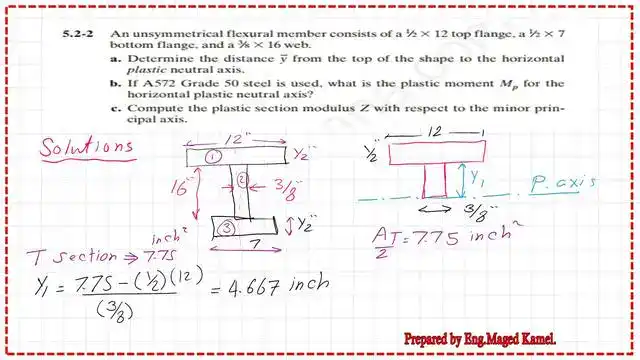

On the next slide, since the area of the top flange is less than At/2, the plastic neutral axis cannot cross the upper flange; it is located below the upper flange by a distance y1.

After checking, we can find the y1 value by equating the difference between At/2 and the upper flange area to the product of (3/8 y1). y1 will be equal to 4.667 inches.

In the third slide, we will estimate the y-bar distance, which is the distance from the top of the upper flange to the P.N axis.

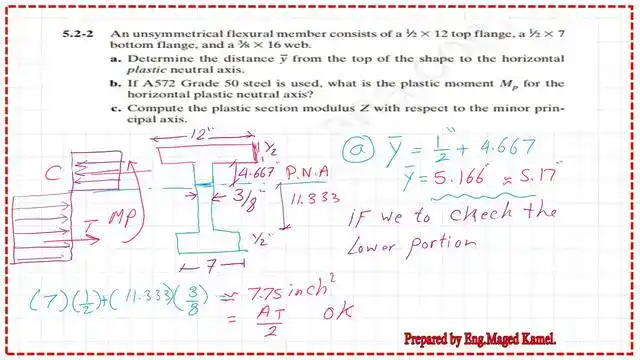

If we add ½ inch to y1, the y-bar will be 5.166 inches, rounded to 5.17 inches. We could check the area of the lower portion to ensure it equals At/2.

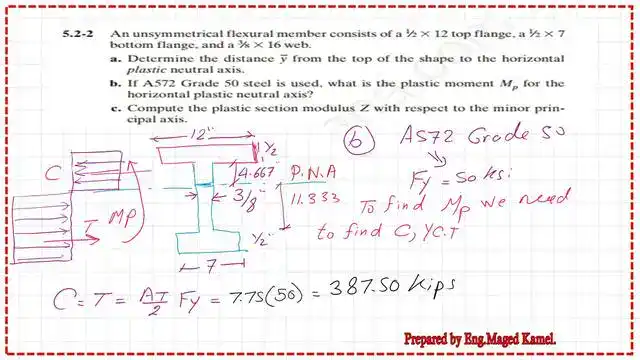

On the next slide, as required by item b), find the Plastic moment for A572 grade 50 steel. The yield stress Fy equals 50 ksi. We will estimate the compression force C, which equals At/2*Fy = 7.75*50 = 387.50 kips.

The distance C1 from the compression force to the P.N axis.

We will estimate the C1 distance, which is the distance from the point of application of force c to the P.N.A. The value of c1 can be estimated by taking the first moment of area for the upper half of the section about the P.N.A.The moment of area equals 33.609 inch3.

When we divide the first moment of the area by At/2, we find that the value of C1 equals 4.34 inches.

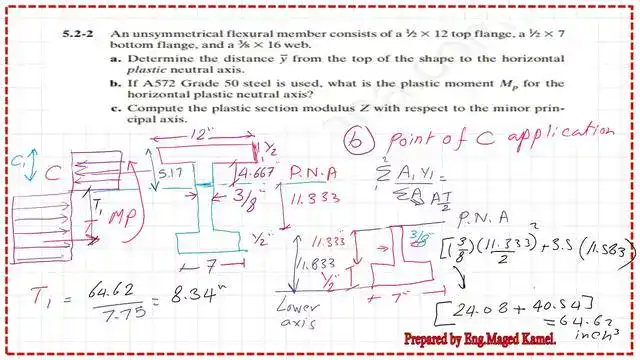

The distance T1 from the Tension force to the P.N axis.

We move to the next slide to estimate the distance T1, which is the distance from the point of application of Force T to the P.N.A. Since we do not have symmetry, we expect a value different from c1.

Again, we will estimate the moment of area of the lower half of the section, which is the sum of the moment of area of the lower flange and the web area part below the P.N axis. The value of T1 equals 8.34 inches.

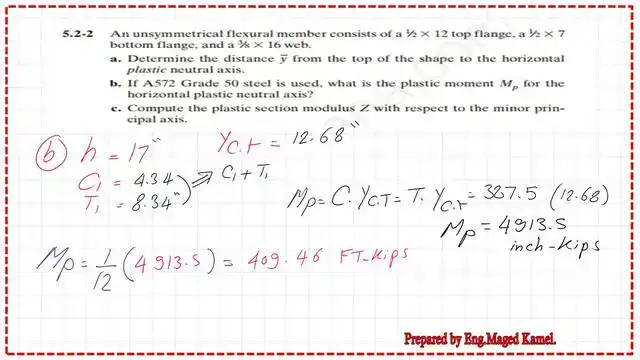

In the next slide, we have the values of the C and T forces and c1 and T1, the two distances. Mp equals C*(C1+T1) or C*yct, which is the vertical distance between force C and force T.

The Plastic Moment about P.N axis-part b.

The Mp value equals (387.50×12.68); we divide by 12 to find the value of Mp in Ft-kips. The Mp value is equal to 409.46 Ft-kips, which is the requirement for item b).

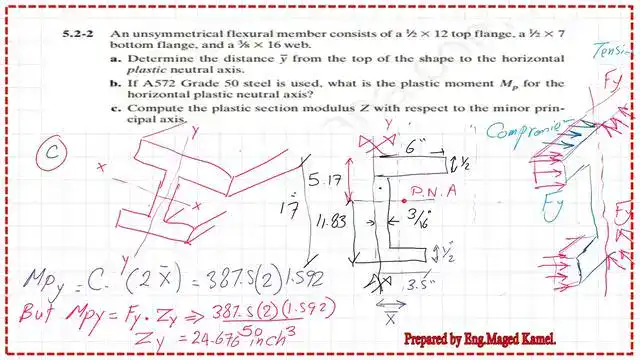

The value of a section modulus about the minor axis y.

Due to symmetry about axis y, we will deal with the C-shape section, find the first moment of area about the y-axis, and divide by the sum of the three shapes. We will find that X-bar equals 1.592 inches.

Finally, we will estimate the yielding Moment My (C*2x bar) and divide by Fy. The final value of the plastic section modulus about Y, and Zy equals 24.676 inch3.

The PDf for the data of this post can be reviewed or downloaded.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 14th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 15th ed.

Here is the link to Chapter 8, “Bending Members.” A Beginner’s Guide to the Steel Construction Manual, 16th ed.

The next post, Post 6b, is Practice problem 5-2-3-verify Zx for W18x50.

The next post is “A Guide to Local Buckling Parameters for Steel Beams.