Last Updated on February 18, 2026 by Maged kamel

Introduction to Tension Members.

Introduction to tension members- tension yielding.

We will begin a new subject, Introduction to Tension Members.

The first section discusses where to employ the tension members.

The second item is the AISC chapter, which governs the design of tension members.

The third item explains the difference between net and gross areas. The gross area is the section area, excluding any deductions for fasteners.

The net area is the section’s area minus the area of the fastener. Later, we’ll look into allowances for fasteners like bolts.

There are net and special tables for determining the final value of the effective net area.

The fourth component discusses tensile yielding &tensile rupture, as well as gauge line information.

The fifth component provides the design parameters for tension members in the LRFD and ASD, the reduction factors φt and Ωt.

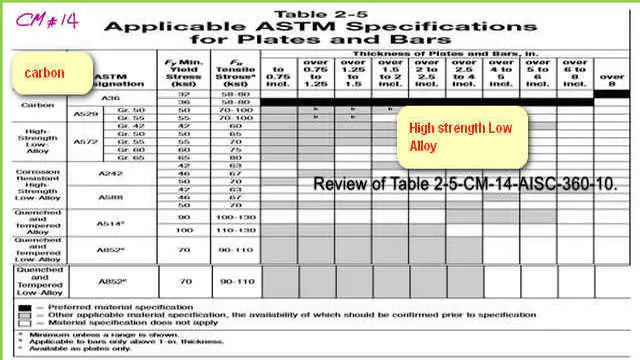

The sixth item is the tables for various shapes, the relevant yield, and the F ultimate stresses for tension members.

Tension members are used for bridges, roof trusses, towers, and bracings. Tension members are considered when used as tie rods.

Selecting a section to be used as a tension member is one of the simplest problems encountered in design, compared with columns and beams, so tension member design is considered simple.

The related division in the specification for Tension members.

The next slide includes the chapter used for the design of tension members, and then shows the section in the chapter for tension members. Chapter D is used. D-2 governs the Tensile strength. AISC-360-16 page 16-1-28.

There are two items: Tensile Yielding and Tensile rupture. For tensile yielding, the P nominal is estimated as equal to the product of Fy*Ag, where Fy is the yield stress, and Ag is the gross area.

For the design strength, multiply by φt =0.90. While for the allowable strength, multiply by (1/ Ωt) where Ωt=1.67.

Item b) is for tensile rupture at the places of bolts or welds. The nominal load Pn = Fu*Ae, where Ae is the effective area.

However, the LRFD parameter differs: for tensile rupture φt =0.75, less than the value given for tensile yielding, which is 0.90.

For the ASD design, based on the relation φ*Ω = 1.5, then Ωt = 2.00. Fy is the yield strength, and Fult is the ultimate strength. D-3 includes the effective net area and is to be estimated from B 4-3: Aeff = Anet* U factor, U, shear lag factor = 1.

In the next slide, we can see two cases. The first case is when the two members are fully connected, such as a bolted plate and a spliced channel. The effective area equals the net area, and the u factor, the shear lag factor, equals one.

Whenever two channels are connected only at the upper and lower flange, while the web areas are not connected, the effective area will be considered smaller than the net area, and the U value will be less than one.

This is the provision from the AISC code for the net area for tension members and the different terms used.

The shear lag factor, U value, is obtained from Table D3-1.

Tension yielding.

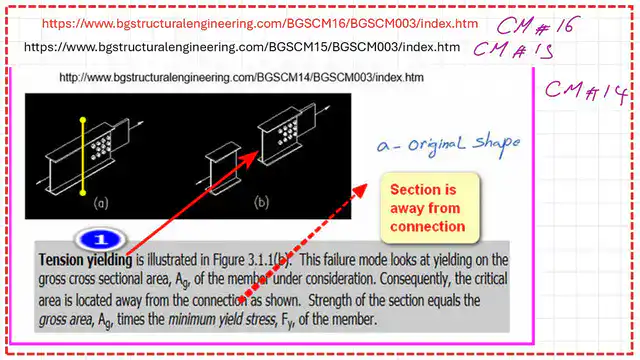

The tension yield picture was quoted from the external link—A BEGINNER’S GUIDE TO THE STEEL CONSTRUCTION MANUAL, 14TH ED.

The latest link is here, based on the construction manual #16.

As an introduction to tension members, we would want to examine the various failure modes.

There are many good illustrations, such as a section for the W section; if we deal with tension yielding, there is a failure mode in the positions distant from the bolts. When tension forces are applied at the ends, failure will occur at a location other than along the bolts’ path.

This failure mechanism focuses on yielding in the gross cross-sectional area.

T=Ag*Fy calculates the tension force at failure. An is the original shape, and b is after the section’s tension yielding.

Tensile Rupture Types.

This is the first failure—a vertical line passed by the line of the bolts in a direction perpendicular to the force direction.

The second failure is shown here as a zigzag line, from which the net area was estimated. We must consider the spacing S and the perpendicular distance g between bolts.

The damage occurs due to the Punching of a hole.

Looking back at Prof McCormack’s notes, he stated that the long-standing practice is to punch holes 1/16 inch larger than the bolts.

When this technique was followed, punching a hole was expected to harm or destroy an additional 1/16 inch of the surrounding metal. In actuality, add 1/16+1/16 inch to the diameter of the bolt.

The PDF data for this post can be downloaded and removed. Please refer to the following PDF document.

The following post contains an Easy introduction to Tension members-part-2.

For a useful external Chapter 3 – Tension Members– Bartlett Quimby