How to find the workable gauge line distances for an angle?

Types of limit states for Tension Members.

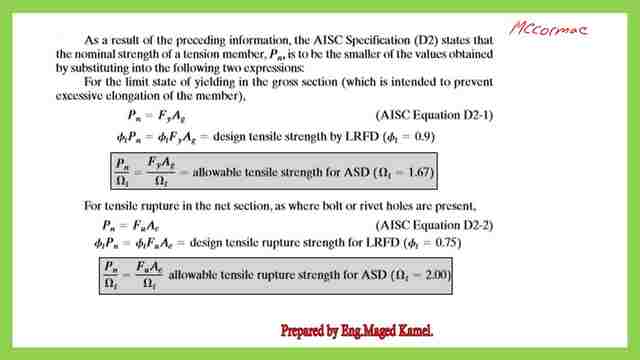

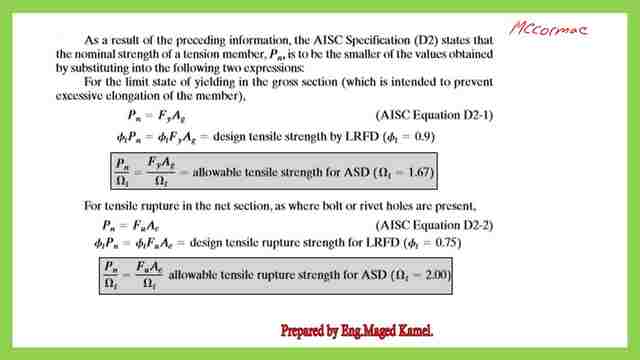

This summarizes the Limit states for the tension members; two conditions are considered, limit state of yielding and limit state of rupture.

We will review the important equations used for the Nominal strength for tensile members according to failure phenomena. If yielding, the Pn=fy*Ag, where Fy is the yield stress and Ag is the gross area.

The parameter of the LRFD, is φt=0.90, while the parameter of the ASD, is Ωt=1.67.

A split due to the fracture takes place, passing through line-crossing bolts.

For the second case of tensile rupture, the LRFD parameter φt=0.75, while Ωt=1.67=2.0.

Our main equation, Pn=fult*Aeff, compares the two cases and selects the lesser value, and selects the lesser value after considering the application of the various coefficients. Comparing the LRFD cases Together, if wishing to check based on LRFD, then include the φt.

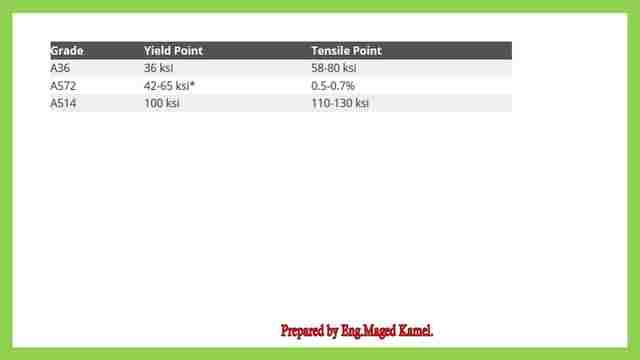

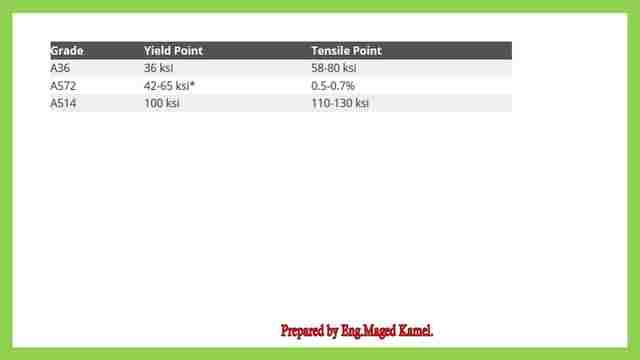

While for ASD, consider the Ωt for each of the two failure cases, then take the lesser value. The next slide shows the different values for the Fy, Fult for various types of ASTM A36, ASTM A572, and ASTM A514.

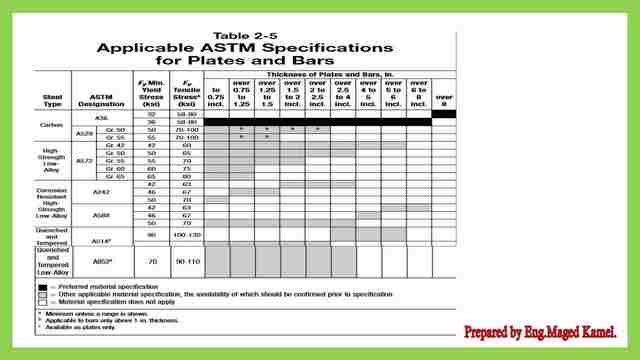

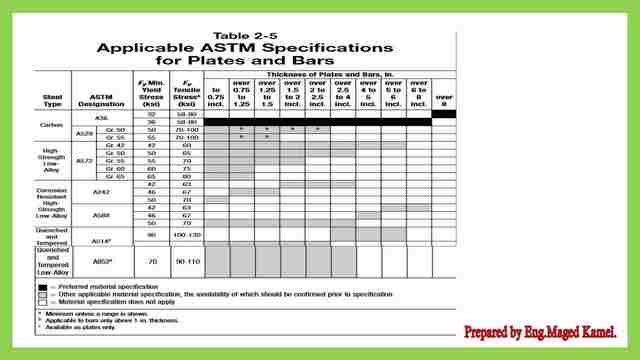

Table 2-5, the title is the Applicable ASTM specifications for plates and bars. Table 2-5 for the Applicable ASTM specifications for Plates and bars.

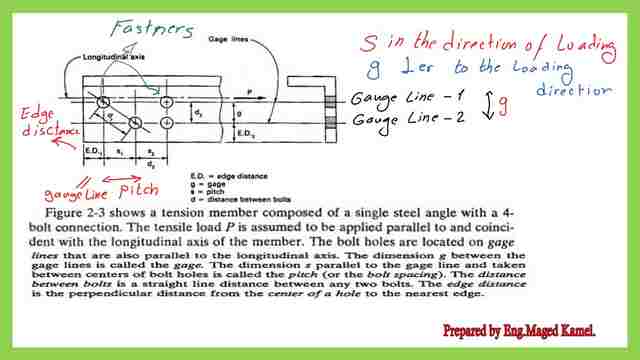

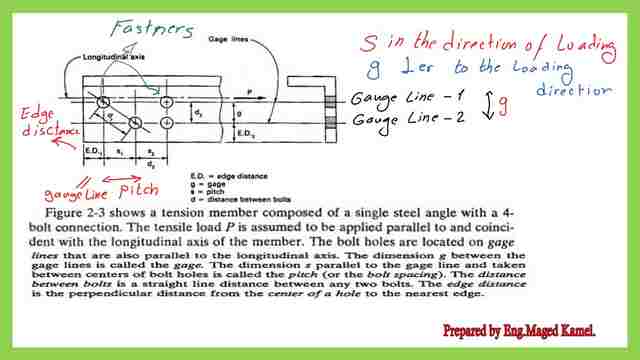

Detailed Sketch for the gauge lines.

The next slide is a review of the gauge lines. The first gauge line and the second gauge line are in the direction of the force.

The vertical distance between the gauge lines is g, and the distance between the centerlines of bolts is S, which is called the pitch.

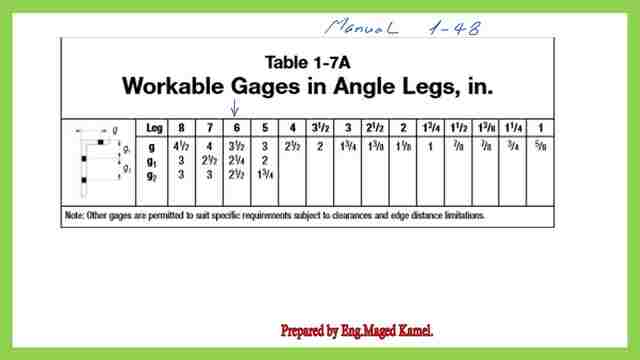

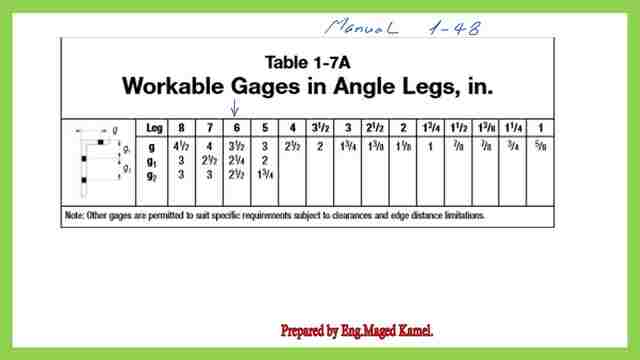

Workable gages in angle legs in inches-Table 1-7A.

The next slide includes table 1-7A, for an angle, whether equal or Unequal angle.

This table gives the workable gages in angle leg in inches. For instance, as per our example for an angle 6×4 inch, then from the leg of the angle, if we wish to put one line of bolts, use the first horizontal represented by g for the 6-inch leg. We select 3 1/2 inches, while the gauge distance g1 the distance is =2 1/4, while for the second gauge line, the gauge distance =2 1/2 inches. For a 4×4 inch angle, there is no g1 or g2, which means that one line of bolts is allowed only.

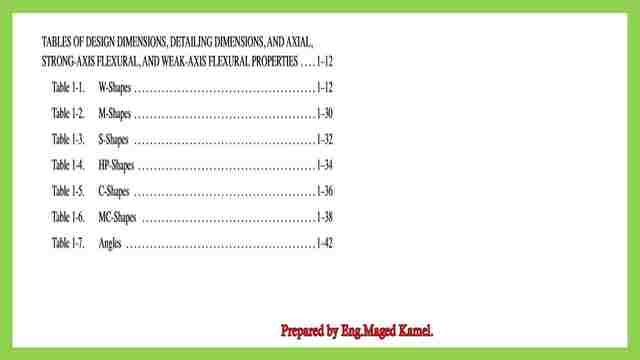

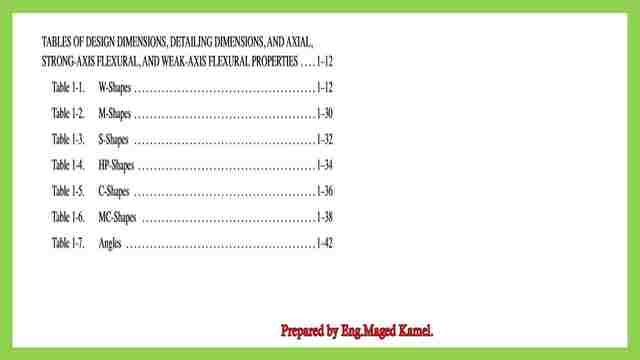

The tables for the different shapes are shown. We can get the required properties, area, Ix, Iy, rx, and ry, etc.

Hp shapes, c shapes Mc shapes, angles to get the required properties, area, Ix.Iy, rx and ry, etc. W shapes, wide flange shapes.M shapes.

Starting 1-30 from the AISC manual starting from pages 30 to 31, data for the S shape from page 32, then Hp shapes for piles sections, c channels from 1-36, while for the M-C shapes from 1-38, and the angles from page 1-42.

Table 1-1 for W shapes.

Table 1-2 for M shapes.

Table 1-3 for S shapes. Table 1-4 for HP shapes.

Table 1-5 for C shapes.

Table 1-6 for MC shapes.

Table 1-7 for angles.

The next slide shows how to estimate the gauge distance for an angle by considering the centerline distance between the center of bolts.

From Prof. Salmon’s book, if there is a section for an angle. The given ga is the first gauge line, as shown on the lower side of an angle measured from the edge of the angle to the centerline of the fastener. At the same time, gb is the distance measured from the edge to the centerline of the fastener but vertically.

The g, gauge distance between the centerlines of bolts is estimated by converting the angle into a plate looking from the inner side of the angle.

The distance between the cl of the bolts, g=ga + gb – t/2-t/2, so finally=ga+gb-t, where t is the thickness of the angle.

This is the pdf file used for the illustration of this post.

The next post is Solved problems for the net area estimation

For a good reference–Types of tension members in structural steel construction.