- Solved problem 10-1, bearing value-LRFD-part 2 of 3.

- A solved problem 10-1-How to get the value of bearing and tear-out for a bearing connection?

- Review of the necessary tables that are needed for the bearing nominal strength estimation.

- The nominal bolt-hole dimension.

- A solved problem 10-1- how to get the value of bearing value-LRFD for a connection?

- Using Table 7-4 for the Nominal value of the bearing value-LRFD for inner bolts.

- Using Table 7-5 for the Nominal value of the bearing value-LRFD for external bolts.

Solved problem 10-1, bearing value-LRFD-part 2 of 3.

A solved problem 10-1-How to get the value of bearing and tear-out for a bearing connection?

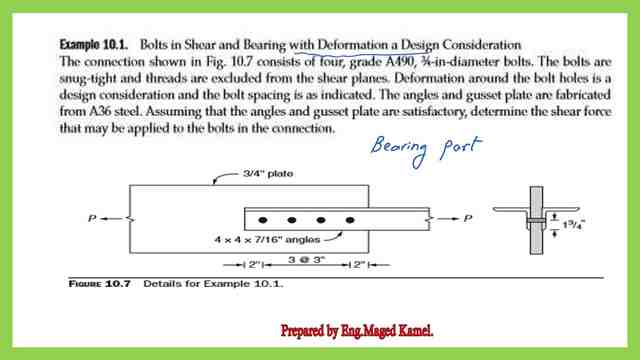

We are going to check the solved problem 10-1, for the bearing and tear-out part from Prof.Alan Williams’s book. the second part will estimate the shear force applied to a connection based on the bearing and tear-out of bolts.

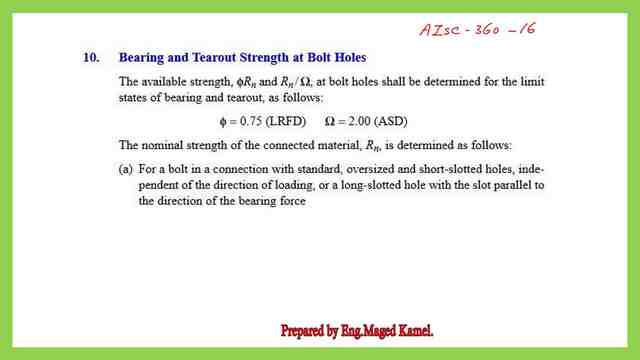

Review of the necessary tables that are needed for the bearing nominal strength estimation.

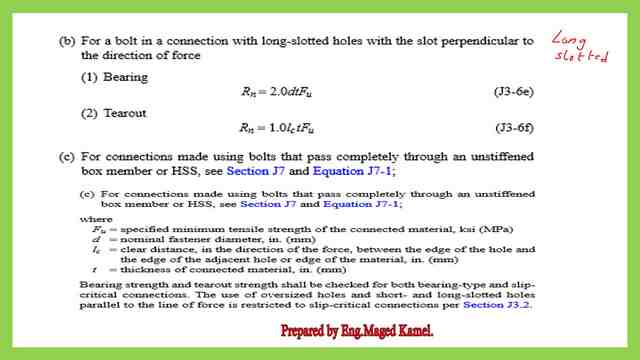

The bearing and Tear-out coefficients for LRFD and ASD, for φ it is=0.75, and for Ω it is=2.0. These coefficients are identical to the coefficients used to estimate shear from bolts.

The AISC code specifics the bearing and tear out, if the deformation under consideration is a design criterion.

Deformation =0.25″, then the upper limit for bearing =2.4*d*t*Fu, where d is the diameter of the bolt, t is the thickness of the plate, Fu is the ultimate strength. But if the deformation is not a design criterion, then, a higher value is given for Rn=3.0dt*Fu.

For non-design criteria in the tear-out, then while evaluating Rn it is= 1.50*Lc*t*Fu.

There is a part for the long slotted, For the bearing and tear-out values.

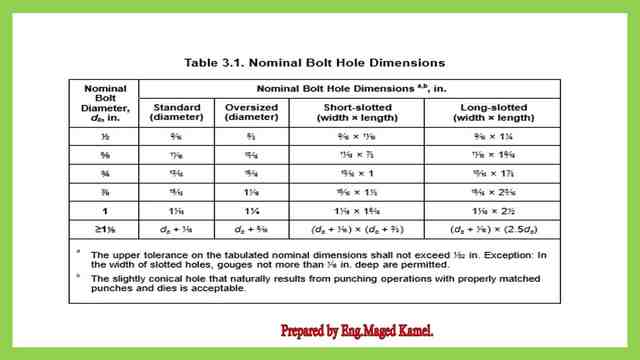

The nominal bolt-hole dimension.

These are the nominal Hole dimensions, for standard dia, we add (1/16′) for evaluating the hole diameter. There are values for oversize,short-slot, and long-slot values.

The same table but, quoted from the bolt council.

The spacing distance between bolts S is to be taken as 2 2/3*db and the minimum clear spacing preferalable=3d.

While the internal clear distance between inner bolts should not be <d. The minimum edge distance for the case of bolt diameter=3/4″ is given in Table J3-4.

A solved problem 10-1- how to get the value of bearing value-LRFD for a connection?

We will start in the second part of the solved problem 10-1. The question is about which thickness to be considered while estimating the bearing. We have two angles and one plate, then in the case of the bearing.

The answer to that question is to select the lowest thickness 3/4″, the plate thickness, or the summation of the thickness of the two angles (2*7/16)=14/16=7/8 “. Since 3/4″<7/8”, then we will select the plate to consider for bearing calculation.

For the edge distance Lc =2″-0.50*dh, the hole diameter dh is (3/4+1/16)=13/16″. lc=2″-0.50*13/16=1.59″>1.

While the internal clear distance =3″, the clear inner distance=3″-(13″/16)=2.1875″ repeated two times and followed by the edge distance.

We consider the plate, This is the appropriate sketch for the arrangement of bolts for a gusset plate. We will write all the previous data, lco, and steel grades of the plate. ASTM A-36 for plate and angles, lco and steel grade, the inner clear distance between bolts, and the inner clear distance between bolts.

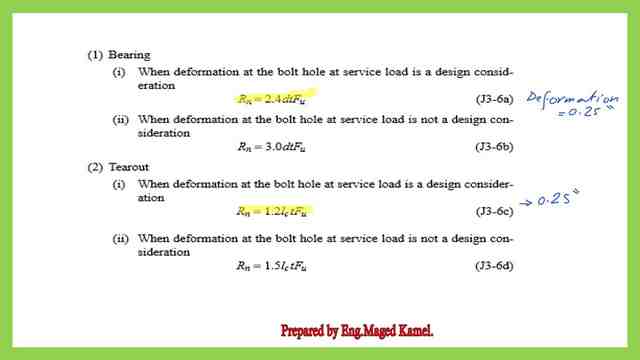

Based on the calculation for the edge bolt the nominal value for Rnb value for the edge bolt is estimated from the relation (1.2*loc*tpl*Fu). the value is estimated as equal to 83 kips. We compare the edge nominal value with the upper limit which is(2.4*d*tp*Fu) which is equal to 78.30 kips. We find that the upper limit value is less than the tear-out nominal value and it will govern the design.

Based on the calculation for the inner bolts the nominal value for Rnb value for the inner bolts lt is estimated from the relation (1.2*lic*tpl*Fu). the value is estimated as equal to 114.21 kips. We compare the edge nominal value with the upper limit which is equal to 78.30 kips. We find that the upper limit value is less than the inner bolts nominal value and it will govern the design.

Now we can see the values of bearing force for each bolt based on both the LRFd and ASd designs.

Using Table 7-4 for the Nominal value of the bearing value-LRFD for inner bolts.

Table 7-4 will give the available bearing strength at bolt holes, the table gives the value for one bolt and the value is per inch of the bearing area.

We have symbols STD, which is a standard hole, and SSLP which is short-slotted plus other items located at the table. The LRFD and ASD values are also shown in the table as 0.75 and 2.00 respectively. We have a table that does not deal with clear distance.

The second column is for bolt spacing inner spacing, two values are given as 2. 2/3*db and 3*db. We have db=3/4″, and the spacing between bolts is 3″.

In the third column, there are two values of Fu, for the guest plate A36 is given, Fu =58 ksi, we will select 3″ spacing and Fu=58 ksi, we draw a line that intersects with the line from the column of 3/4″ as nominal bolt diameter.

We get φRn =78.30 kips/ inch, so we will multiply by gusset plate thickness which is 3/4″= 78.303/4=58.73 kips for one bolt, then multiply by 3 inner bolts=3*58.73=176.19 kips.

Using Table 7-5 for the Nominal value of the bearing value-LRFD for external bolts.

The next table is table 7-5, we will do the same steps. We have the edge distance as 2″ from the cl of the external bolt to the edge, Fu=58 ksi, db=3/4″, the intersection will give φ*Rn=78.30 kips/ inch.

Then multiply by 3/4″ for plate thickness by the number of bolt n, which is=1.

φ*Rn=78.3*3/4*1=58.73 kips .The total sum of φ*Rn=235 kips.Which matches our previous calculations.

In the next post, we will estimate the ASD value of bearing and find out which governs the force value permitted for the connection. Thank you.

This is a link to the first part of the same solved problem, how to get the shear value?

This is a very useful source for the design of various Steel elements, A Beginner’s Guide to the Steel Construction Manual, 15th ed, Chapter 4 – Bolted Connections.

The next post is How to get the value of bearing-ASD 3-3?